From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-30 Origin: Site

Content Menu

● Understanding Hole and Shaft Fit in CNC Machining

● Why Hole-Shaft Fit Matters in CNC Machining

● ISO Fit System and Tolerances in CNC Machining

● Factors Affecting Hole-Shaft Fit in CNC Machining

● Step-by-Step Guide to Achieving Hole-Shaft Fit in CNC Machining

>> Step 1: Identify Functional Requirements

>> Step 2: Set Machining Tolerances in CAD/CAM

>> Step 3: Choose the Proper Machining Method

>> Step 4: Control the Cutting Environment

>> Step 5: Use Proper Measurement and Inspection Tools

>> Step 6: Assembly and Validation

● Tips for Optimizing CNC Machining Fits

● Material Considerations for Hole-Shaft Fit

● Surface Roughness and Its Role in CNC Fits

● Common Problems and Their Solutions

● Quality Control and Statistical Monitoring

● Advanced CNC Machining Techniques for Tight Fits

● FAQ

>> (1) What is a hole-shaft fit in CNC machining?

>> (2) How do I decide which fit type to use?

>> (3) What tolerance notations are common in CNC machining?

>> (4) How can temperature affect fits during machining?

>> (5) What tools measure hole-shaft fits accurately?

Precision and fit are the foundation of functional component assembly in modern CNC machining. Among the many engineering parameters that determine the quality of a CNC-machined part, the relationship between a hole and its mating shaft is one of the most critical. Whether you're producing gears, housings, pulleys, or bearing seats, achieving the correct hole-shaft fit ensures performance, reliability, and long-term stability.

This article explains, in detail, how to achieve the correct hole-shaft fit for CNC machining, including the role of tolerances, measuring systems, machining steps, material effects, and quality assurance. You'll also learn practical machining techniques and inspection tools that ensure your CNC machining jobs meet design intent every time.

The concept of a hole and shaft fit describes how tightly or loosely two cylindrical components fit together — a hole (internal feature) and a shaft (external feature). In CNC machining, where precision is often measured in micrometers, fits determine not only whether parts can be assembled but also how they behave under stress, rotation, and temperature changes.

There are three primary types of fits used in CNC machining:

- Clearance fit: The shaft is always smaller than the hole. This type allows free movement or sliding with minimal friction.

- Transition fit: A controlled overlap—sometimes clearance, sometimes interference—used when accurate location is required without a tight press.

- Interference fit: The shaft is slightly larger than the hole, creating a press fit that requires force or thermal expansion during assembly.

Each of these plays a distinct role in mechanical systems. For example, bearing mounts often rely on interference fits, while gear shafts may require transition fits to allow proper alignment without loosening under load.

The correct hole-shaft fit impacts not only the mechanical performance of a part but also its production cost, assembly efficiency, and service life. High-accuracy CNC machining provides the control needed to achieve consistent fits across large production batches.

An incorrect fit can result in several serious issues:

- Increased vibration or noise during operation.

- Excessive wear and premature component failure.

- Heat generation due to friction or misalignment.

- Dimensional instability under load.

- Difficulty in disassembly or maintenance.

Conversely, a well-machined fit maximizes energy transfer efficiency, ensures smooth motion, and reduces the risk of failure in mechanical equipment.

CNC machining follows standardized systems, such as ISO 286 or ANSI B4.1, to ensure tolerance consistency between mating parts regardless of manufacturer or region. A tolerance system defines the acceptable dimensional variation between the hole and shaft.

Each fit is represented with a notation such as H7/g6 or H8/f7, which indicates tolerance limits:

- The capital letter designates the hole tolerance zone (H means zero lower limit).

- The lowercase letter refers to the shaft tolerance.

- The number indicates the grade of precision (lower numbers = tighter tolerance).

For example:

- H7/g6 → transition fit commonly used in machinery assemblies.

- H8/f7 → clearance fit for easy sliding parts.

- H7/p6 → interference fit for firmly fixed joints.

Properly applying these tolerance combinations ensures that every CNC-machined component fits correctly when assembled.

Achieving accurate hole-shaft fits in CNC machining depends on a variety of factors. Some of the most influential include:

1. Machine condition and precision: CNC equipment must have minimal runout and vibration. Periodic calibration using laser or ballbar testing ensures repeatability.

2. Tool wear and quality: Worn tools produce dimensional drift. Regular inspection using tool setters or laser measurement prevents this issue.

3. Material characteristics: Metals expand differently under heat. Aluminum requires temperature compensation, while steel maintains better dimensional stability.

4. Cutting parameters: Feed rates and spindle speeds influence surface accuracy and roundness.

5. Environmental conditions: Temperature fluctuations in the workshop alter the final size due to thermal expansion.

By monitoring these factors and applying precision control at every step, machinists can consistently produce components that meet tolerance requirements.

Before machining begins, define the type of movement or hold required between the hole and shaft. Consider operating speed, load, thermal conditions, and service environment.

- Loose clearance fits (e.g., H9/e9) are ideal for rotating shafts in sliding connections.

- Medium transition fits (e.g., H7/g6) are used for centering couplings.

- Tight interference fits (e.g., H7/p6) provide secure press connections.

Understanding function prevents over-tolerancing, which can drive up costs unnecessarily.

Enter the correct tolerance values in the CAD drawing or directly in the CAM system. Modern software like Fusion 360, SolidWorks CAM, or Mastercam integrates tolerance-based machining strategies, automatically adjusting toolpaths to maintain specified limits.

Using GD&T (Geometric Dimensioning and Tolerancing) ensures that hole axes, roundness, and concentricity conform to design intent, not just basic size.

CNC machining provides several ways to achieve accurate hole and shaft dimensions:

- For holes:

- Drilling for rough removal.

- Boring for concentricity improvement.

- Reaming to achieve final size and surface finish.

- CNC grinding for sub-micron final adjustments.

- For shafts:

- CNC turning for precision diameters.

- Cylindrical grinding for achieving interference or transition fits.

- Polishing for fine-tuned surface roughness.

Each step progresses towards the target tolerance, with finishing processes refining the result to exact specifications.

Temperature and cutting conditions have a direct effect on the outcome of CNC machining fits. Always maintain:

- Stable machining temperature (20°C ± 2°C recommended).

- Consistent coolant flow to reduce thermal distortion.

- Balanced cutting tools for smoother surface texture.

- Minimum tool deflection using proper fixturing and short overhangs.

Precision is achieved through environmental stability as much as through machine accuracy.

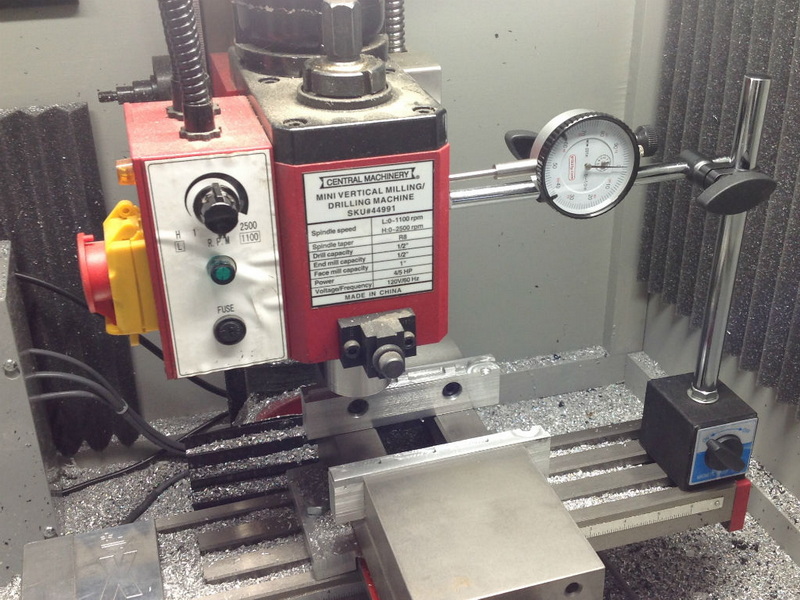

Measurement accuracy is crucial in verifying a proper hole-shaft fit. Common inspection equipment includes:

- Micrometers and calipers for basic dimension checks.

- Plug or ring gauges for go/no-go verification.

- Coordinate Measuring Machines (CMMs) for complete 3D geometry assessment.

- Surface finish testers to confirm roughness within specifications.

For high-volume production, inline CNC probing systems can measure dimensions automatically before removing the part from the fixture, significantly reducing rework.

Final part assembly tests the success of the CNC machining operation. During assembly:

- For interference fits, use thermal techniques—heating the housing or cooling the shaft (liquid nitrogen or freezer)—to allow easier insertion.

- For transition fits, apply light pressing using precision alignment fixtures.

- For clearance fits, ensure free rotation without excessive axial play.

After assembly, check for vibration, mismatch, and axial alignment. Proper validation ensures the machining process has achieved its intended fit performance.

- Use reaming instead of drilling for final hole finishing; it improves diameter accuracy.

- Perform roughing and finishing on separate setups to avoid thermal buildup.

- Use CNC adaptive control to automatically adjust parameters during cutting.

- Monitor tool wear using smart tool management systems.

- Design with manufacturability in mind—avoid unnecessarily tight tolerances if not functionally essential.

Integrating these practices allows you to achieve balance between cost, precision, and machining time.

Choosing the right material pair between hole and shaft is an essential factor in CNC machining. Typical material combinations include:

| Hole Material | Shaft Material | Typical Fit Type | Remarks |

|---|---|---|---|

| Aluminum alloy | Steel | H7/g6 | Lightweight structures |

| Stainless steel | Stainless steel | H7/p6 | High strength, corrosion resistant |

| Cast iron | Bronze | H8/f7 | Bearing housings |

| Titanium alloy | Hardened steel | H7/n6 | Aerospace assemblies |

Each combination affects thermal stability, machining ease, and part longevity. Always design with material compatibility in mind, particularly when operating under varying temperatures.

Surface roughness determines how well two parts contact each other during assembly. For critical fits:

- Clearance fits: Ra 1.6–3.2 µm

- Transition fits: Ra 0.8–1.6 µm

- Interference fits: Ra 0.2–0.8 µm

CNC grinding and lapping operations produce the best results where smooth finishes are vital, such as hydraulic systems or rotating shafts.

| Problem | Possible Cause | Solution |

|---|---|---|

| Hole diameter oversize | Tool wear or chatter | Use sharper reaming tools and slower feed rates |

| Shaft too large | Incorrect tool offset | Adjust CNC offset and verify tool compensation |

| Rough surface finish | Wrong cutting speed | Optimize spindle speed and apply coolant |

| Oval holes | Machine vibration | Reinforce fixturing and check spindle alignment |

| Assembly too tight | Thermal expansion mismatch | Adjust temperature during assembly process |

Preventive process monitoring and quick corrective measures help maintain consistency across all production runs.

High-precision CNC machining facilities often employ Statistical Process Control (SPC) and Six Sigma methodologies to maintain stable tolerance performance. Real-time data collection from machine sensors, such as spindle load and temperature, enables operators to predict when deviations may occur.

Implementing quality data feedback loops assures that dimensional fits — especially hole and shaft assemblies — remain within tolerance throughout the entire manufacturing cycle.

Some cutting-edge CNC techniques can further improve hole-shaft fits for high-precision industries such as aerospace, robotics, and medical device manufacturing:

- In-process probing: Automatically corrects tool path during machining.

- Thermal compensation algorithms: Adjust dimensions based on machine temperature.

- Ultra-precision diamond turning: Used for extremely tight fits in optical and electronic components.

- CNC grinding and honing: Achieve mirror finishes and sub-micron accuracy.

By combining these innovations, CNC machining continues to push the limits of mechanical precision.

Achieving the perfect hole-shaft fit for CNC machining requires understanding fit types, tolerance systems, machining parameters, and inspection procedures. Every stage — from CAD model design to post-processing — contributes to the final accuracy of the part.

CNC machining allows manufacturers to repeatedly produce components that meet the strictest dimensional standards. By following controlled machining steps, using high-quality tools, maintaining stable conditions, and implementing proper measurement techniques, you can ensure reliable assembly, optimal performance, and long-lasting durability of all mechanical components.

Contact us to get more information!

It defines how closely a hole and its mating shaft fit together, determining clearance or interference for proper assembly.

Choose clearance fits for free movement, transition fits for accurate centering, and interference fits for secure, permanent joints.

Notations like H7/g6, H8/f7, and H7/p6 represent standard ISO fits, specifying how large or small the hole and shaft may be.

Heat expansion changes part size. Use coolant, minimize long cutting cycles, and maintain ambient temperature for stable accuracy.

Plug gauges, micrometers, and coordinate measuring machines (CMMs) are the most reliable instruments for fit verification.

1. (https://www.iso.org/standard/74363.html)

2. (https://www.asme.org)

3. (https://www.engineeringtoolbox.com/iso-hole-shaft-tolerances-d_781.html)

4. (https://www.machiningdoctor.com)

5. (https://metalcutting.com)

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.