From idea to market-ready product, our NPI solutions make every stage easier, faster.

Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-29 Origin: Site

Content Menu

● Understanding Swiss-Type CNC Machining

● Why Thailand Has Become a Precision Machining Powerhouse

>> Strategic Benefits for Global Buyers

● Key Swiss-Type CNC Machining Manufacturers and Suppliers in Thailand

>> 2. Siam Precision Co., Ltd.

>> 3. Bangkok CNC Engineering Co., Ltd.

>> 4. Chonburi Precision Components Co., Ltd.

>> 5. Precision Thai Components (PTC)

>> 6. Delta Tech Engineering (Thailand) Co., Ltd.

● OEM and ODM Services by Thai CNC Companies

>> Common OEM/ODM Services Offered

● Collaboration Between Thai and Chinese Manufacturers

● Emerging Technologies in Thailand's CNC Industry

● Best Practices for Selecting a Supplier in Thailand

● Market Outlook and Future Opportunities

● FAQs About Swiss-Type CNC Machining Manufacturers and Suppliers in Thailand

>> Q1: What industries most commonly use Swiss-type CNC machining in Thailand?

>> Q2: How can I verify the reliability of a Thai CNC machining supplier?

>> Q3: Can Thai manufacturers support small batch production runs?

>> Q4: Are communication and project management smooth for overseas clients?

>> Q5: What are the lead times for typical CNC machined orders?

The global precision engineering sector has undergone rapid transformation during the last decade. With increasing demand for high-quality, small, and complex mechanical parts, Thailand has firmly established itself as a key manufacturing destination in Asia. The country is now recognized as a regional hub for Swiss-type CNC machining manufacturers and suppliers, providing precision OEM and ODM services to clients in automotive, aerospace, medical device, electronic, and defense industries.

This article takes an in-depth look at Thailand's evolving manufacturing landscape, highlighting leading suppliers, technological strengths, strategic advantages, and the emerging role of Thai precision engineering in the global market.

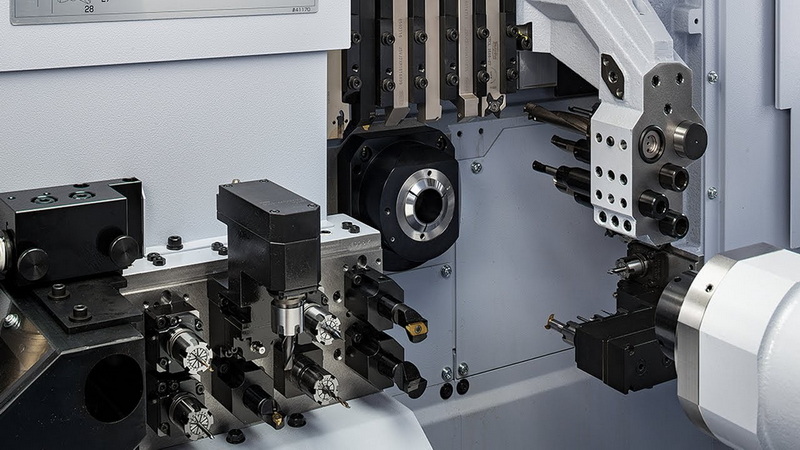

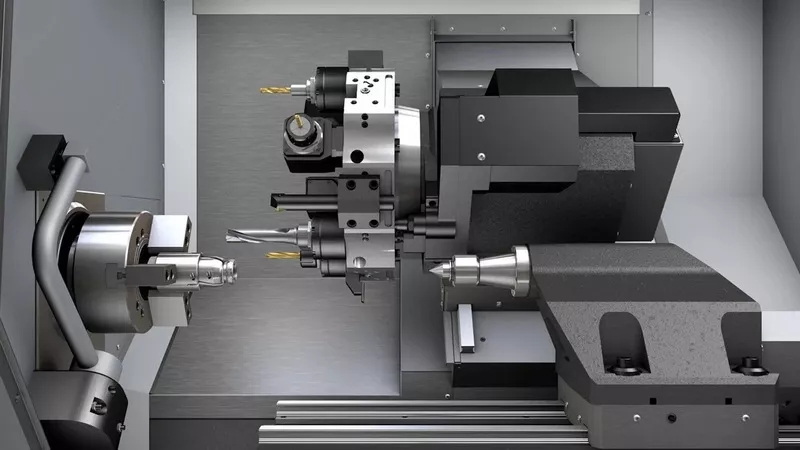

Swiss-type CNC machining, also known as Swiss turning or sliding headstock machining, was originally invented to produce miniature components for Swiss watches. Its mechanism allows the workpiece to move axially while the cutting tools perform simultaneous operations. This configuration ensures extreme dimensional accuracy and smooth surface finishes — key requirements in high-tech manufacturing today.

- Reduced vibration and deflection: Because the part is supported close to the cutting tool, precision remains consistent even during long, slender part machining.

- Multi-axis control: Many modern Swiss-type CNC machines operate with up to 10 axes, performing turning, milling, drilling, and tapping in one cycle.

- High material efficiency: The continuous bar-feeding system minimizes waste and ensures repeatable results for large-volume production.

- Flexible production: Ideal for both micro parts and mid-sized components across various batch sizes.

Materials commonly used by Swiss-type CNC machining manufacturers and suppliers in Thailand include titanium, aluminum, brass, copper, SUS stainless steel, and engineering plastics like PEEK and Delrin.

Thailand's manufacturing success is supported by decades of industrial infrastructure development and investment policies. With support from the Thailand Board of Investment (BOI), foreign companies receive tax incentives, streamlined import procedures, and access to specialized industrial clusters such as the Eastern Economic Corridor (EEC).

1. Cost Competitiveness: Thailand's production and labor costs are lower than Japan or Western countries, while maintaining similar standards of technical precision.

2. Skilled and Stable Workforce: The country's vocational and technical education programs create a consistent supply of machinists trained in Swiss-type CNC operations, CAD/CAM design, and digital machining systems.

3. Strong Supply Chain Ecosystem: Industrial hubs in Bangkok, Chonburi, and Rayong offer easy access to metal finishing, coating, and automotive part suppliers.

4. Global Connections: Thailand's ports, such as Laem Chabang, link directly to Asia, Europe, and North America for efficient export logistics.

5. Government and Private Partnerships: Investment programs aimed at smart manufacturing and Industry 4.0 transformation foster rapid technological adoption.

These advantages collectively make Thailand a reliable base for global OEM production in precision components.

Highlighted below are top-performing Swiss-type CNC machining manufacturers and suppliers offering consistent quality, compliance, and innovation for international clients.

Overview: Headquartered in Bangkok, Thai Takasago stands out for multi-axis CNC precision machining serving the automotive and electronics sectors.

Capabilities: 5–10 axis Swiss-type CNC turning, micro part assembly, and tool design.

Certifications: ISO 9001, IATF 16949.

Export Markets: Japan, Singapore, and Germany.

Notable Strength: Their quality control lab features Zeiss CMM and high-resolution surface analyzers for submicron accuracy.

Overview: A leading player in aerospace and medical precision components.

Capabilities: Swiss-type machining with in-house CAD/CAM programming and clean-room assembly.

Core Strength: Titanium, Inconel, and stainless steel machining for surgical devices.

Certifications: ISO 13485 and AS9100.

Key Advantage: Ability to prototype complex medical fittings within 48 hours.

Overview: This company integrates automation and robotics with precision CNC machining.

Equipment: Citizen and Tsugami models capable of multi-spindle simultaneous turning.

Industries Served: Automotive fuel injection, optical instrument parts, and semiconductor connectors.

OEM Services: In-house tool development, heat treatment, and real-time inspection systems.

Overview: Located in Thailand's Eastern Industrial hub, this company supports large-scale OEM production.

Capabilities: Micro-machining, Swiss-type turning, laser engraving, and anodizing.

Quality Standards: PPAP process approval and full FAI documentation.

Main Exports: Europe, the US, and South Korea.

Unique Capability: Offers mixed production batches for both prototypes and full-volume runs.

Overview: Provides integrated manufacturing solutions for high-precision mechanical components.

Capabilities: Swiss-type CNC machining, sub-assembly, polishing, and passivation.

Core Industries: Optics, electronics, communication, and healthcare system parts.

Certifications: ISO 9001 and RoHS compliance.

Advantages: Dedicated English-speaking project engineers for international buyers.

Overview: A rapidly growing precision parts supplier offering turnkey design-to-manufacturing solutions.

Capabilities: CNC Swiss-type machining, precision milling, grinding, and EDM services.

Industries: Telecommunications, robotics, and aerospace.

Competitive Edge: Integration of AI-enabled inspection cameras for zero-defect control.

R&D Strength: Collaborates with local universities on process optimization and new alloy research.

Most Swiss-type CNC machining manufacturers and suppliers in Thailand have transitioned beyond part production into full-service OEM and ODM partnerships. This includes design assistance, prototyping, and final assembly.

- Technical design development from customer drawings or 3D models.

- Rapid prototyping and sample validation before production.

- Precision surface treatments such as plating, coating, and polishing.

- Customized packaging and global logistics support.

- Spare parts management and after-sales support for long-term clients.

This full-spectrum service model makes Thai suppliers competitive alternatives to Japanese or Taiwanese precision manufacturers in global sourcing networks.

Partnership between Thai and Chinese OEM suppliers is growing swiftly. Many Chinese companies supply raw materials, semi-finished blanks, or subassemblies to Thai machining workshops. This collaboration lowers cost, increases capacity, and strengthens regional specialization.

For instance, a Chinese OEM providing aluminum forging blanks may ship semi-processed components to Thai factories, where Swiss-type CNC machining achieves the final micrometer-level finishing. This hybrid supply chain balances cost efficiency with unmatched quality—an ideal model for international brands needing precision without excessive logistics complexity.

Thailand's journey toward smart manufacturing is transforming how precision machining operates. Forward-looking companies are investing in digital technologies to improve productivity, consistency, and transparency.

- Automation: Integration of cobots (collaborative robots) and auto-feeding systems to reduce downtime.

- Data-driven maintenance: Implementation of IIoT sensors to predict machine tool wear and schedule timely maintenance.

- 5G-enabled production: High-speed connectivity allows remote machine monitoring and data sharing with international clients in real time.

- Green machining: More facilities adopt coolant recycling, eco-friendly materials, and renewable energy sources.

- Traceability systems: Barcodes and digital dashboards are now standard in high-volume production lines.

These innovations help Thailand's Swiss-type CNC machining manufacturers and suppliers maintain global competitiveness by aligning with sustainability and digitalization trends.

When sourcing precision components, buyers should evaluate both technical and operational aspects to ensure smooth project execution. Below are recommended guidelines:

1. Audit Production Equipment: Verify if suppliers operate with modern machines such as Star, Citizen, Tsugami, or Tornos systems.

2. Confirm Material Expertise: Check track records with specialty materials (titanium, SUS316, etc.).

3. Request Quality Records: Ensure suppliers maintain traceable inspection documents and SPC data.

4. Understand Capacity Limits: Identify batch size capability and machinery count to plan scalable production.

5. Visit the Facility: A direct factory visit helps assess cleanliness, organization, and workflow.

6. Negotiate Terms Clearly: Establish inspection standards, lead time, and payment milestones upfront.

Choosing a professional and experienced Swiss-type CNC machining manufacturer and supplier in Thailand builds long-term reliability and consistent performance for your OEM projects.

Thailand continues to strengthen its position as a preferred destination for precision engineering. Over the next decade, expansions in sectors like electric vehicles (EVs), smart electronics, and medical technology will further increase demand for Swiss-type CNC machining manufacturers and suppliers.

Investors and buyers can expect:

- An uptick in R&D investments in automation and micro-machining.

- A steady rise in BOI-approved foreign direct investments.

- Stronger compliance with ESG (Environmental, Social, Governance) frameworks.

- Closer collaboration between ASEAN nations to build a unified precision manufacturing corridor.

With a balance of quality, cost, and innovation, Thailand is poised to remain one of Asia's premier CNC machining centers.

Thailand's precision manufacturing sector has evolved from basic metalworking to world-class Swiss-type CNC machining operations driven by modern technology, quality assurance, and OEM service integration. Its combination of skilled labor, cost efficiency, and strategic regional partnerships continues to attract global buyers searching for reliable precision component suppliers.

For international brands, distributors, and manufacturers, Thailand offers a balanced, sustainable, and technologically advanced environment for Swiss-type CNC machining manufacturers and suppliers. As digital transformation deepens and collaborative supply chain innovations grow, Thailand's precision industry is well on its way to becoming an essential pillar of global engineering excellence.

Contact us to get more information!

A1: The main industries include automotive, aerospace, medical devices, watchmaking, and electronics, where intricate components with high accuracy are required.

A2: Check certifications (ISO 9001, IATF 16949, AS9100), request sample parts, and ask for references from existing clients.

A3: Yes. Many Swiss-type CNC machining manufacturers and suppliers in Thailand offer flexible volumes, including prototypes and small series production.

A4: Most manufacturers employ English-speaking engineers and export managers to ensure clear, timely communication throughout the project lifecycle.

A5: Depending on part complexity and volume, standard delivery ranges from 3–6 weeks, with expedited prototypes possible within one week.

1. (https://www.boi.go.th)

2. (https://www.fti.or.th)

3. (https://www.eec.gov.th)

4. (https://cmj.citizen.co.jp)

5. (https://www.tsugami.co.jp)

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.