From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-29 Origin: Site

Content Menu

● Understanding Swiss-type CNC Machining

>> Key Features

● Growth of the CNC Machining Industry in Tajikistan

● Top Swiss-type CNC Machining Manufacturers And Suppliers in Tajikistan

>> 1. TajMach Precision Engineering

>> 2. Dushanbe Micron Solutions

>> 3. Central Asia Machinery Co.

>> 4. Pamir Precision Components (PPC)

● Why Partner With Swiss-type CNC Machining Manufacturers in Tajikistan?

>> 2. Strategic Central Asian Location

>> 3. Industrial Policy Support

● Collaboration with Chinese OEM Manufacturers

>> Why Combine Tajik and Chinese Capabilities?

● Applications of Swiss-type CNC Machining Worldwide

>> Industrial Sectors and Products

● Challenges Facing the Industry

>> 2. Limited Supplier Ecosystem

>> 3. Financing and Capital Investment

● Future Outlook: The Rise of Precision Manufacturing in Central Asia

● Frequently Asked Questions (FAQ)

>> 1. What makes Swiss-type CNC machining different from standard CNC turning?

>> 2. Are Tajikistan-based Swiss-type CNC manufacturers competitive globally?

>> 3. What industries in Tajikistan use Swiss-type CNC machining?

>> 4. Can Tajik and Chinese manufacturers collaborate on OEM projects?

>> 5. What are the main challenges for manufacturers in Tajikistan?

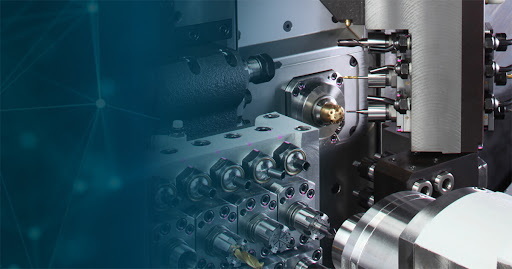

The global precision manufacturing industry has witnessed a powerful transformation over the past decade, driven by automation, globalization, and technological innovation. Among the many machining technologies that define modern industries, Swiss-type CNC machining stands out for its extreme precision and versatility. Initially designed for the Swiss watchmaking industry, this process is now vital in producing micro-components for sectors including medical devices, aerospace, electronics, and automotive systems.

While Switzerland and East Asia have long dominated the precision machining supply chain, Tajikistan has recently started gaining attention as an emerging location for subcontract manufacturing, supported by industrial growth policies and regional trade links. This article explores the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan, detailing their capabilities, advantages, market potential, and the role of Chinese OEM factories in global collaboration.

Swiss-type CNC machining is a specialized turning process where the workpiece is supported by a guide bushing, allowing tools to cut extremely close to the point of support. This unique mechanism minimizes deflection, enabling the production of slender and complex components with outstanding accuracy.

- Sliding headstock design for precise longitudinal motion.

- Guide bushing support system to minimize vibration and tool wear.

- Multi-axis configuration, often 7–9 axes, to complete multiple operations in a single setup.

- High repeatability, ideal for mass production of precision parts.

1. Superior accuracy and surface finish — achievable within a few microns.

2. Efficient production — reduced setup times and consistent automation.

3. Cost savings due to minimal material waste and fewer secondary operations.

4. Wide material compatibility, including stainless steel, titanium, aluminum, brass, and plastic.

Swiss-type CNC machining is especially valued where tolerance and stability determine product quality — in miniature shafts, pins, screws, fittings, and custom connectors.

Tajikistan's manufacturing landscape has traditionally focused on textiles, mining, and hydropower. However, new industrial initiatives under the government's “National Industrial Development Strategy” aim to diversify exports and attract high-precision engineering investments. With improved logistics corridors connecting China, Uzbekistan, and Kazakhstan, the country presents growing opportunities for Swiss-type CNC machining manufacturers and suppliers.

- Infrastructure investment: Industrial parks in Dushanbe, Khujand, and Danghara support small and medium manufacturers.

- Trade partnerships: Preferential trade deals with regional partners reduce export tariffs for mechanical components.

- Technical education programs: Vocational centers now include CNC programming and machine operation courses.

- Foreign collaboration: Tajik companies increasingly partner with Chinese and Russian engineering firms for technology transfer.

The following companies and facilities play a central role in Tajikistan's emerging precision manufacturing ecosystem.

Location: Dushanbe

TajMach Precision Engineering ranks among the leading Swiss-type CNC machining manufacturers and suppliers in Tajikistan. It specializes in producing precision components for hydraulic actuators, industrial automation systems, and electrical housings. The company's Swiss-type CNC lathes and inspection equipment imported from Japan ensure accurate machining for export-quality parts.

Capabilities

- CNC turning and Swiss-type CNC machining for micro-parts.

- CAD/CAM-driven programming and prototyping.

- Material options: aluminum, copper alloys, stainless steel, and carbon steel.

TajMach emphasizes continuous improvement through ISO 9001:2015 certification and tight process control, positioning itself as a competitive supplier within Central Asia.

Location: Dushanbe Free Economic Zone

This medium-sized enterprise focuses on Swiss-type CNC machining for electronic connectors, fluid control components, and miniature fasteners. It is known for combining local machining with technical input from European consultants to achieve precision tolerances.

Key Services

- Multi-axis Swiss turning and micro-milling.

- Custom parts for electronics, telecommunications, and medical prototypes.

- Surface finishing: electroplating, anodizing, and micro-deburring.

With advanced measuring tools such as CMM and digital laser inspection, Dushanbe Micron Solutions continues to improve dimensional reliability and customer confidence.

Location: Khujand Industrial Park

Central Asia Machinery Co. serves multiple industries, including automotive, tooling, and industrial equipment fabrication. By adding Swiss-type CNC machines to its production line, it expands capabilities for small-diameter, high-precision components.

Core Strengths

- Experienced engineering design team.

- Integration of dual-spindle Swiss lathes for multi-axis machining.

- Prototype-to-production support for OEM contracts.

The company also collaborates with regional universities to train operators and improve CNC programming efficiency.

Location: Khujand Free Industrial Zone

Pamir Precision Components focuses on precision parts for aerospace, oilfield, and optical industries. Its Swiss-type CNC machining department produces micro bushings, threaded inserts, fittings, and shafts with excellent repeatability.

Technical Advantages

- Dust-free assembly and precision inspection facilities.

- Materials: titanium alloy, brass, nickel, and hardened steel.

- High-standard metrology equipment ensuring sub-micron accuracy.

With a growing customer base in Turkey, Russia, and the UAE, PPC has become one of the most internationalized Swiss-type CNC machining suppliers in Tajikistan.

Location: Danghara

TechnoTaj Engineering is a new-generation precision workshop focusing on OEM and ODM custom part production. It offers small-batch prototyping and flexible volume manufacturing using state-of-the-art Swiss-type CNC lathes imported from Citizen and Star.

Capabilities

- Machining for high-precision components in aerospace instruments.

- 3D simulation and computer-integrated quality control systems.

- Metal and non-metal machining for hybrid assemblies.

The firm's flexible pricing and reliability attract startups and foreign buyers seeking cost-effective precision manufacturing partners.

Several factors position Tajikistan as a promising region for precision machining collaboration.

Compared to traditional manufacturing hubs, Tajikistan offers significantly lower operational and labor expenses. This enables Swiss-type CNC machining manufacturers and suppliers to offer competitive unit prices for global clients.

Situated near China's western border and integrated with regional road and rail infrastructure, Tajikistan allows shorter shipping times to nearby markets like Uzbekistan, Kazakhstan, Russia, and Afghanistan. It serves as an efficient hub for regional logistics.

Free trade zones provide tax exemptions on equipment imports and raw material purchases, further reducing cost barriers for new investors and foreign partners in precision machining.

New technical programs and university collaborations aim to train more local engineers in CNC operation, CAD/CAM design, and industrial quality assurance, ensuring a sustainable human resource base for future growth.

While Tajikistan excels in cost efficiency and accessibility, Chinese precision manufacturers remain the global leaders in Swiss-type CNC machining services. Many foreign companies source from China due to large-scale production capacity, advanced technology, and proven export experience.

1. Complementary Supply Chain: Tajik facilities can handle small-batch or specialized production, while Chinese OEM factories manage large-scale mass manufacturing.

2. Technology Transfer: Chinese partners provide continuous training and advanced programming expertise.

3. Reduced Lead Times: Regional logistics coordination between western China and Tajikistan streamlines delivery within Asia and Europe.

4. Enhanced Quality: Integrating Chinese precision with Tajik assembly and testing improves efficiency and consistency.

This partnership model enables global buyers—especially those sourcing medical, optical, or automotive micro-components—to achieve both affordability and excellence.

As demand for compact, reliable mechanical parts grows, Swiss-type CNC machining manufacturers and suppliers play an increasingly important role in multiple industries.

- Aerospace: Precision pins, valves, fasteners, and sensor housings.

- Medical Devices: Orthopedic screws, bone plates, and dental surgical tools.

- Electronics: Connectors, pins, plugs, and thermal management hardware.

- Automotive: Fuel injector components, miniature shafts, and custom fittings.

- Instrumentation: Measurement probes, couplings, and calibration pins.

Tajikistan's integration into these value chains offers global buyers flexible sourcing in an evolving market.

Despite promising potential, Tajikistan's precision machining sector still faces operational and developmental challenges.

Many Tajik workshops rely heavily on imported machines and spare parts. Training local technicians for maintenance and programming remains a priority to reduce dependency.

Local access to material suppliers and tooling distributors is limited. Most high-grade steels, cutting fluids, and carbide inserts are imported, increasing costs.

Establishing a full-scale Swiss-type CNC machining facility requires substantial capital. To stay competitive, businesses depend on partnerships or government-supported industrial credit programs.

Global buyers are still unfamiliar with Tajikistan's manufacturing capabilities. Building trust through transparency, certification, and marketing is essential to expand international recognition.

The rise of Swiss-type CNC machining manufacturers and suppliers in Tajikistan reflects a broader shift in the global manufacturing landscape. As companies seek to diversify from traditional hubs, Central Asia's resource-rich and strategically located nations are stepping forward to fill the niche.

Over the next decade, Tajikistan is anticipated to strengthen its precision manufacturing base by:

- Establishing joint ventures with Asian and European partners.

- Investing in smart manufacturing systems and digital supply chain management.

- Promoting vocational training and CNC operator upskilling.

- Offering export incentives to private manufacturers.

Combined with ongoing collaboration with Chinese OEM suppliers, Tajikistan can evolve into a vital bridge linking Central Asian craftsmanship and global engineering standards.

Tajikistan's rise in the precision manufacturing sector marks an encouraging step for Central Asia's industrial transformation. With cost-efficient production, strategic trade location, and an expanding talent pool, the country is positioning itself among emerging Swiss-type CNC machining manufacturers and suppliers on the global stage.

When paired with the large-scale capabilities of Chinese OEM factories, Tajikistan represents an optimal solution for brands seeking quality, flexibility, and regional supply chain resilience. For international buyers, engaging this new manufacturing frontier can open doors to innovation, sustainable sourcing, and competitive industrial partnerships.

Contact us to get more information!

Swiss-type CNC machining uses a sliding headstock and guide bushing to maintain stability, enabling the precise machining of long, slender, or complex components that ordinary lathes cannot handle efficiently.

Yes. Many suppliers follow international standards, leveraging low operational costs and growing technical expertise to compete effectively in regional and global markets.

Industries include medical equipment, aerospace toolmaking, electrical assemblies, and light automotive component manufacturing.

Absolutely. Many Tajik workshops partner with Chinese OEM factories to access advanced technology, joint production models, and efficient logistics.

Key challenges include financing, access to modern machinery, and the need for advanced operator training. However, foreign partnerships are helping bridge these gaps rapidly.

1. (https://www.minindustry.tj)

2. (https://www.swissmem.ch)

3. (https://www.manufacturingglobal.com)

4. (https://www.worldbank.org/en/country/tajikistan)

5. (https://www.adb.org)

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.