From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-30 Origin: Site

Content Menu

● Understanding Tooling Marks in CNC Machining

● Assessing the Severity of Machining Marks

>> Sanding and Surface Preparation

>> Edge Re-Machining or Refinement

● Chemical Cleaning and Finishing Techniques

● How to Prevent Tooling Marks During CNC Machining

● Maintenance and Storage After Cleaning

● Environmental and Safety Considerations

● Applications Requiring High-Precision Polished Plexi Edges

● FAQ

>> 1. What causes tooling marks on plexi during CNC machining?

>> 2. Can flame polishing remove all machining marks?

>> 3. How does vapor polishing differ from buffing?

>> 4. What are the safest cleaning solvents for plexiglass?

>> 5. How can I reduce tooling marks in future CNC machining runs?

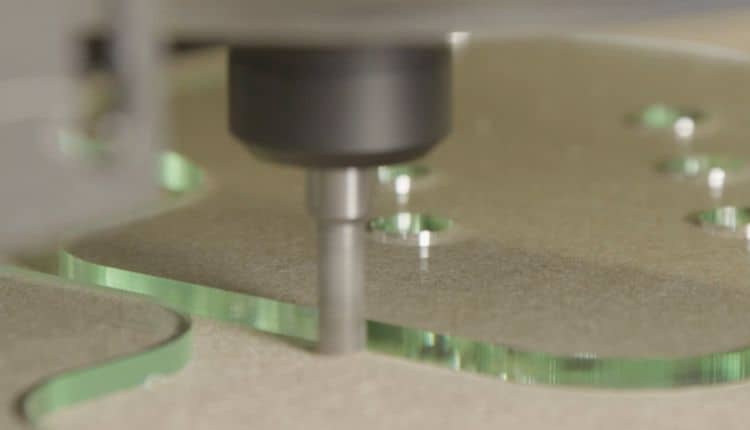

CNC machining is the preferred manufacturing method for creating precise and high-quality acrylic (plexiglass) parts in industries ranging from signage and architecture to optical components and display fabrication. However, even the best CNC machining setups can leave slight tooling marks or cloudy edges, especially on transparent materials like plexiglass.

These machining marks — microscopic grooves, ridges, or faint scratches — can reduce the optical clarity of the finished product. Fortunately, with the right post-processing techniques and good machining practices, it's entirely possible to clean CNC machining tooling marks and restore the clear, glossy edge that plexi components are known for.

This comprehensive guide explores both mechanical and chemical cleaning techniques, preventive strategies, and maintenance tips to help you achieve flawless plexiglass edges after CNC machining.

Tooling marks on plexi edges result from friction between the cutting tool and the acrylic surface during CNC machining. As the tool rotates, slight imperfections in speed, feed rate, tool geometry, or chip evacuation can lead to score lines, micro-tears, or milky discoloration.

Common causes of tooling marks include:

- Improper cutting parameters (feed rate too fast or spindle speed too slow).

- Worn or incorrect cutter tool geometry, especially when using HSS instead of carbide or diamond tools.

- Inadequate removal of heat and chips, leading to localized melting of the plexiglass surface.

- Re-cutting of plastic shavings, which may smear across the edges instead of creating clean chips.

- Improper step-over in finishing passes, leaving visible toolpath lines.

In short, tooling marks are the direct result of cutting conditions and material softness. Acrylic, due to its lower melting point, is particularly prone to heat-induced smearing — which means precision and proper parameter settings during CNC machining are crucial.

Before you begin cleaning or polishing plexiglass edges, inspect the component's condition under bright lighting. You can determine the best cleaning method by evaluating:

- Depth of surface defects – Are they shallow shadow marks or deep score lines?

- Edge geometry – Flat, beveled, curved, or stepped edges may require different polishing techniques.

- Optical clarity – Determine whether the cloudiness is from surface abrasions or deeper material deformation.

- Heat damage – Look for small waves or ripples indicating prior overheating during CNC machining.

Shallow marks can be easily buffed away, while deeper damage may require sanding and polishing or even flame polishing for complete restoration.

Sanding is a safe and precise approach for removing CNC machining tooling marks from plexi edges. It allows for control over surface uniformity and prevents excessive material removal.

To achieve professional-quality results:

1. Begin with fine-grit sandpaper (400–600 grit) to remove the initial tool marks. Sand lightly to avoid generating heat.

2. Progressively move to higher grits – 800, 1000, 1500, and up to 2000 – ensuring that each finer stage eliminates scratches from the previous one.

3. Wet sanding is highly recommended. Water acts as both a lubricant and coolant, reducing friction while flushing away fine acrylic particles.

4. After completing the sanding process, dry and inspect the edge using a flashlight. The marks should now appear significantly reduced or invisible under light.

Always sand in the same direction for flat edges, or follow the curvature if dealing with rounded pieces. This consistency ensures uniformity across the plexi surface.

Once sanding is complete, move to the polishing process to restore full transparency:

- Use a soft cotton or microfiber buffing wheel attached to a low-speed rotary tool or bench polisher.

- Apply a specialized acrylic polishing compound — aluminum oxide or diamond paste works well.

- Buff the edges gently in small circular motions until the surface becomes smooth and glossy.

- Avoid prolonged contact in one spot to prevent heat buildup and possible surface warping.

Buffing not only eliminates residual sanding scratches but also enhances the optical appeal, making the edges look clear and professional after CNC machining.

Flame polishing is one of the fastest methods for achieving a glass-like finish on CNC-machined plexiglass. This technique uses a high-temperature flame to briefly melt the outer layer of the acrylic, allowing it to self-level and remove fine tooling marks.

To safely perform flame polishing:

1. Use a hydrogen-oxygen or propane torch with a controlled, fine flame.

2. Keep the nozzle 2–3 centimeters from the surface and move continuously along the edge.

3. Do not linger in one area — excessive heat can bubble or distort the acrylic.

4. Allow the piece to cool naturally in ambient air before touching or cleaning it further.

When performed correctly, flame polishing provides mirror-like clarity in seconds. It is particularly useful for display components, signage edges, and optical windows produced through CNC machining.

In cases where tooling marks are too deep for polishing or sanding, the best method is to re-machine the affected edge using a fine finishing pass.

- Use a diamond-coated or carbide bit designed for acrylic machining.

- Reduce the feed rate and step-over to minimize contact pressure.

- Increase spindle RPM slightly to achieve a melt-free shearing cut.

This light trimming removes a thin outer layer and produces a smoother edge requiring minimal further polishing. Many manufacturers integrate this final pass directly into their CNC machining programs to reduce manual finishing time.

Vapor polishing is ideal for restoring transparency on CNC-machined plexiglass edges. It involves exposing the surface to solvent vapors — most commonly dichloromethane or acetone vapors — which melt the outer micro-layer to form a glass-smooth finish.

Procedure:

1. Place the part in a sealed vapor chamber.

2. Expose it briefly to solvent vapors until the surface begins to shine.

3. Remove and allow to cool in a dust-free environment for several hours.

This process refines even the smallest tooling marks and gives the plexiglass a near-optical grade clarity. However, safety precautions are critical since solvent vapors can be harmful without adequate ventilation or fume extraction systems.

For light surface dullness after CNC machining, wiping with solvent-dampened pads can offer a cleaner, brighter appearance.

- Use only solvents designed for acrylic, such as isopropyl alcohol or mild acrylic cleaners.

- Avoid harsh chemicals like toluene or xylene, which can cause surface crazing.

- Always wear gloves and work in a clean, lint-free environment.

This method should only be used for minor corrections, as excessive solvent exposure can lead to whitening or softening of the plexi surface.

The best practice is to prevent tooling marks from forming in the first place. Implementing proper CNC machining strategies not only saves finishing time but also extends the lifespan of your cutting tools.

Key recommendations include:

- Use high-quality, sharp cutters designed for acrylic, preferably single-flute or O-flute bits.

- Optimize spindle speed (around 18,000–22,000 RPM) and feed rate to balance heat and chip load.

- Avoid recutting chips by maintaining an effective vacuum or air blast system.

- Add coolant misting or compressed air to disperse heat during machining passes.

- Include a final finishing pass with small step-over and minimal depth to reduce residual marks.

- Secure the workpiece properly to prevent micro-vibration, which can result in uneven cut lines.

Taking time to configure correct machining parameters helps achieve cleaner edges straight from the CNC machine, reducing the need for heavy post-polishing.

Once the CNC machining tooling marks are completely removed, proper care will help maintain the polished look:

- Handle plexiglass parts with soft gloves to avoid fingerprint staining.

- Use non-abrasive cleaners for dust and smudge removal.

- Store the components horizontally with protective film between layers.

- Consider applying a protective acrylic sealer or anti-scratch coating for longevity.

- Keep finished parts away from extreme temperatures or direct UV exposure, which could cause yellowing over time.

Following these steps ensures your CNC-machined plexiglass remains pristine and professional for presentation, assembly, or end-customer delivery.

Mistakes during cleaning and polishing often lead to additional damage rather than improvement. Avoid the following:

- Using sandpaper that is too coarse, which creates visible scratches instead of removing existing ones.

- Applying excess pressure during buffing, which generates excessive heat.

- Using uncontrolled flame polishing, causing melting or discoloration.

- Mixing chemical cleaning solutions without understanding solvent compatibility with acrylic.

- Ignoring safety practices such as ventilation and protective gear when using volatile solvents.

Avoiding these common pitfalls ensures smoother edges and prevents rework, saving both material and labor costs.

CNC machining and polishing processes can create microplastic dust and solvent residues. To practice environmental responsibility:

- Use dust extraction systems during sanding and machining.

- Dispose of polishing residues in accordance with local environmental regulations.

- Choose water-based or low-VOC cleaners wherever possible.

Safety comes first when heat, solvents, and fine dust are involved. Always wear protective eyewear, gloves, and a respirator when performing these finishing processes.

Clean, transparent edges are critical in various industries where visual appeal and accuracy are both essential:

- Architectural lighting panels and displays

- Medical device housings and laboratory enclosures

- Optical components, lenses, and covers

- Advertising signs, exhibits, and retail fixtures

- Automotive and aerospace interior panels

In each of these applications, proper post-machining treatment ensures that the finished component meets functional and aesthetic requirements.

Cleaning CNC machining tooling marks from plexi edges involves understanding both the machining process and the material's physical response to sanding, polishing, and chemical agents. Whether you use progressive sanding, flame polishing, solvent vapors, or finishing passes, each method can restore clarity and precision to the edges of your acrylic components.

However, the most effective solution combines prevention during CNC machining with careful post-processing. With optimized cutting parameters, correct tool selection, and consistent maintenance practices, you can achieve crystal-clear plexiglass edges that reflect true CNC machining excellence.

Contact us to get more information!

Tooling marks are caused by poor cutting conditions — such as dull tools, incorrect feed rates, or insufficient cooling. Acrylic's low melting point makes it susceptible to surface smearing if heat is not managed properly during CNC machining.

Flame polishing works well for superficial marks but cannot fix deep cuts or gouges. It's best used after fine sanding to achieve a high-gloss result on CNC-machined surfaces.

Vapor polishing melts the top micro-layer of acrylic through solvent exposure, providing a perfectly smooth surface. Buffing mechanically abrades the surface using compounds — both methods can complement each other in post-machining finishing.

Mild agents like isopropyl alcohol or specialized acrylic cleaners are safest. Avoid strong chemical solvents such as acetone in open environments unless handled under vapor-controlled equipment.

Perform regular maintenance on tooling, use updated machining software with smoothing algorithms, adjust spindle speeds, and add finishing passes at reduced depth. This proactive strategy ensures consistent results with minimal post-finishing.

1. https://www.acrylitepolishing.com

2. https://www.cnccookbook.com

3. https://www.plexiglas.com

4. https://www.makeitfrom.com/materials/acrylic

5. https://www.instructables.com/CNC-Acrylic-polishing

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.