From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-27 Origin: Site

Content Menu

● Average CNC Machining Cost Per Hour in India

● Key Factors That Influence CNC Machining Costs

>> Machine Type and Configuration

>> Part Complexity and Precision Requirements

>> Machine Setup and Programming Time

● Regional Variations Across India

● CNC Machining Cost Comparison: India vs. Other Countries

● Hidden Costs Often Overlooked in CNC Machining

● Tips to Reduce CNC Machining Costs

● Future Trends Impacting CNC Machining Costs in India

>> Automation and Smart Manufacturing

>> Sustainability and Energy Efficiency

● How to Choose the Right CNC Machining Supplier in India

● FAQ

>> 1. What is the average CNC machining cost per hour in India?

>> 2. Why is CNC machining in India more affordable?

>> 3. Does part complexity affect machining cost?

>> 4. What measures can help reduce CNC machining costs?

>> 5. Are Indian CNC machining companies reliable for exports?

India has become one of the fastest-growing hubs for high-precision manufacturing. Among various advanced manufacturing techniques, CNC machining stands out as a vital process for creating precision-engineered components used in industries such as automotive, aerospace, electronics, energy, and medical devices.

Understanding how much CNC machining costs per hour in India is crucial for engineers, procurement managers, and overseas buyers who wish to source parts efficiently. The cost per hour can vary significantly depending on machine type, part complexity, material, and region. This article explores every cost factor in detail and provides practical insights to help you budget for CNC machining projects more effectively.

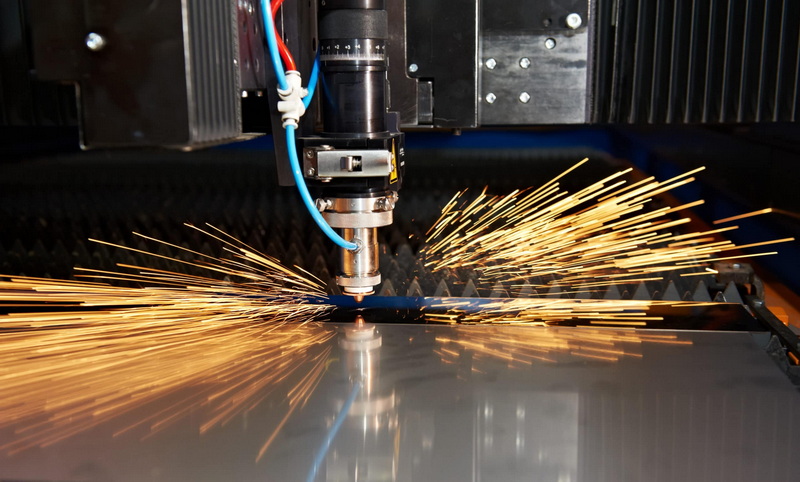

CNC machining (Computer Numerical Control machining) is a subtractive manufacturing process where pre-programmed computer software controls the movement of factory tools and machinery. It transforms raw materials like metal or plastic into precise shapes through operations such as milling, turning, drilling, and grinding.

CNC machines can follow exact digital models, ensuring consistent accuracy across mass production runs. They are widely used for both prototyping and high-volume production where precision and repeatability are essential. CNC machining in India has evolved immensely over the past decade, as local manufacturers have adopted modern systems, 5-axis machines, and CAD/CAM integration technologies comparable to those used internationally.

The CNC machining cost per hour in India generally ranges between ₹400 and ₹1,200 INR ($5 – $15 USD). High-end or specialized operations, like aerospace component machining or titanium part production, can go up to ₹2,000 INR ($25 USD) per hour.

Below is an indicative breakdown of typical costs:

| Type of CNC Machine | Typical Hourly Rate (INR) | Typical Hourly Rate (USD) |

|---|---|---|

| 3-Axis CNC Milling Machine | ₹400 – ₹700 | $5 – $9 |

| 4-Axis CNC Machining Center | ₹700 – ₹1,000 | $9 – $12 |

| 5-Axis CNC Machining Center | ₹1,000 – ₹2,000 | $12 – $25 |

| CNC Turning Lathe | ₹500 – ₹800 | $6 – $10 |

| Swiss-Type Precision Lathe | ₹900 – ₹1,500 | $11 – $18 |

These rates are averages based on Indian machine shops serving industrial and export clients. The exact CNC machining cost per hour depends on technological capability, operator skill, and the complexity of the product.

Machine selection is the first and most influential factor.

- 3-axis CNC milling machines are the most common and affordable option for basic cutting and drilling tasks.

- 4-axis and 5-axis machines allow intricate contours, undercuts, and multi-face machining without manual repositioning, greatly reducing setup time but increasing hourly cost.

- CNC turning centers are ideal for producing cylindrical parts at moderate cost.

- Swiss-type lathes, used for micro-components in electronics or medical sectors, have higher precision and thus higher operation charges.

More complex parts require multiple tool changes, advanced programming, slower feed rates, and tighter tolerances. For instance, a simple aluminum bracket might cost ₹500/hour on a 3-axis machine, while a multi-feature aerospace part with ±0.01 mm tolerance could exceed ₹1,500/hour. The more intricate the geometry, the longer the machining cycle time, which directly influences hourly costs.

Material properties influence both machining speed and tool life.

- Aluminum is light and easy to cut, thus most affordable.

- Mild steel and copper have moderate machining costs.

- Stainless steel, Inconel, titanium, or hardened steel require slower speeds and special tooling, greatly increasing both machining time and tool wear.

- Engineering plastics such as ABS, Nylon, or PEEK are faster to machine, reducing cost per hour.

Material waste also impacts overall costing. Machining hard metals often leads to higher material removal rates and increased scrap waste, which indirectly adds to project cost.

Skilled CNC operators, programmers, and quality inspectors are critical for maintaining precision and machine uptime. Though labor costs in India are significantly lower than in the U.S. or Europe, training and technical skill requirements for high-end machining projects add moderate cost. In most Indian manufacturing units, labor input represents 10–20% of the total CNC machining charge.

Before machining begins, setup and programming can take several hours for complex parts. The setup cost is usually distributed across production volume—hence, large batch runs tend to reduce per-piece cost. A prototype or small batch production might incur high hourly costs due to longer setup amortized over fewer parts.

Cutting tool performance affects both quality and operating time. Tool wear, replacement, and maintenance costs are embedded in machine hourly rates. Machining shops with advanced tool condition monitoring systems and spindle diagnostics may charge higher, yet ensure consistent accuracy and reduced downtime.

Electricity tariffs differ by state but form another key factor in CNC machining cost per hour in India. Regions like Maharashtra and Tamil Nadu have higher industrial power rates than others. Overhead costs also include maintenance, floor space, and quality assurance systems.

The hourly cost of CNC machining changes depending on geography and local industrial infrastructure.

- Pune, Bangalore, and Hyderabad: Advanced manufacturing hubs with aerospace and defense machining capability. Rates are higher, around ₹1,000–₹1,800/hr due to high-end machinery and strict quality norms.

- Chennai and Coimbatore: Ideal for automotive and precision engineering components. Hourly rates average ₹600–₹1,000.

- Ahmedabad and Rajkot: Medium-sized shops with strong mechanical manufacturing base; typical rates ₹500–₹900.

- Delhi NCR (Noida, Gurugram): Offers both affordable and export-grade CNC machining services with rates ranging between ₹500–₹1,200 depending on service scope.

Selecting the right region depends on project intent. Prototype or small-batch work can be done economically in mid-tier cities, while industries requiring certification and aerospace-grade precision often choose Bangalore or Pune.

One of India's greatest strengths is its cost advantage over other countries. The table below compares typical hourly machining rates across major manufacturing regions:

| Country | Average CNC Machining Cost Per Hour (USD) |

|---|---|

| India | $5 – $15 |

| China | $8 – $20 |

| Vietnam | $6 – $18 |

| USA | $30 – $100 |

| Germany | $40 – $120 |

| Japan | $45 – $130 |

India provides one of the best cost-to-quality ratios globally. Combined with technologically capable shops, English communication skills, and export experience, Indian CNC machining manufacturers are increasingly sought after by international buyers for both prototype development and large-scale production.

To estimate CNC machining expenses, you can calculate:

Total Cost = (Hourly Rate × Machining Time) + Setup + Material + Post-Processing

For example:

- Machine Rate: ₹600/hour

- Machining Time: 5 hours

- Setup and QA: ₹400

Total = ₹600 × 5 + ₹400 = ₹3,400

If you produce 10 identical parts under the same setup, the effective per-part machining cost drops to ₹340, demonstrating how volume affects overall efficiency.

Sometimes the hourly rate does not capture the full project cost. Manufacturers and buyers should also consider:

- Inspection and testing fees: Especially for aerospace or defense components requiring CMM or hardness tests.

- Surface finishing or coating: Processes like anodizing, powder coating, or polishing add costs but enhance part longevity.

- Packaging and logistics: For export clients, durable packaging and customs handling can impact the final price.

- Rework or scrap loss: Due to human or programming errors, defective parts increase total cost allocation.

Understanding these hidden aspects ensures better cost transparency and negotiation leverage.

To make CNC machining in India more cost-effective, consider these actionable strategies:

1. Design optimization: Simplify geometries, avoid unnecessary tight tolerances, and minimize non-essential surface finishes.

2. Material selection: Choose machinable, readily available materials in India to reduce import dependency.

3. Batch production: Group parts with similar setups to distribute programming costs across a larger quantity.

4. Tolerances and standards: Keep tolerances realistic; excessive precision often drives up cutting time and inspection cost.

5. Supplier collaboration: Share CAD models early with suppliers—they often suggest modifications that reduce machining or tool-change cycles.

6. Local sourcing: Use Indian vendors for material and coating to cut transportation and import tariffs.

These efficiency steps not only reduce cost but also improve lead times and manufacturability.

Indian factories are integrating IoT-based CNC machines, robotic part loading/unloading, and process monitoring systems, which reduce downtime and improve productivity. Over time, these technologies may stabilize or lower the effective CNC machining cost per hour despite rising energy and labor prices.

Digital twins, adaptive feed controls, and AI-driven predictive maintenance are gradually improving operational efficiency across Indian machining industries. As these trends mature, buyers can expect more consistent pricing and faster turnaround times.

Environmentally conscious manufacturing practices, energy-efficient machine tools, and coolant recycling systems are becoming standard in new Indian workshops. Although initial investments are high, these efforts contribute to long-term cost savings and eco-friendly production.

When selecting a CNC machining partner, consider the following:

- Experience and Certification: Look for ISO 9001 or AS9100 accreditation.

- Equipment Capability: Confirm machine type (e.g., 5-axis, vertical/horizontal milling).

- Design Assistance: Suppliers that provide DFM (Design for Manufacturability) support can help refine your part design.

- Lead Time and Logistics: Reliable scheduling ensures on-time project completion.

- Quality Inspection Facilities: CMMs, hardness testers, and surface roughness gauges ensure accurate outputs.

Partnering with the right Indian machining supplier ensures not only cost savings but also long-term manufacturing consistency.

The CNC machining cost per hour in India is influenced by multiple factors, including machine type, design complexity, material, and region. Average prices typically fall between ₹400 and ₹1,200 ($5–$15), which is significantly lower than Western market rates while still ensuring global quality standards.

India's CNC machining sector continues to evolve rapidly, merging affordable labor with advanced automation. For global manufacturers, this presents an ideal opportunity to balance cost, quality, and production speed. By partnering with experienced Indian machining suppliers, businesses can achieve world-class precision while optimizing their overall production budget.

Contact us to get more information!

The hourly cost ranges from ₹400 to ₹1,200 ($5–$15) depending on machine type, part complexity, and location. Specialized machining like aerospace or medical applications can reach ₹2,000/hour ($25 USD).

Lower labor rates, competitive energy pricing, and government-supported manufacturing initiatives like “Make in India” make production more economical compared to Western nations.

Yes. Complex or tight-tolerance parts require more time, specialized tools, and precision equipment, increasing cost compared to simple designs.

Use machinable materials, simplify designs, combine operations in a single setup, and outsource to experienced Indian machine shops with efficient work handling.

Yes. Many Indian companies hold ISO 9001, ISO 13485, or AS9100 certifications and export CNC machined parts to the U.S., Europe, and Japan with global compliance and precision.

1. https://www.indiamart.com/

2. https://www.tradeindia.com/

3. https://www.machinedesign.com/

4. https://www.engineersgarage.com/

5. https://www.makeinindia.com/

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.