From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-29 Origin: Site

Content Menu

● Understanding Swiss-Type CNC Machining

● Why Switzerland Excels in CNC Machining

>> Global Certification and Trust

● Top Swiss-Type CNC Machining Manufacturers and Suppliers in Switzerland

>> 1. Tornos SA

>> 3. Esco SA

>> 4. BRM AG

● Applications of Swiss-Type CNC Machining

>> Watchmaking and Luxury Instruments

● Technological Trends Transforming Swiss CNC Machining

>> Real-Time Monitoring and Smart Factories

>> Environmental Sustainability

● Selecting the Right Swiss CNC Machining Partner

● The Global Impact of Swiss-Type CNC Technology

● Frequently Asked Questions (FAQ)

>> 1. What makes Swiss-type CNC machining different from conventional turning?

>> 2. Why are Swiss-type CNC machining manufacturers and suppliers highly regarded?

>> 3. Can Swiss-type CNC machining handle both prototypes and mass production?

>> 4. Which industries use Swiss-type CNC machining the most?

>> 5. Do Swiss suppliers provide OEM or ODM services for international clients?

Switzerland stands as a symbol of technological precision and craftsmanship recognized worldwide. Behind every high-performance industrial product—from luxury timepieces to aerospace components—lies a network of advanced Swiss-type CNC machining manufacturers and suppliers. These companies combine traditional Swiss attention to detail with modern automation, offering clients the ultimate in performance, consistency, and quality.

This article provides an in-depth overview of Switzerland's most trusted Swiss-type CNC machining manufacturers and suppliers, their expertise, applications, innovations, and the role they play in setting global standards for precision engineering.

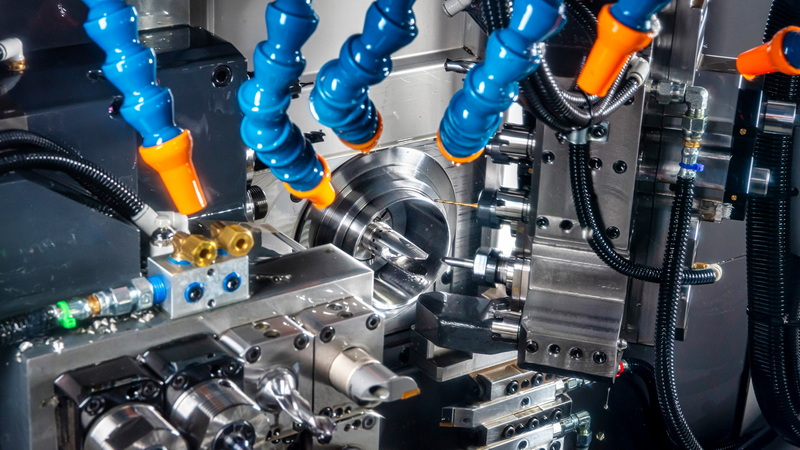

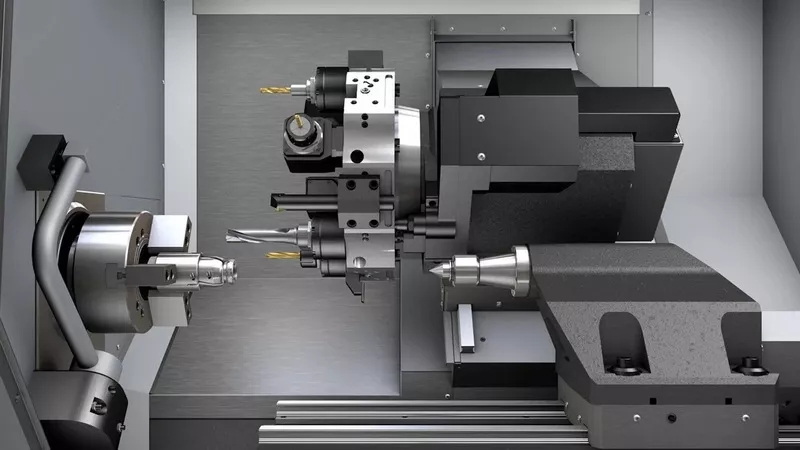

Swiss-type CNC machining, also called sliding headstock turning or Swiss automatic lathe machining, originated in the Swiss watchmaking industry. Engineers needed machines capable of producing microscopic, high-tolerance components consistently. Unlike conventional CNC lathes that fix the material in place, Swiss-type lathes feed the workpiece through a guide bushing near the cutting tool, maintaining perfect support and eliminating vibration.

- Extreme precision: Capable of maintaining tolerances within ±0.001 mm.

- Complex machining: Multi-axis operation enables turning, milling, drilling, and tapping in one setup.

- Material versatility: Suitable for stainless steel, titanium, brass, aluminum, and plastics.

- Efficiency: Reduces secondary operations, improving throughput for mass production.

- Automation: Ideal for 24/7 unattended machining with bar feeders and robotic systems.

Because of these qualities, modern Swiss-type CNC machining manufacturers and suppliers in Switzerland have expanded far beyond horology, now serving critical industries such as aerospace, medical devices, automotive, electronics, and precision instrumentation.

Switzerland's dominance in precision manufacturing rests on a foundation of skilled engineering, meticulous production culture, and strong investment in technology.

Swiss precision engineering has deep roots in the 19th century watchmaking tradition. That craftsmanship mindset has evolved into a modern industrial ecosystem where microns matter.

Switzerland's dual education system produces technicians trained in both design and manufacturing. Many engineers receive advanced CNC programming and mechatronics training, ensuring constant innovation on the workshop floor.

Swiss companies continually reinvest in R&D to enhance machining speed, reduce tool wear, and improve process reliability. Automation, robotics, and AI-driven monitoring are becoming standard in large-scale production.

Most Swiss-type CNC machining manufacturers and suppliers are ISO 9001, ISO 13485 (medical), or AS9100 (aerospace) certified. These accreditations reflect their commitment to quality, traceability, and process control—core requirements for global OEM and ODM projects.

For overseas clients, sourcing components from Swiss suppliers means peace of mind: unparalleled quality, on-time delivery, and full confidentiality in product development.

Below is a curated list of leading Swiss-type CNC machining manufacturers and suppliers that represent the best of Swiss mechanical precision and manufacturing reliability.

Location: Moutier, Switzerland

Expertise: Swiss-type lathes and precision turned components

Tornos SA pioneered the development of Swiss-type automatic lathes in 1898. Today, the company produces world-class CNC machines and also offers contract manufacturing for precision parts. Its products serve medical, electronics, and automotive industries. Tornos combines over a century of experience with Industry 4.0 smart factory solutions, helping manufacturers achieve cost-effective yet ultra-precise output.

Location: Steffisburg, Switzerland

Expertise: Grinding and precision finishing

While known for its grinding machines, Fritz Studer also provides Swiss-type CNC machining as part of its integrated manufacturing services. Its ability to combine fine turning, cylindrical grinding, and precision finishing under one roof provides unmatched part quality for demanding customers in aerospace, defense, and medical technology.

Location: Les Geneveys-sur-Coffrane, Switzerland

Expertise: Micro-machining for medical and watch industries

Esco SA is world-renowned for manufacturing micro-scale components through Swiss-type CNC machining. The company operates precision facilities capable of producing implants, bone screws, and other medical-grade parts with documentation traceability. Esco's automated loading and measuring systems guarantee both quality and speed for high-volume production.

Location: Biel/Bienne, Switzerland

Expertise: Micromechanical components and prototyping

BRM AG delivers high-complexity micro components using multi-axis Swiss-type lathes. They specialize in producing gears, shafts, and connectors for watches, optics, and semiconductors. Combining optical inspection and CMM verification, BRM maintains extremely tight tolerances even in miniature assemblies.

Location: Neuchâtel, Switzerland

Expertise: Aerospace and instrumentation CNC services

Serving clients in aerospace, electronics, and high-precision instruments, Precimet SA offers Swiss-type CNC turning, 5-axis milling, and mechanical assembly. They work with materials such as titanium and Inconel, and their EN 9100 certification underscores their reliability in aviation and defense manufacturing.

Location: Delémont, Switzerland

Expertise: Multi-process precision machining

Willemin-Macodel stands out for its innovation in combining precision milling and turning functions. Their modern Swiss-type systems produce intricate components for the watch, optics, and medical sectors. With in-house research and modular automation, Willemin-Macodel continues to push the limits of part complexity and production efficiency.

Location: Zurich, Switzerland

Expertise: Custom CNC machining and rapid prototyping

Mekanika AG merges precision Swiss processes with lean manufacturing principles. By integrating robotics and Swiss-type CNC machining, they deliver short lead times and scalable production. Their full-service solutions—from CAD design consultation to final inspection—are especially suited for OEM clients in Europe and North America.

Swiss-type machining is synonymous with accuracy and repeatability. Its range of applications covers multiple high-value industries.

Swiss-type machines produce bone screws, orthopedic implants, dental abutments, and surgical tools with flawless surface finishes. The biocompatibility of machined titanium and stainless steel components is crucial for patient safety, making Swiss suppliers trusted partners in healthcare manufacturing.

Modern vehicles rely on precision-engineered parts like fuel injectors, valves, and transmission shafts—all ideal for Swiss-type turning. Suppliers ensure long production runs with consistent dimensional accuracy, essential for automotive reliability and safety.

Swiss-type CNC machining enables the mass production of miniature connectors, sensor pins, and fiber-optic housings. Surface integrity and micro-deburring are vital for signal performance, and Swiss companies lead in these techniques.

Due to strict quality and material standards, aerospace parts—actuator shafts, nozzles, and pins—often depend on Swiss-type CNC machining. The machines' ability to handle superalloys like Inconel or titanium ensures durability under high stress and extreme temperatures.

Switzerland remains synonymous with luxury watchmaking. Micro gears, balance staffs, and escapement components are crafted with precision on Swiss-type lathes, maintaining the country's reputation for craftsmanship and heritage.

The Swiss-type CNC machining manufacturers and suppliers community continuously upgrades operations with the latest technologies to meet growing global demands.

Swiss factories increasingly adopt robotic systems for bar loading, part collection, and inspection. Automation not only cuts production time but also minimizes human error and improves safety.

IoT sensors and data analytics track spindle load, tool life, and part accuracy in real-time. This data-driven management boosts productivity and predictive maintenance efficiency.

Digital twin software allows engineers to simulate entire machining processes, predicting potential tool errors and optimizing cutting parameters before production begins.

Swiss manufacturers align with sustainability targets by using energy-efficient servo motors, recycling coolants, and reducing material waste. Some even source renewable energy for their CNC facilities.

Combining additive and subtractive processes, hybrid machining systems can manufacture complex geometries faster, benefiting R&D-heavy industries like aerospace and medical technology.

Choosing reliable Swiss-type CNC machining manufacturers and suppliers involves evaluating their technical capabilities, certifications, and customer support.

When sourcing a partner, consider the following factors:

1. Experience and Specialization – Does the supplier specialize in your component type or industry sector?

2. Equipment and Technology – Verify the use of advanced multi-axis lathes and automated systems.

3. Quality Management – A supplier certified under ISO or AS standards shows maturity in quality control.

4. Communication – Responsiveness and English-language documentation are key for international projects.

5. OEM/ODM Flexibility – Confirm capacity for custom production, prototype development, and intellectual property protection.

Many Swiss producers now maintain international collaborations, including partnerships with Chinese precision parts manufacturers that offer competitive pricing for volume production. This synergy enhances cost efficiency without compromising Swiss quality assurance.

Swiss CNC innovations have profoundly influenced manufacturing worldwide. From Europe and Asia to North America, Swiss machining technology has become a standard for accuracy.

- Technology Export: Swiss machine builders export cutting-edge lathes and technology to global factories.

- Skill Development: Swiss training institutions nurture engineers who later shape manufacturing practices abroad.

- OEM Collaboration: Swiss suppliers often partner with international firms, combining technical excellence with cost-effective supply networks.

This hybrid ecosystem ensures that Swiss-type CNC machining manufacturers and suppliers continue driving progress in precision technology on a global scale.

Switzerland's reputation for precision engineering is embodied in its Swiss-type CNC machining manufacturers and suppliers. From pioneers like Tornos SA to advanced micro-part specialists such as BRM AG and Esco SA, each company represents unrivaled dedication to detail and durability.

Global industries—from medical and aerospace to automotive and electronics—depend on Swiss expertise for mission-critical components that demand perfection. With advanced automation, innovation, and an unwavering focus on quality, Swiss-type CNC machining continues to drive the future of precision manufacturing on a global stage.

Contact us to get more information!

Swiss-type machines use a sliding headstock and guide bushing, supporting the workpiece close to the tool. This configuration prevents vibration and delivers exceptional accuracy for long, slender parts.

Because of their engineering precision, rigorous certifications, and continuous innovation. Swiss suppliers set industry benchmarks for reliability and micro-tolerance performance.

Yes. Swiss-type CNC lathes can be programmed for low-volume prototypes or fully automated for continuous production, maintaining consistent precision.

Medical devices, aerospace, electronics, watchmaking, and automotive sectors rely heavily on Swiss machining for high-accuracy components.

Absolutely. Many companies offer OEM/ODM services, confidentiality agreements, and multilingual support to help global customers integrate precision parts into their own branded products.

1. (https://www.tornos.com)

2. (https://www.studer.com)

3. (https://www.esco.ch)

4. (https://www.brm.swiss)

5. (https://www.precimet.ch)

6. (https://www.willemin-macodel.com)

7. (https://www.mekanika.ch)

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.