From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-28 Origin: Site

Content Menu

● Understanding What a CNC Milling Machine Does

● 1: Research and Identify Profitable Markets

>> Profitable industries that require CNC milling include:

● 2: Offer Custom Machining and Job Work Services

● 3: Design and Manufacture Your Own Products

>> Examples of CNC millable products:

● 4: Cater to Rapid Prototyping and Startup Development

● 5: Subcontract Work to Support Larger Manufacturers

>> Benefits of subcontracting:

● 6: Expand with Design-to-Production Services

● 7: Build Strong Online and Local Presence

>> Digital marketing strategies:

● 8: Improve Efficiency and Reduce Production Costs

● 9: Offer CNC Training and Consultation Services

● 10: Invest in Continuous Upgrades and Innovation

● FAQ

>> 1. What materials can I mill with a CNC milling machine?

>> 2. How much does it cost to start a CNC milling business?

>> 3. Can I run a CNC milling business from my home?

>> 4. How do I find clients for CNC machining services?

>> 5. What industries have the highest demand for CNC milling work?

In today's evolving manufacturing world, CNC technology has revolutionized how products are made. Among these technologies, the CNC milling machine has emerged as one of the most profitable and versatile tools for both industrial production and small-scale entrepreneurship. Whether you are a machinist, a business owner, or a skilled hobbyist, understanding how to make money with a CNC milling machine can help you open new revenue streams and expand your technical capabilities.

This comprehensive guide will walk you through the most effective business models, types of CNC milling applications, profitability strategies, and essential tips for building a sustainable CNC machining business.

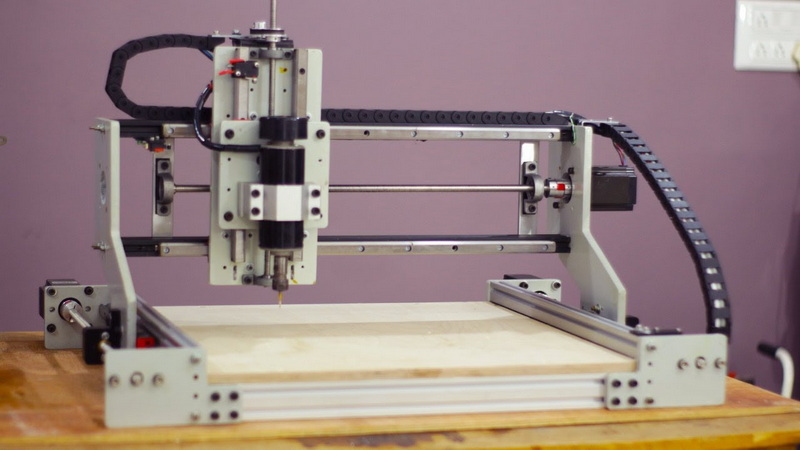

A CNC milling machine uses computer numerical control (CNC) to automate cutting, shaping, and drilling operations on metal, plastic, or composite materials. Unlike manual milling, CNC machines interpret digital instructions to move tools with extreme precision and repeatability. This automation results in high accuracy, consistency, and scalability — three key ingredients for running a profitable manufacturing operation.

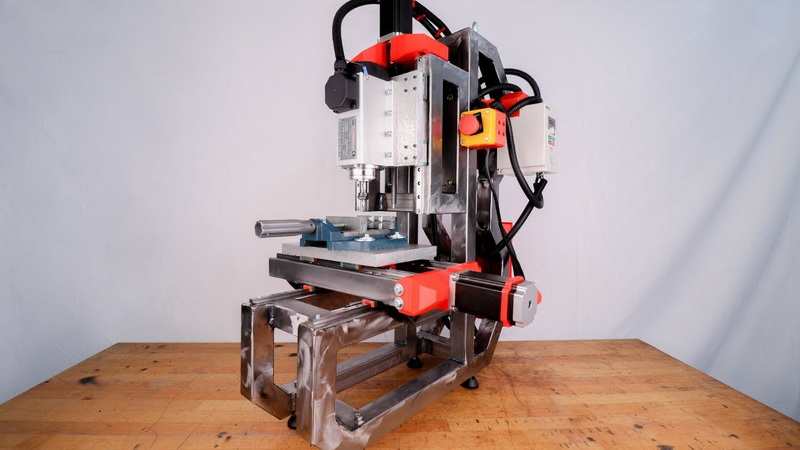

Modern CNC milling machines come in various types, such as 3-axis, 4-axis, and 5-axis configurations. Each additional axis offers more movement and complexity in part geometry. The more advanced the machine, the higher the potential for high-value projects such as aerospace, medical implants, and automotive components.

The goal of your CNC milling business should be to match the machine's capabilities with market demand to achieve maximum profitability.

Making money with a CNC milling machine begins with selecting the right market niche. While CNC machining serves almost every industry, not all markets offer the same returns or accessibility.

- Aerospace sector: Precision parts such as turbine components, actuator housings, and landing gear pieces.

- Automotive industry: Prototyping, engine brackets, custom modification parts, and race car components.

- Medical field: Surgical implants, dental components, and laboratory equipment housings.

- Industrial manufacturing: Custom fixtures, molds, and bearing housings.

- Consumer goods and electronics: Decorative plates, phone stands, and small metal accessories.

Selecting your niche depends on your equipment capabilities, available space, and machining expertise. Focusing on one or two industries helps you build brand credibility and repeat customers.

Providing custom part manufacturing is the fastest way to generate income with your CNC milling machine. Hundreds of companies outsource small batches or specialized components to local machinists rather than purchasing new equipment. You can leverage this by offering job work services for industries that need precision machining but lack in-house resources.

To gain clients, create a digital portfolio showcasing previous jobs, tolerance levels, and available materials. Maintain clear communication with clients about lead times, quality control, and inspection processes. The higher the reliability and dimensional accuracy of your parts, the more frequently clients will return with new projects.

- Offer both prototyping and volume production options.

- Provide competitive quotes while emphasizing quality and precision.

- Maintain strong after-sales support for clients who require component adjustments or refinements.

- Invest in coordinate measuring equipment for dimensional verification.

When managed properly, custom job work ensures consistent workflow and repeat income.

Another creative business direction is to design, produce, and sell your own products using your CNC milling machine. This model gives you full control over profit margins, production pace, and marketing strategy.

- DIY tools and accessories.

- High-end metal phone cases.

- Custom motorcycle or bicycle parts.

- Engraved nameplates or decorative signs.

- Replacement parts for vintage machinery.

Using computer-aided design (CAD) software, you can rapidly develop product prototypes, test market reactions, and then mass-produce the best-selling models. Platforms like Shopify, Etsy, and eBay allow machinists to connect directly with international buyers.

This approach may require an initial product design investment, but once established, it offers passive income potential and brand recognition opportunities.

Startups and engineers frequently need physical prototypes to test fit and functionality before mass production. Unfortunately, not every business has access to precision CNC equipment. This is where your CNC milling machine becomes a valuable service provider.

Offering rapid prototyping services can yield high profit margins because clients are willing to pay a premium for short lead times and innovation support. You can collaborate with product developers to fine-tune their models and help them optimize designs for manufacturability.

- Develop expertise in reading CAD drawings and converting them into toolpaths.

- Keep multiple material grades (aluminum, brass, acrylic) in stock for quick production.

- Use CAM simulation tools to detect toolpath errors before machining.

- Provide confidentiality agreements for patented projects to assure clients.

Prototyping jobs tend to be short, but they can open doors to larger production contracts in the future.

Large manufacturers often run into capacity issues when production demand increases. By partnering with them as a subcontractor, you can take on overflow work or small-batch tasks that their in-house facilities cannot manage efficiently.

- You don't need to spend heavily on marketing since work comes through established networks.

- Regular contracts provide stable monthly income.

- It creates opportunities for continuous skills development and machinery upgrades.

To build trust, prioritize consistency, confidentiality, and delivery punctuality. Over time, your CNC milling machine could become an integral part of your client's supply chain.

Modern clients prefer a single vendor for both design and machining tasks. Therefore, integrating design-to-production services allows you to attract a larger customer base. Instead of simply machining, you can handle CAD modeling, design analysis, and full production.

This multidisciplinary approach helps position your workshop as a one-stop solution for technical projects. The added convenience enables you to charge higher fees and establish your CNC business as a premium service provider.

If your team includes an engineer or CAD designer, this strategy can dramatically increase project value and customer loyalty.

To make your CNC milling machine business visible, strategic marketing is essential. In the digital era, most clients begin their search for machining services online. An informative, SEO-optimized website acts as your 24/7 business representative.

- Create a website showcasing your CNC milling services, material expertise, and contact details.

- Optimize your content using relevant keywords like “CNC machining services,” “precision milling,” and “custom metal parts.”

- Share case studies or project videos demonstrating machine capabilities.

- Create profiles on B2B directories such as ThomasNet, Alibaba, and MFG.

- Encourage clients to leave testimonials and reviews.

A professional digital presence will not only attract new clients but also increase your reputation in the manufacturing community.

Profitability relies on more than just sales volume — operational efficiency plays an equally vital role. Every minute saved in machining improves your return on investment.

- Use high-speed steel or coated carbide tools for longevity.

- Calibrate spindle speeds and feed rates frequently for better chip control.

- Schedule routine maintenance for your CNC milling machine to prevent downtime.

- Implement software automation for repetitive cutting paths.

- Recycle excess metal shavings for scrap income.

Small process optimizations can turn an average CNC workshop into a high-margin business over time.

If you have several years of CNC programming and machining experience, sharing that knowledge can bring additional revenue. Many beginners, technicians, and hobbyists are eager to learn CNC milling processes but lack mentorship.

You can host training workshops, online tutorials, or certification programs that teach G-code programming, tooling, and production workflows. Consulting can also be offered to small machine shop owners who want to improve production speed or accuracy.

Besides creating a new income stream, this also establishes you as an authority in the machining field.

As technology advances, staying updated is vital. Investing in new-generation CNC milling machines with better software integration and automation reduces manual effort and increases output. Upgrading machine controllers, adding 5-axis configurations, or integrating IoT systems enhances both precision and profit potential.

Modern CNC systems also support digital twin simulations and remote operation, making manufacturing far more efficient and safe. With advanced automation, one operator can handle multiple CNC machines at once, dramatically increasing productivity.

Adopting innovative machining practices ensures your workshop remains competitive even as industry standards evolve.

Turning a CNC milling machine into a reliable source of income requires technical skill, market understanding, and business strategy. Whether through custom machining, subcontract projects, or original product creation, the opportunities are endless. By combining craftsmanship with digital marketing and operational efficiency, your CNC milling machine can be transformed from a tool into a long-term investment engine.

With the right approach, consistency, and smart upgrades, even a small CNC milling workshop can evolve into a thriving enterprise serving local and global markets.

Contact us to get more information!

A CNC milling machine can process aluminum, steel, brass, copper, titanium, plastics, acrylic, and composite materials. Tool selection, spindle speed, and coolant use depend on the hardness and finish required.

Starting costs depend on scale. Desktop hobby machines may cost $5,000–$15,000, while industrial models range from $50,000 to $150,000 or more. Include software, tooling, power upgrades, and shop rent in your budget calculations.

Yes, as long as you invest in a compact CNC milling machine and ensure compliance with local safety and noise regulations. Small-scale production of custom parts or engravings can be run from a home workshop.

Create a portfolio site, join industrial directories, and reach out to local engineers and product designers. You can also leverage social media, trade fairs, and forums to gain visibility in your region or abroad.

Industries like aerospace, medical devices, automotive prototyping, and defense manufacturing offer high-paying opportunities. They require extreme precision, which allows you to charge premium rates.

1. (https://www.thomasnet.com/articles/custom-manufacturing-fabricating/what-is-cnc-milling/)

2. (https://machiningtoday.com/how-to-start-cnc-machining-business/)

3. (https://www.autodesk.com/solutions/cnc-machining/overview)

4. (https://cncmasters.com/make-money-with-cnc-machine/)

5. (https://www.engineersedge.com/machining/cnc_milling_machine_basics.htm)

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.