From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-27 Origin: Site

Content Menu

● Understanding Plastic CNC Machining

● Key Factors Influencing Plastic CNC Machining Cost

>> 2. Part Geometry and Design Complexity

>> 3. Tolerances and Precision Requirements

>> 4. Quantity and Production Volume

>> 5. Machining Time and Setup Cost

>> 6. Finishing and Post-Processing

● Average Cost Breakdown Example

● CNC Machining Cost Compared with 3D Printing and Injection Molding

● Ways to Reduce Plastic CNC Machining Costs

● Choosing the Right CNC Machining Partner

● FAQ About Plastic CNC Machining

>> 1. What is the average hourly rate for CNC machining plastic parts?

>> 2. Which plastic is easiest and cheapest to machine?

>> 3. How accurate is plastic CNC machining?

>> 4. How can I lower the cost of CNC machined plastic parts?

>> 5. What industries commonly use plastic CNC machining?

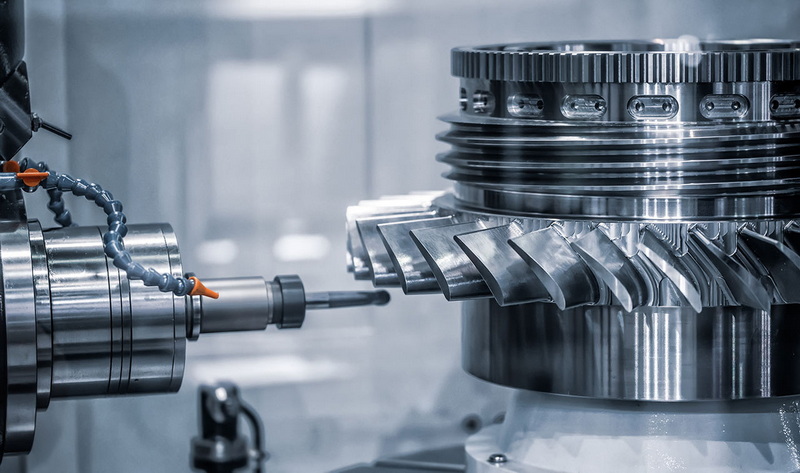

CNC machining is one of the most reliable and precise methods for manufacturing plastic components, widely used across automotive, medical, aerospace, and consumer industries. It allows engineers to create prototypes and end-use parts directly from solid plastic blocks with excellent tolerances and repeatability.

However, when planning a project, one of the most frequent questions customers ask is: how much does plastic CNC machining cost?

To answer this, it's necessary to understand the cost structure behind CNC machining — including materials, machine setup, geometry complexity, tolerances, and finishing. This article offers a deep dive into all these factors and provides practical strategies to optimize your budget while maintaining product quality.

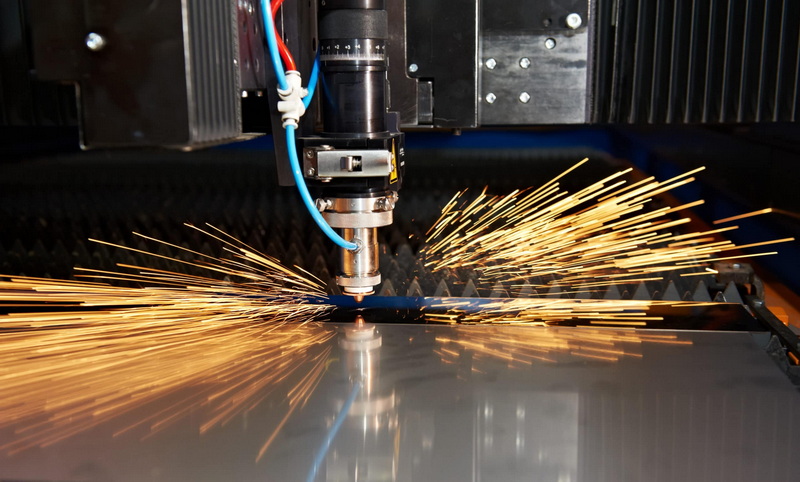

Plastic CNC machining is a subtractive manufacturing process that removes material from a solid block (or rod) using computer-controlled tools. This differs from additive processes like 3D printing or molding-based processes such as injection molding. CNC machines use precise codes (G-code) to guide tools like mills or lathes, ensuring consistent dimensions and surface finishes.

The key advantages of CNC machining for plastics include:

- Extremely high dimensional accuracy and repeatability.

- Fast production of prototypes and low-volume parts without expensive molds.

- Broad compatibility with engineering plastics like ABS, POM, PEEK, or Nylon.

- Ability to produce complex geometries that 3D printing sometimes cannot handle.

- Customization flexibility across small or batch runs.

Plastic CNC machining is especially useful for applications requiring strong mechanical properties and tight tolerances — for example, structural prototypes, insulating housings, or custom enclosures.

The total cost of CNC machining plastic parts is determined by multiple interacting factors. Knowing these allows you to make informed trade-offs between precision, cost, and function.

Material choice directly affects machine performance, tool wear, and part durability. Some plastics are easy to machine, while others require slow feed rates and more frequent tool changes.

Common plastics used in CNC machining include:

- ABS (Acrylonitrile Butadiene Styrene): Low-cost, versatile, and easy to machine; ideal for prototypes and enclosures.

- Nylon (PA6, PA66): Tough and lightweight; slightly higher cost due to moisture absorption control.

- Polycarbonate (PC): Excellent impact resistance, slightly harder to machine due to higher toughness.

- Delrin (POM): High stiffness and stability; good for gears, bushings, and precision parts.

- PEEK (Polyether Ether Ketone): High-performance engineering plastic for aerospace, medical, and thermal resistance applications — premium cost.

Although raw material prices vary ($2–$50 per pound), total cost is determined more by machine time and tool wear than by the material itself.

The geometry of the part significantly influences CNC machining cost. Straightforward designs like simple spacers, blocks, or disks are faster and cheaper to machine. By contrast, parts with curved surfaces, deep pockets, thin walls, or compound angles need multiple setups and longer machining cycles.

For instance, a single-sided milling part might cost $20, while a complex multi-axis part with intricate internal cavities could exceed $200. Using 5-axis CNC machining allows production of such parts in one setup but with higher hourly rates due to machine sophistication.

Simplifying the model and avoiding unnecessary details is a key way to cut costs while preserving essential functionality.

CNC machining's biggest advantage is dimensional precision. However, the tighter the tolerance, the higher the cost. Standard tolerances of ±0.1 mm are sufficient for most plastic prototypes, but high-precision instruments may demand ±0.01 mm accuracy or better.

To achieve these tolerances, machinists reduce cutting speeds and make multiple finishing passes. They may also use more expensive measuring instruments or temperature control — increasing both setup and runtime. Unless your application absolutely requires ultra-precise dimensions, keeping tolerances moderate can reduce up to 30% of machining costs.

Because CNC machining doesn't rely on molds, it is ideal for small-batch or custom parts production. The setup and programming costs are distributed across all units, so per-piece cost decreases as quantity increases.

Typical cost behavior by volume:

| Quantity | Cost per Unit | Notes |

|---|---|---|

| 1–5 pcs | Highest | Best for prototypes |

| 10–50 pcs | Moderate | Economical for small runs |

| 100–500 pcs | Lower | Setup cost spread out |

| 1000+ pcs | Usually better with injection molding |

If you expect repeated production, discuss with your supplier about fixture reuse and CAM optimization — it can significantly reduce repeat setup times.

Setup time includes preparing raw material, fixturing, selecting tools, and programming CAM software. A complex job may take several hours of setup before the machine even starts cutting.

Machining time, on the other hand, is the actual cutting duration. This depends on spindle speed, feed rate, toolpath strategy, and part geometry. The longer the machine runs, the higher the cost.

Typical hourly rates:

- 3-axis milling: $35–$80/hour

- 5-axis complex machining: $80–$150/hour

- Turning (lathe work): $30–$70/hour

If a part requires multiple sides to be machined, adding fixture rotations or secondary setups further increases the total cost.

After machining, plastic parts often need finishing steps to improve aesthetics or performance. Post-processing is an often-overlooked cost driver.

Common finishing steps for plastic CNC parts include:

- Deburring: Removes sharp edges and burrs created during cutting.

- Sanding and polishing: Achieves smooth or optical surfaces for display parts.

- Vapor polishing (for PC): Produces transparent, glass-like finishes.

- Anodizing (for metal inserts) or painting: Enhances appearance and corrosion resistance.

- Annealing: Relieves internal stress in high-performance plastics like PEEK.

Depending on approach, finishing can add an extra $5 to $50 per part.

CNC machining costs vary globally due to wage, overhead, and power expenses.

| Region | Price Range | Typical Lead Time |

|---|---|---|

| China & Southeast Asia | $25–$60/hour | 3–7 days |

| Eastern Europe | $40–$80/hour | 5–10 days |

| Western Europe & USA | $70–$150/hour | 5–12 days |

While sourcing overseas can reduce unit costs, ensure that suppliers maintain quality inspection standards and use reliable shipping methods to offset potential delays.

Here's an example cost breakdown for producing a small CNC-machined ABS plastic housing:

| Cost Element | Description | Estimated Cost |

|---|---|---|

| Raw Material | ABS block 100×100×50 mm | $5.00 |

| Setup & Programming | CNC operator setup (1 hour) | $60.00 |

| Machining Time | 1.5 hours @ $45/hr | $67.50 |

| Finishing & Inspection | Deburring, sanding | $10.00 |

| Total Estimated Cost (per unit) | $142.50 |

For a batch of 10 units, setup cost spreads out to $6 per part, reducing the total to roughly $90 per piece — a significant saving.

When considering plastic part manufacturing, it's useful to compare CNC machining with alternative technologies.

| Process | Setup Cost | Volume Suitability | Material Range | Surface Finish | Tolerance | Typical Lead Time |

|---|---|---|---|---|---|---|

| CNC Machining | Moderate | Low–Medium | Broad (ABS, POM, PEEK, etc.) | Excellent | ±0.01 mm | 3–7 days |

| 3D Printing | Low | Prototyping | Limited (Resins, PLA, Nylon) | Moderate | ±0.2 mm | 1–3 days |

| Injection Molding | High | High-volume | Very broad | Excellent | ±0.05 mm | 2–5 weeks |

- CNC machining offers the best balance between strength, surface quality, and material choice for low to mid-range volumes.

- 3D printing is cheaper for rapid prototypes but weaker in mechanical properties and tolerance.

- Injection molding is the most cost-effective for large-scale production but involves significant upfront tooling cost.

Thus, plastic CNC machining fills the gap between quick prototypes and mass production.

Reducing CNC machining cost doesn't mean compromising quality. Here are key methods professionals use:

1. Optimize your design. Minimize deep cavities, undercuts, and sharp internal corners.

2. Use machinable plastics. Choose Delrin or ABS unless high-performance materials like PEEK are required.

3. Apply reasonable tolerances. Avoid unnecessary micro-tolerances.

4. Increase order quantities. Reduce the cost per unit by distributing setup overhead.

5. Request design feedback. A professional machining partner may suggest geometry or material improvements.

6. Combine parts. If possible, design fewer joined components to reduce assembly time.

7. Simplify finishing. Choose functional over aesthetic surfaces unless required for product display.

Through effective design-for-manufacturing (DFM) collaboration, companies can save up to 40% of total machining cost in some projects.

Selecting a reliable CNC machining supplier is crucial to achieve both quality and cost efficiency. When evaluating partners:

- Experience matters. Ensure they specialize in plastic machining, as tooling and cutting techniques differ from metals.

- Check equipment list. Reputable suppliers operate HAAS, DMG MORI, or Fanuc machines for accurate performance.

- Review quality systems. ISO 9001 or AS9100 certification indicates process consistency.

- Inspect samples or customer references. A trusted partner provides transparency.

- Communication and support. Good suppliers offer DFM consultations and responsive updates during production.

A well-selected partner not only minimizes errors but also helps optimize tool paths and tool life, further reducing overall cost.

The cost of plastic CNC machining depends on a range of factors — including material type, complexity, tolerances, finishing, and production location. For most small to medium projects, costs typically fall between $10 and $250 per piece, depending on requirements and quantity.

To achieve the best cost-performance ratio, balance your design objectives with feasible manufacturing strategies. Use machinable plastics, optimize geometry, and cooperate closely with CNC machining experts. With thoughtful planning, CNC machining can deliver both precision and affordability for high-quality plastic parts.

Contact us to get more information!

Most rates fall between $35 and $120 per hour depending on machine type, material, and region. Five-axis operations or tight tolerances may increase hourly rates.

ABS and Delrin (POM) are the easiest and most economical plastics to machine because of their good chip formation and dimensional stability.

Standard tolerance is ±0.1 mm, but advanced setups can achieve ±0.01 mm precision for critical functional components.

Simplify geometries, choose standard tolerances, use affordable materials, and increase order volume to distribute setup costs efficiently.

Aerospace, automotive, medical, consumer electronics, and industrial automation sectors all rely on plastic CNC machining for prototypes and end-use parts.

1. (https://www.xometry.com/resources/cnc-machining/)

2. (https://www.protolabs.com/resources/design-tips/plastic-cnc-machining/)

3. (https://www.hubs.com/knowledge-base/cnc-machining-cost/)

4. (https://www.fictiv.com/articles/cnc-machining-costs-and-factors)

5. (https://machiningdesign.com/plastic-cnc-machining-guide/)

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.