From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-29 Origin: Site

Content Menu

● Understanding Swiss-type CNC Machining

● The Rise of the Iranian CNC Machining Industry

>> Factors Driving Industry Growth

● Leading Swiss-type CNC Machining Manufacturers and Suppliers in Iran

>> 1. Pars Precision Industries

>> 3. AriaTech Precision Components

● Benefits of Partnering with Iranian CNC Manufacturers

● Major Applications of Swiss-type CNC Machining in Iran

>> Electronics and Communications

● Technological Innovations and Trends

● Choosing the Right Swiss-type CNC Supplier in Iran

● Market Potential and Future Outlook

● Frequently Asked Questions (FAQ)

>> Q1: What materials can Iranian Swiss-type CNC manufacturers process?

>> Q2: Can Iranian suppliers meet export quality standards?

>> Q3: What industries use Swiss-type CNC machining the most in Iran?

>> Q4: Are OEM and ODM services available for overseas clients?

>> Q5: How long is the typical production and shipping time?

As global industries become more technology-driven and quality-focused, precision machining stands at the center of advanced manufacturing. Among the methods driving this innovation, Swiss-type CNC machining has become the go-to technology for producing miniature, complex, and high-tolerance parts that meet demanding industrial standards.

Iran, traditionally recognized for its engineering depth and industrial potential, is now emerging as a new hub for Swiss-type CNC machining manufacturers and suppliers. Supported by affordable skilled labor, modern machinery, and a growing export network, Iranian companies are increasingly serving brands, wholesalers, and OEM producers worldwide.

This article provides a detailed overview of the best Swiss-type CNC machining manufacturers and suppliers in Iran, explaining their capabilities, advantages, and the strategic importance of Iran's evolving CNC machining industry.

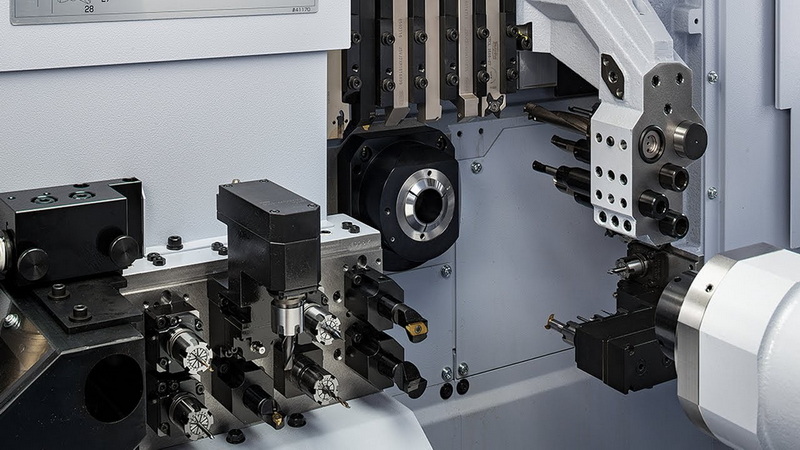

Originally designed in Switzerland over a century ago for the watchmaking industry, Swiss-type CNC machining has evolved into one of the most advanced precision technologies for small, intricate parts. The defining characteristic of this machining type is the sliding headstock mechanism that supports the material close to the cutting tool. This design minimizes workpiece deflection, allowing exceptional accuracy even for parts with diameters smaller than 32 mm.

Key characteristics of Swiss-type CNC machining:

- Exceptional precision and consistency in high-volume production.

- Capability to machine complex geometries in a single setup.

- Superior surface finish and minimal run-out.

- Reduced dimensional errors due to close tool support.

- High material utilization efficiency and minimal waste.

From aerospace fasteners to medical implants, Swiss-type machining provides unmatched reliability. Today, Iranian manufacturers have adopted this technology to meet global standards, combining local technical expertise with imported equipment from Japan, Switzerland, and China.

Over the past decade, Iran's manufacturing sector has undergone a quiet transformation. Despite international challenges, the country has invested heavily in industrial automation, education, and precision manufacturing technology. As a result, several Iranian machining companies have begun exporting precision components to Europe, the Middle East, and Asia.

1. Modern Equipment Adoption:

Iranian factories now operate top brands of Swiss-type CNC machines such as Citizen, Star, and Tsugami. These machines provide multi-axis control and automated tool changers, offering high accuracy and productivity.

2. Skilled Technical Workforce:

Iran graduates thousands of mechanical and manufacturing engineers every year, building a pool of technicians capable of handling complex CNC operations and CAD/CAM designs.

3. Cost Efficiency and Strategic Location:

Iran's labor and operational costs remain significantly lower than in Western countries, allowing competitive pricing without compromising quality. Its central location also enables easy access to Europe, Central Asia, and the Persian Gulf.

4. Government Support for Industrial Growth:

Several industrial free zones and export promotion programs encourage foreign collaboration and technology transfer in CNC machining, paving the way for sustained growth.

Below are some of the top-performing Swiss-type CNC machining manufacturers and suppliers in Iran, recognized for their innovation, export capability, and commitment to precision.

Pars Precision Industries is a leader in fine-tolerance machining using high-end Swiss-type lathes. The company specializes in producing stainless steel, titanium, brass, and aluminum parts for aerospace and medical equipment industries.

Key services:

- OEM/ODM partnerships for foreign brands.

- Multi-axis turning for micro-components.

- Full inspection reports and traceability system.

Pars Precision's export department ensures timely international delivery, with multilingual engineers available for overseas clients.

Located in the industrial area near Tehran, this company offers complete CNC machining services using Citizen and Star machinery. It provides digital product design support and automated inspection for aerospace and automotive projects.

Advantages:

- ISO 9001-certified quality system.

- Flexible MOQ and fast prototyping.

- Advanced CMM and 3D measurement facilities.

Tehran CNC System Co. has established long-term contracts with European and regional manufacturers, demonstrating its reliability in precision production.

AriaTech combines cost efficiency with innovation. Their factory integrates ERP-controlled production management, offering transparency and efficiency at every stage. They serve sectors including telecommunications, defense, and heavy machinery.

Key highlights:

- Precision machining for parts from 1 mm to 25 mm diameter.

- Batch consistency for serial production.

- Excellent surface finishing and deburring quality.

The company also provides after-sale engineering consultation for product modifications and tooling optimization.

Sahand has positioned itself as one of the first partially automated CNC machining facilities in northern Iran. It integrates robotic part feeding systems, increasing production speed and consistency.

Key highlights:

- High production volumes with 24/7 operation.

- Experience across automotive, valve, and electronics industries.

- Bilingual technical support for international customers.

Additionally, the group's in-house tool maintenance division ensures long tool life and dimensional stability across all batches.

Operating from Isfahan, IranTech focuses on sustainable production practices. Their advanced Swiss-type CNC machining lines use material optimization software to reduce waste by up to 30%.

Key highlights:

- Eco-friendly machining using high-precision feed controls.

- Micron-level accuracy across all materials.

- Documentation compliant with EU and Middle Eastern import standards.

IranTech's growing network of clients includes buyers from Turkey, the UAE, and Germany, reflecting its rising international credibility.

Iran's Swiss-type CNC machining manufacturers and suppliers offer a balanced mix of quality, affordability, and technical expertise. International buyers sourcing CNC parts from Iran enjoy several competitive advantages:

- Cost-Effective Precision Production: Due to lower overhead, Iranian factories can deliver high-precision components at rates 20–40% lower than typical EU suppliers.

- Strong Engineering Capabilities: Many companies collaborate with university research centers to develop advanced materials and machining techniques.

- OEM & ODM Flexibility: Custom production according to client drawings, prototypes, or 3D models is widely supported.

- Short Lead Times: With modern logistics routes through the Persian Gulf, delivery to Asian and European markets is faster than ever.

- Commitment to Quality Control: Many factories implement 100% part inspection using vision measuring systems and laser gauging technology.

Precision and safety define aerospace manufacturing. Iranian suppliers use Swiss-type CNC machining to produce fuel injectors, turbine parts, shafts, and fasteners with tight tolerances suitable for jet engine applications.

Iran's medical technology sector increasingly depends on precision-machined orthopedic pins, titanium bone screws, and surgical tool components, all produced by ISO-certified CNC workshops.

Automotive suppliers in Iran use Swiss-type lathes to manufacture injectors, fittings, sensor housings, and brake system components. Their capability for automation and high-volume production attracts regional car brands.

With the global boom in electronics and microdevices, Swiss-type CNC machining supports the production of microswitch parts, terminals, and precision pins required in PCB assembly and telecom systems.

Iran's vast energy sector demands specialized machined fittings resistant to pressure and corrosion. Swiss-type machining ensures the reliability needed for subsea, refinery, and hydraulic applications.

Iranian Swiss-type CNC machining suppliers are adopting new technologies to enhance quality and efficiency. These include:

- Computer-Aided Manufacturing (CAM): Enhancing tool paths and cycle time optimization.

- Automation Integration: Implementing loading robots and digital monitoring systems for consistent performance.

- Predictive Maintenance: Using IoT sensors to track spindle wear and cutting conditions.

- Green Machining: Applying coolant recycling systems and minimizing environmental impact.

These innovations have positioned Iranian suppliers as credible partners for global manufacturing projects focused on sustainability and smart production.

For international buyers seeking quality and reliability, supplier selection is crucial. Here are essential steps to help you find the ideal manufacturing partner:

1. Evaluate Equipment and Capability: Confirm availability of multi-axis Swiss machines and precision testing tools.

2. Verify Certifications: Look for ISO 9001, ISO 13485, or AS9100 certifications depending on your industry.

3. Request Product Samples: Assess machining precision, surface finish, and assembly compatibility.

4. Clarify Logistics and Terms: Discuss Incoterms, shipping schedules, and inspection options.

5. Assess Communication and Support: A responsive, English-speaking team is essential for seamless cooperation.

By following these steps, global manufacturers can confidently partner with Swiss-type CNC machining manufacturers and suppliers in Iran for both small-scale prototyping and large serial production.

Iran's precision machining sector is forecasted to expand significantly over the next ten years. Key factors supporting this trajectory include:

- Industrial modernization programs emphasizing automation and export efficiency.

- Increased demand from neighboring markets like Turkey, the UAE, and India for precision-engineered components.

- Rising collaboration opportunities between Iranian factories and overseas engineering consultants.

- Focus on sustainability and eco-efficiency to meet global procurement standards.

With these developments, Iran's Swiss-type CNC machining manufacturers and suppliers are expected to become regional powerhouses serving industries that demand both quality and economic value.

Iran's precision manufacturing industry is entering a new era, defined by technical skill, modern equipment, and cost-efficiency. The steady rise of Swiss-type CNC machining manufacturers and suppliers marks the country's transition toward high-value industrial production.

These manufacturers combine the precision of advanced Swiss machines with Iran's engineering depth, delivering global-standard components at competitive prices. The future of Iran's CNC machining sector will depend on continuous investment, international cooperation, and modernization—but its current progress already positions it as one of the most promising precision manufacturing markets in the Middle East.

For global brands, wholesalers, and manufacturers looking for reliable outsourcing partners, Iran's Swiss-type CNC machining manufacturers and suppliers offer a perfect combination of quality, adaptability, and cost advantage—an opportunity worth exploring.

Contact us to get more information!

A1: They commonly machine stainless steel, aluminum, titanium, brass, copper, and engineering plastics such as PEEK or Delrin.

A2: Yes. Many leading suppliers are ISO 9001 or CE certified, and several are moving toward AS9100 for aerospace and ISO 13485 for medical components.

A3: Aerospace, automotive, medical, and electronics are the primary users, followed by oil and energy machinery sectors.

A4: Absolutely. Most Swiss-type CNC machining manufacturers and suppliers in Iran offer engineering assistance, prototype creation, and private labeling.

A5: For sample batches, production normally takes 10–15 days. Mass production runs vary from 3 to 6 weeks, depending on part complexity and material.

1. https://www.machinerynetwork.com

2. https://www.globalspec.com

3. https://www.machinedesign.com

4. https://www.globalsources.com

5. https://www.mfg.com

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.