From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-28 Origin: Site

Content Menu

● What Is a CNC Milling Machine?

● Why Amazon Is the Ideal Platform for CNC Products

>> Key Advantages of Selling CNC Products on Amazon:

● Step-by-Step Guide: How to Profit from CNC Milling on Amazon

>> Step 1. Research Profitable Niches

>> Step 2. Master Product Design and Prototyping

>> Step 3. Source Reliable Materials

>> Step 4. Optimize Your Amazon Listing for Conversion

>> Step 5. Calculate Costs and Set Profitable Prices

>> Step 6. Fulfillment by Amazon (FBA) Strategy

>> Step 7. Develop a Marketing Plan

>> Step 8. Improve Efficiency and Scale Production

● Best Types of CNC Milling Products to Sell on Amazon

● Managing Production and Quality Assurance

● Common Mistakes to Avoid When Starting

● FAQ

>> 1. What types of products can I sell with a CNC milling machine on Amazon?

>> 2. Do I need industrial machinery to start?

>> 3. How do I handle shipping if using FBA?

>> 4. How do I improve my machining efficiency?

>> 5. What makes CNC products appealing to Amazon customers?

Selling on Amazon has opened up countless opportunities for creative entrepreneurs and small-scale manufacturers. With today's technology, it's easier than ever to produce customized, high-quality items using a CNC milling machine and sell them directly to a global audience. Instead of depending on middlemen or wholesalers, you can manufacture precision parts and market them as unique Amazon listings — appealing to both consumers and industrial buyers.

In this guide, you will learn practical steps on how to make money on Amazon with a CNC milling machine, including product development, cost management, listing optimization, and marketing strategies. By the end, you'll understand exactly how to turn your machining skills into a profitable online business.

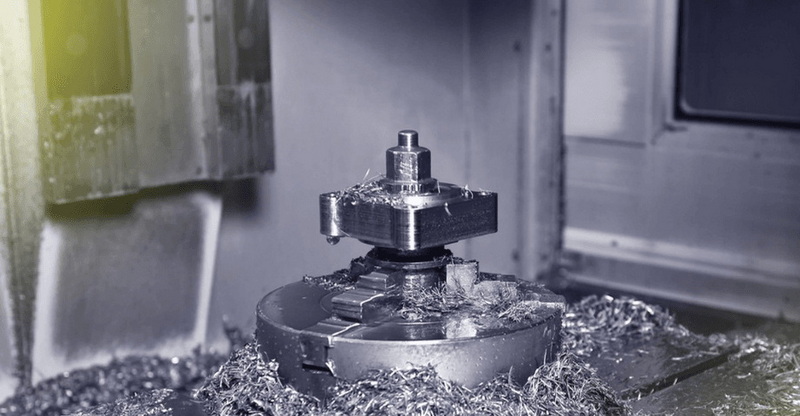

A CNC milling machine (Computer Numerical Control) is a computer-operated manufacturing tool used to cut, engrave, and shape materials such as metal, wood, or plastic. It follows programmed digital commands to create precise designs automatically, eliminating the need for manual machining.

CNC milling machines range from desktop-sized hobby models to heavy-duty industrial setups. Regardless of scale, they offer the same core benefits:

- Highly accurate and consistent production for repetitive tasks.

- Ability to create intricate shapes and patterns that manual tools cannot achieve.

- Efficiency and reduced labor costs for small-batch or custom production.

- Ideal integration with CAD/CAM software for design flexibility.

For entrepreneurs, a CNC milling machine bridges the gap between custom craftsmanship and scalable production — an ideal combination for an Amazon-based business.

Amazon remains one of the most powerful e-commerce ecosystems on the planet, attracting over 300 million active users worldwide. Its platform allows artisans, engineers, and small manufacturers to reach a massive customer pool without building their own online store from scratch.

- Global Exposure: Your CNC machined items can reach buyers internationally with minimal marketing costs.

- Trust and Credibility: Amazon's reputation boosts consumer confidence in purchasing from new sellers.

- Flexible Shipping: Options like Fulfillment by Amazon (FBA) handle delivery, warehousing, and returns.

- Brand Opportunities: Through Amazon Brand Registry, you can create a professional brand identity and protect your intellectual property.

When paired with efficient CNC milling machine production, Amazon provides a streamlined sales pipeline from manufacturing to customer delivery.

Start your business by identifying profitable product niches that align with your machining capabilities. Focus on specialized items that are difficult to mass-produce but valuable to niche markets. Popular categories include:

- Automotive or motorcycle components (e.g., brackets, handles, mountings).

- Industrial machine parts and replacement components.

- Custom aluminum housings or enclosures for electronics.

- Metal or wood art pieces and home décor.

- Personalized gifts and accessories (keychains, nameplates, or engraved tools).

Tools like Jungle Scout, Helium 10, and AMZScout can help you gauge demand, competition levels, and pricing ranges. The secret is to find products that justify the precision and customization power of a CNC milling machine.

Once you know your niche, the next step is designing the product. Use CAD software such as SolidWorks, Fusion 360, or AutoCAD to model the item in 3D. Generate prototypes on your CNC milling machine to test material strength, surface finish, and functionality.

During this process, aim for:

- Design simplicity: Balanced complexity enhances appearance but reduces cycle time.

- Material optimization: Choose affordable yet durable materials that appeal to customers.

- Consistency: Make sure each prototype meets identical standards before scaling.

Efficient prototyping saves time and resources once you enter full production.

Your profitability depends on smart material sourcing. Identify local or international suppliers who offer high-quality aluminum, brass, copper, steel, or composite materials in bulk. Purchasing larger quantities often qualifies you for wholesale pricing discounts.

Don't ignore secondary materials like cutting fluids, tool inserts, fixtures, and coatings. Each detail affects the efficiency of your CNC milling machine and the aesthetics of the final product.

Presentation matters as much as production quality. A well-optimized Amazon listing can dramatically boost conversion rates. Focus on the following elements:

- Title Optimization: Include descriptive keywords such as “CNC milled,” “precision-machined,” or “custom aluminum part.”

- Compelling Images: Use high-resolution photos from multiple angles, highlighting the precision finish.

- Detailed Bullet Points: Explain material type, machine process, and the unique advantages of your design.

- Keyword-Rich Descriptions: Integrate “CNC milling machine” naturally throughout your content for SEO ranking.

- Customer Reviews: Encourage early buyers to leave feedback — credibility drives more sales.

Your listing should make customers feel confident that they are buying professional-grade, machine-precise items.

Profitability starts with accurate cost accounting. When calculating product price, include:

- Material expenses (metal blocks, cutting tools, consumables).

- CNC milling machine operation costs (power consumption, wear, maintenance).

- Design and labor input.

- Amazon seller fees and FBA logistics charges.

A good target is at least a 40–50% gross profit margin to maintain flexibility during price competition or marketing campaigns.

Fulfillment by Amazon allows sellers to send bulk inventory to Amazon's warehouses, where all storage, packaging, delivery, and returns are managed automatically. For a CNC-based business, this system has several benefits:

- You can batch-produce items on your CNC milling machine and ship them in bulk.

- Amazon ensures fast Prime shipping, improving customer satisfaction.

- Your workload decreases significantly, letting you focus on production and design.

It's essential to follow Amazon's packaging and labeling guidelines to qualify for FBA. Include small-branded inserts or business cards promoting your machine shop's story for additional branding value.

Even if you use Amazon's internal traffic, external marketing helps boost visibility and improve keyword ranking. You can market your CNC milling machine products in several effective ways:

- Video Content: Showcase machining processes on YouTube or TikTok — audiences love precision manufacturing videos.

- Social Media Advertising: Use Instagram and Facebook ads to highlight craftsmanship and innovation.

- Google SEO and Blogs: Create educational content about CNC machining, driving organic traffic to your Amazon Storefront.

- Email Campaigns: Keep buyers informed about new product launches or limited-edition items.

Your goal is to establish brand authority — being perceived not only as a seller but as a skilled CNC manufacturer.

Once sales stabilize, reinvest profits into better tooling, automation, or new CNC models. Upgrading to a multi-axis CNC milling machine offers greater design flexibility and quicker turnaround.

Additional techniques to scale include:

- Using automated tool changers to reduce downtime.

- Implementing productivity software for scheduling and quality control.

- Hiring additional staff or outsourcing finishing processes like polishing or coating.

By scaling progressively, you maintain quality while increasing volume — the key to long-term profitability.

Here are some creative and commercial CNC milling machine product ideas for inspiration:

1. Automotive Accessories – Shift knobs, pedal covers, or logo badges carved from aluminum.

2. Home Décor – Custom brackets, wall-mounted art, and engraved nameplates.

3. Electronics Enclosures – CNC-cut aluminum boxes for DIY tech enthusiasts.

4. Industrial Components – Mounting plates, clamps, fixtures, and tool holders.

5. Art and Jewelry – Intricate designs milled from brass or bronze.

Each of these niches combines engineering accuracy with aesthetic appeal — making them perfect for Amazon sales.

To maintain a solid reputation, your products must meet consistent quality standards. Build a simple quality control process within your production workflow:

- Inspect dimensions and tolerances after every batch.

- Use measurement tools such as calipers and micrometers.

- Keep digital logs for every production run.

- Replace worn-out cutters frequently to maintain sharp edge finishes.

- Apply corrosion protection coatings when required.

A disciplined production routine ensures that every item from your CNC milling machine meets professional-grade standards.

While many entrepreneurs succeed, beginners often face avoidable errors:

- Skipping market research: Not every product benefits from CNC machining — test demand first.

- Underpricing: Failing to include hidden costs like tool wear and energy usage.

- Neglecting branding: Generic listings rarely rank well without a unique brand identity.

- Ignoring customer feedback: Adjusting design or packaging based on reviews builds trust.

- Lack of maintenance: A poorly maintained CNC milling machine will reduce precision and increase rework time.

Learning from these obstacles early helps you achieve steady growth.

A well-optimized CNC Amazon business can achieve high returns once production stabilizes. Small shops often start earning $2,000–$8,000 monthly within six to twelve months of consistent sales. Profit levels depend on:

- Product complexity and uniqueness.

- Machine efficiency and cycle time.

- Cost control (materials, tools, energy).

- Number of active Amazon listings.

- Strength of your marketing funnel.

The capital invested in a CNC milling machine pays off faster when combined with strong branding, repeat buyers, and diversified product lines.

CNC machining is expanding rapidly as product personalization demand increases. From aerospace spare parts to custom smartphone accessories, customers now look for tailored solutions.

Amazon's technology-driven marketplace aligns perfectly with this trend — allowing CNC manufacturers to reach specific audiences wanting unique or custom-fit products.

Investing in CNC milling machine operations today means positioning your business for the growth of precision manufacturing in e-commerce tomorrow.

Turning a CNC milling machine into a profitable Amazon-based business takes planning, skill, and dedication — but it's absolutely achievable. By combining precision engineering with smart e-commerce practices, you can build a sustainable income stream that grows year after year.

Whether you're crafting custom parts, personalized gifts, or industrial components, Amazon gives you direct access to millions of customers. With the right mix of quality, creativity, and marketing, your CNC milling business can become a reliable source of profit and brand recognition worldwide.

Contact us to get more information!

You can sell metal parts, custom components, engraved decorations, home improvement tools, or personalized items like keychains and plaques. Focus on precision and originality.

No. Many small entrepreneurs start with desktop or mid-size CNC mills costing between $2,000 and $10,000. Choose equipment suitable for your target product size and material.

Send inventory batches directly to Amazon warehouses after proper labeling and packaging. Amazon handles storage, delivery, and customer service.

Use sharp cutters, optimized feed rates, and fixtures for consistent positioning. Schedule maintenance regularly to maintain the performance of your CNC milling machine.

Buyers value precision, durability, and customization. By using a CNC milling machine, you can offer products that stand out from mass-produced alternatives.

1. (https://sellercentral.amazon.com)

2. (https://www.autodesk.com/products/fusion-360/overview)

3. (https://www.junglescout.com)

4. (https://www.helium10.com)

5. (https://sellercentral.amazon.com/help/hub/topic/G200141480)

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.