From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-29 Origin: Site

Content Menu

● Understanding Swiss-type CNC Machining

● The Rise of CNC Machining in Afghanistan

● Advantages of Swiss-type CNC Machining

>> 2. Simultaneous Multi-Axis Operation

>> 3. Stability for Long Workpieces

>> 4. Impeccable Surface Finish

● Leading CNC Machining Companies in Afghanistan

>> Kabul Precision Engineering Co.

>> Afghan Aero Manufacturing Group

>> Jalalabad Tool & Micro Parts Co.

>> Panjshir Engineering Solutions

● The Role of Chinese OEM Partnerships

● Material Capabilities and Production Techniques

● Quality Assurance and Certification

● Applications of Swiss-type CNC Machining in Afghanistan

● Technological Advancements in Afghan Machining

● How to Choose a Reliable Swiss-type CNC Machining Supplier

● FAQs about Swiss-type CNC Machining in Afghanistan

>> Q1: What industries in Afghanistan use Swiss-type CNC machining?

>> Q2: Are there certified Swiss-type CNC machining manufacturers in Afghanistan?

>> Q3: How can overseas buyers collaborate with Afghan machining companies?

>> Q4: What is the lead time for typical CNC machining projects in Afghanistan?

>> Q5: Why should businesses consider sourcing from Afghanistan?

The global precision manufacturing sector is evolving rapidly, with an increasing focus on micro-accuracy, material reliability, and cost efficiency. Among the most advanced technologies supporting this shift is Swiss-type CNC machining, which has long been associated with the production of highly precise, small, and complex components. In Afghanistan, this technology is gradually taking root through partnerships with international engineering firms and investment from overseas OEM providers.

This article explores the development of Swiss-type CNC machining manufacturers and suppliers in Afghanistan, their capabilities, materials, applications, and how they cooperate with global buyers—especially Chinese OEM suppliers—to shape the country's precision machining future.

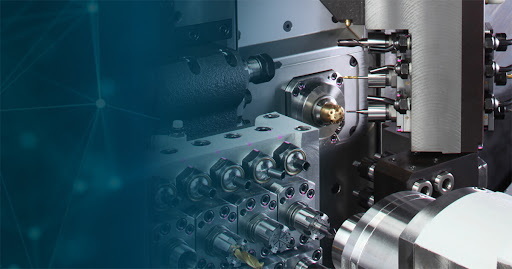

Swiss-type CNC machining is a specialized turning process that originated from the Swiss watchmaking industry. It is designed for manufacturing intricate components with extremely tight tolerances. Unlike conventional lathes, Swiss-type machines feature a sliding headstock and guide bushing that allow the bar stock to move axially during machining. This structure ensures high stiffness, minimal vibration, and outstanding accuracy even for long, slender workpieces.

High-end Swiss-type CNC machines can operate on 7 to 12 axes simultaneously, performing multiple cutting, drilling, or milling actions in one cycle. As a result, they significantly reduce setup time and secondary processing needs.

Industries relying on Swiss-type CNC machining include:

- Aerospace and aviation components

- Medical instruments and surgical implants

- Automotive transmission and fuel systems

- Electronics connectors and sensors

- Watchmaking, defense, and precision tooling

The versatility of this technology makes Swiss-type CNC machining manufacturers and suppliers essential partners for companies seeking perfection in micro-mechanics.

Afghanistan's industrial journey has been shaped by reconstruction, foreign aid, and private entrepreneurship. Historically, the country's economy focused on agriculture, mining, and textiles. However, the growing need for high-tech infrastructure and defense equipment has opened new opportunities for local precision machining.

Cities such as Kabul, Herat, and Jalalabad have become focal points for small machining workshops, where local engineers are increasingly adopting Swiss-type CNC machining technologies. Many Afghan enterprises now collaborate with Chinese, Turkish, and Indian suppliers to import advanced lathes, cutting tools, and CAD/CAM software systems.

These collaborations have given rise to a new generation of Swiss-type CNC machining manufacturers and suppliers who can handle customized production, OEM orders, and small-batch precision projects. Although still at an early stage, Afghanistan's machining sector exhibits strong potential for integration into global supply chains—especially for cost-effective OEM and replacement parts.

The benefits of Swiss-type CNC machining go beyond precision. They include operational efficiency, consistent quality, and material versatility. Below are the key reasons why industries globally—and now in Afghanistan—are embracing this technology:

Swiss-type CNC machining can achieve tolerances of less than ±2 microns. This level of precision ensures every component fits perfectly into complex assemblies such as medical implants or optical devices.

Multiple tools operate concurrently, enabling the machining of intricate geometries in one setup. This dramatically improves throughput and reduces cycle time.

By supporting the material close to the cutting zone through a guide bushing, Swiss-type lathes can machine long, thin parts with minimal deflection—ideal for producing shafts, rods, pins, and valves.

The controlled tool pressure and cutting speed produce smooth surfaces, minimizing polishing and finishing needs.

Once programmed, a Swiss-type CNC machine can run unattended, lowering labor costs and ensuring consistent accuracy for volume production.

Such advantages make Swiss-type CNC machining manufacturers and suppliers indispensable partners in modern industrial production.

Although Afghanistan's precision engineering industry is still maturing, several emerging companies are building a solid reputation in CNC manufacturing and prototype development.

Located in the suburban industrial zone of Kabul, the company operates CNC lathes, milling centers, and recently added Swiss-type automatic lathes. With technical guidance from Chinese engineers, they supply high-precision bushings, miniature shafts, and electronic housings for export.

Herat has become a center for light manufacturing and mechanical repair. This company focuses on hydraulic fittings, defense connectors, and custom metal parts. The adoption of Swiss-type CNC systems has allowed it to expand into the precision automotive and oil pipeline sectors.

This group supports Afghanistan's limited but developing aerospace repair capability. They manufacture engine pins, rotor subassemblies, and aluminum fasteners using imported Swiss-type turning machines. Cooperation with Japanese suppliers ensures quality standards for aerospace-grade parts.

Specializing in micro shafts, precision pins, and stainless-steel valve parts, this company has pioneered the use of Swiss-type sliding headstock technology in Eastern Afghanistan. Their custom production caters to both domestic repair workshops and regional buyers in Pakistan and Iran.

A small but fast-growing start-up, Panjshir Engineering Solutions integrates CAD/CAM modeling with CNC programming. It provides both design assistance and metal part prototyping for industrial clients. Its long-term goal is to become an OEM subcontractor to global Swiss-type CNC machining manufacturers and suppliers.

As Afghanistan continues to establish its industrial foundation, partnerships with Chinese OEM companies provide a major boost. China leads the world in Swiss-type CNC machining, with decades of experience, high-end facilities, and competitive pricing advantages.

Afghan manufacturers typically cooperate with Chinese OEMs in three ways:

1. Outsourcing Component Production:

Afghan companies design or specify the part, while Chinese Swiss-type CNC machining manufacturers and suppliers handle volume production.

2. Equipment and Technology Transfer:

Chinese partners supply advanced CNC machinery, software, and operator training, enabling Afghan factories to increase self-reliance.

3. Joint Ventures:

Shared investment models allow Afghan workshop owners and Chinese suppliers to jointly manage production operations inside Afghanistan.

Such collaboration not only aligns with Afghanistan's localization goals but also enables global buyers to access affordable precision parts from diversified production bases.

Swiss-type CNC machining can accommodate a broad range of materials, depending on part performance requirements. Commonly used materials include:

- Stainless steel: 304, 316L, 17-4PH for corrosion-resistant components.

- Aluminum alloys: 6061 and 7075 for lightweight, high-strength parts.

- Brass and copper: Used in electrical connectors due to excellent conductivity.

- Titanium and Inconel: Selected for aerospace and medical implants.

- High-performance polymers: Such as PEEK or PTFE for biocompatible or insulative components.

Leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan often combine imported materials with local finishing or assembly. This hybrid model ensures flexibility—using verified raw materials while leveraging affordable local operations.

To build international trust, Afghan precision machining companies are emphasizing standardized quality management. Most reputable workshops implement processes such as:

- First Article Inspection (FAI) to confirm dimensions before mass production.

- CMM (Coordinate Measuring Machine) verification for complex geometries.

- SPC (Statistical Process Control) to maintain consistency during large-volume runs.

- Machine calibration checks and material traceability documentation.

Some advanced suppliers are pursuing ISO 9001 or AS9100 certifications to meet international export standards. This allows European and Middle Eastern buyers to cooperate confidently with Afghan machining partners.

The application range for Swiss-type CNC machining manufacturers and suppliers in Afghanistan continues to expand as new industries appear. Currently, the most prominent uses include:

- Energy and power systems: Precision shafts, turbine bushings, and fuel system connectors.

- Automotive and transport: Motorbike engine parts, fasteners, and micro bushings.

- Medical devices: Surgical pins, dental tools, and orthopedic fasteners.

- Defense equipment: Firing pins, cartridge shells, and micro spring housings.

- Industrial machinery: Control valves, sensor housings, and pneumatic components.

As industrialization advances, more sectors will adopt high-precision machining as a standard manufacturing solution.

While large-scale automation remains limited, Afghanistan's machining sector is rapidly digitizing. The use of CAD/CAM design software, real-time monitoring tools, and CNC simulation systems is growing. Universities and vocational schools are also integrating CNC programming and mechatronics into their curriculums, providing a steady stream of technical graduates.

Remote consultation with foreign experts via online platforms allows local programmers to learn advanced methods of toolpath optimization and materials science. Over time, such skills will enable Afghan Swiss-type CNC machining manufacturers and suppliers to upgrade from simple subcontracting to independent product development.

For international businesses considering partnerships in Afghanistan or Central Asia, selecting the right machining supplier is crucial. Here are vital points to evaluate:

1. Equipment profile: Review whether the facility operates authentic Swiss-type lathes with multiple axes and guide bushings.

2. Engineering experience: Experienced operators and programmers are essential for achieving consistent quality.

3. Material expertise: Verify that the supplier can work with your required alloys or engineering plastics.

4. Quality system: Look for documented inspection reports, traceability, and adherence to ISO standards.

5. OEM flexibility: A capable manufacturer should manage both prototype development and volume production.

6. Communication and logistics: English communication, export experience, and efficient packaging are important for seamless cooperation.

Evaluating these elements ensures that foreign buyers can partner confidently with Afghan or hybrid Chinese-Afghan Swiss-type CNC machining manufacturers and suppliers.

As global demand for precision parts continues to rise, Afghanistan's emerging CNC sector offers unique supply opportunities. The country's proximity to Central and South Asia provides logistical advantages for buyers in nearby markets. Additionally, the combination of inexpensive labor, improving technical training, and international mentorship gives Afghan companies a strong competitive edge in niche, low-volume manufacturing.

In the next decade, the Afghan government's efforts to attract industrial investment through tax relief and technology grants are expected to encourage more Swiss-type CNC machining manufacturers and suppliers to enter the local market. With sustained support, Afghanistan could become a small but notable precision machining hub in the region.

Swiss-type CNC machining manufacturers and suppliers in Afghanistan are on a promising path toward modernization. With growing technical expertise, government encouragement, and international collaborations, Afghanistan's CNC industry is evolving from basic fabrication to advanced precision production.

By leveraging the strengths of Chinese OEM technology, local talent, and regional market connectivity, Afghan manufacturers can meet global standards in precision parts production. For international buyers, partnering with Afghan companies today offers cost efficiency, innovation potential, and a strategic foothold in Central Asia's developing manufacturing ecosystem.

Contact us to get more information!

A1: Industries such as aerospace maintenance, defense, automotive repair, and energy systems increasingly use Swiss-type CNC machining for small, high-precision parts.

A2: A few manufacturers are pursuing ISO 9001 and AS9100 certifications, often supported by their Chinese or Indian partners.

A3: Collaboration typically occurs through OEM contracts or direct supplier agreements. Some companies also form partnerships with Chinese Swiss-type CNC machining manufacturers and suppliers for hybrid production.

A4: Lead times range from 2–5 weeks, depending on material sourcing and complexity.

A5: Sourcing from Afghanistan offers cost competitiveness, access to emerging talent, and diversification of supply chains through international partnerships.

1. (https://www.machinetoolworld.org)

2. (https://www.cncmachiningchina.com)

3. (https://www.swisstypemachiningguide.com)

4. (https://www.globalmanufacturinginsight.com)

5. (https://www.asianprecisionindustry.com)

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.