From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-26 Origin: Site

Content Menu

● What Is Swiss-Type CNC Machining?

● Why South Korea Excels in Swiss-Type CNC Machining

>> 1. Advanced Equipment and Automation

>> 2. Skilled Workforce and Technical Expertise

>> 4. Export Orientation and OEM Capabilities

● Top Swiss-Type CNC Machining Manufacturers and Suppliers in South Korea

>> 1. Hanwha Precision Machinery

>> 4. Simmtech Machining Division

>> 5. Daehan Precision Components

● Comparison of South Korean Suppliers to Global Markets

● Trends Shaping the Swiss-Type CNC Machining Industry in South Korea

>> 1. Miniaturization and High-Precision Demand

>> 2. Environmentally Friendly Manufacturing

>> 4. Customization and Flexible Machining

● How to Choose a Reliable Swiss-Type CNC Machining Supplier in South Korea

● Frequently Asked Questions (FAQ)

>> Q1: What materials can South Korean Swiss-type CNC machining suppliers handle?

>> Q2: Do these manufacturers accept small prototype orders?

>> Q3: Are Swiss-type CNC machined parts suitable for the medical industry?

>> Q4: How does South Korea compare to China in terms of Swiss-type machining quality?

>> Q5: Can South Korean suppliers support OEM branding?

South Korea has gained worldwide recognition for its precision machining capabilities, particularly in the Swiss-type CNC machining sector. Known for innovation, consistent quality, and cost-effective production, Swiss-type CNC machining manufacturers and suppliers in South Korea cater to a wide range of industries, including automotive, aerospace, electronics, and medical device manufacturing.

For international buyers looking for stable OEM partnerships and advanced production solutions, South Korea represents a powerful hub for professional Swiss-type CNC machining services with cutting-edge technological advantages and a well-developed industrial ecosystem.

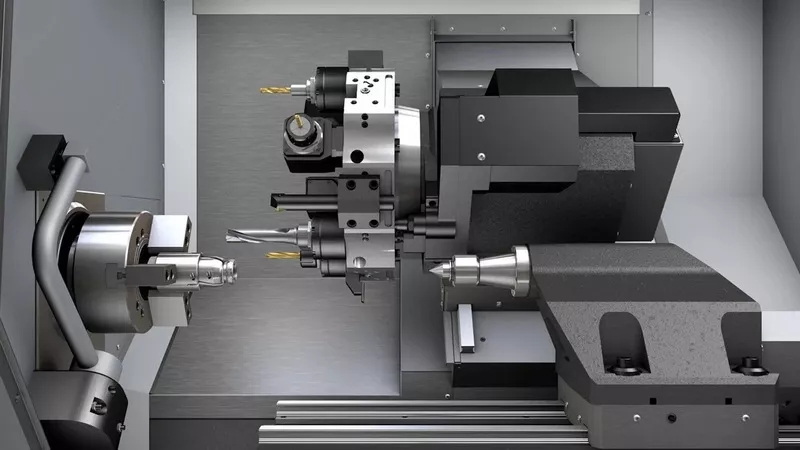

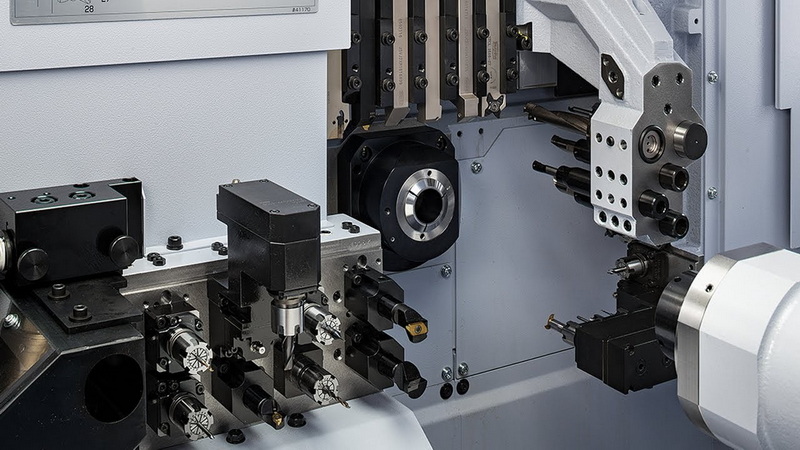

Swiss-type CNC machining refers to a sophisticated process used to manufacture small, complex, and high-precision metal components. The difference between Swiss-type and standard CNC turning lies in the support mechanism for the workpiece.

In a Swiss-type lathe, the part is supported by a guide bushing, allowing the material to stay close to the cutting tool throughout the machining process. This design minimizes deflection, resulting in superior accuracy and smoother finishes.

Key benefits of Swiss-type CNC machining include:

- Extreme precision for micro and long slender components.

- High efficiency in mass production.

- Reduced cycle times with multiple spindles and tools operating simultaneously.

- Excellent repeatability for tightly toleranced parts.

Industries that rely heavily on Swiss-type CNC machining include:

- Medical and dental (surgical instruments, implants, bone screws).

- Aerospace (actuator components, bushings, fasteners).

- Automotive (fuel injection parts, valve components).

- Electronics (connectors, pins, sensors).

South Korea's approach to advanced manufacturing is a blend of technology adoption, skilled engineering, and quality management. The country's Swiss-type CNC machining industry stands out due to several core factors:

South Korean manufacturers consistently integrate multi-axis Swiss-type CNC lathes from leading global brands like Star, Citizen, and Tsugami. Some domestic companies also design custom automation and robotic loading systems, enabling uninterrupted production and efficiency in high-mix, low-volume orders.

With decades of investment in mechanical engineering education and vocational training, South Korea has one of Asia's most skilled machining labor forces. Machine operators and programmers excel in toolpath optimization, precision control, and SPC (Statistical Process Control), ensuring that product tolerances remain consistent at the micron level.

The country's dense manufacturing clusters — especially around Incheon, Ulsan, and Changwon — allow Swiss-type CNC machining suppliers to maintain seamless collaboration with surface finishing, heat treatment, and material forging companies. This integration shortens lead times and ensures competitive pricing for OEM customers.

Most Swiss-type CNC machining manufacturers in South Korea are export-driven. They provide OEM and ODM services to clients in Europe, North America, and Japan. Their familiarity with international standards such as ISO 9001, ISO 13485, and IATF 16949 ensures that global customers receive parts that meet exacting quality demands.

South Korean firms are heavily digitalized. Many adopt smart factory systems with IoT-based machine monitoring and SPC data logging. This transparency allows customers to track order progress in real-time — an advantage rarely available from low-cost production regions.

Below are several leading Swiss-type CNC machining manufacturers and suppliers recognized for their technical strength, experience, and international service reputation.

As a pioneer in CNC technology, Hanwha not only manufactures Swiss-type CNC lathes but also provides precision parts machining services. Its machines are exported globally, while its machining division focuses on automotive and hydraulic system components. The company's technological integration ensures tight tolerances and mass-production stability.

Located in Changwon, Daeil Tech is one of the best-known Swiss-type CNC machining suppliers in South Korea. The company specializes in micro-precision parts for the electronic and aerospace sectors. With capabilities in both prototype development and volume production, Daeil Tech is a trusted partner for OEM clients worldwide.

Kintek Engineering provides custom CNC Swiss turning services using 6-axis and 8-axis lathes. Their expertise covers stainless steel, titanium, and aluminum parts. They are known for flexible order handling, from small-batch R&D parts to full-scale supply for automotive and defense projects.

While primarily recognized for semiconductor components, Simmtech's machining division also provides Swiss-type CNC turning for specialized parts used in high-speed communication and electronic assemblies. Their cleanroom machining environment ensures ultra-clean and burr-free finishes.

This company focuses on OEM Swiss-type CNC machining for medical and fluid control industries. Their advanced inspection systems include CMM, laser micrometers, and optical measurement, guaranteeing exact product conformity to customer drawings.

When compared to Swiss-type CNC machining manufacturers in Japan or Germany, South Korean producers offer a unique advantage in cost-to-performance ratio.

| Feature | South Korea | Japan | Germany | China |

|---|---|---|---|---|

| Average Machining Cost | Medium | High | High | Low |

| Quality Consistency | Very High | Excellent | Excellent | Variable |

| Export Experience | Extensive | Moderate | Extensive | Extensive |

| Lead Time | Short | Medium | Medium | Short |

| Communication & OEM Service | Strong | Technical | Business-focused | Commercial |

This combination of technical reliability and affordability positions South Korea as a preferred Swiss-type CNC machining supplier hub for international enterprises seeking both performance and economic efficiency.

The future of this sector is being shaped by several transformative trends:

With the continued evolution of 5G, IoT, and electric vehicles, component sizes are shrinking while quality requirements rise. South Korean Swiss-type CNC machining manufacturers are adapting by deploying machines capable of handling diameters below 2mm with micron-level accuracy.

Sustainability is becoming a core expectation. More suppliers now use oil mist collection systems, recyclable coolant fluids, and reduced scrap machining processes to align with international environmental standards.

Smart factory implementation is rapidly growing. By linking CNC machines to MES (Manufacturing Execution Systems), data collection becomes automated, enabling predictive maintenance and real-time traceability.

Shorter product cycles push suppliers to develop flexible setups that switch quickly between different part types. Multi-axis Swiss lathes with automatic bar feeders support just-in-time manufacturing for diverse order requirements.

More South Korean suppliers are forming joint ventures or OEM relationships with European and American brands, strengthening technology transfer and quality control collaboration.

Selecting the right manufacturing partner requires more than comparing quotes. Consider the following checklist when evaluating South Korean Swiss-type CNC machining manufacturers and suppliers:

1. Check company certifications – Ensure compliance with international standards such as ISO 9001, ISO 13485, or IATF 16949.

2. Review equipment list – Confirm that the supplier uses modern multi-axis Swiss lathes.

3. Request trial production – Ask for sample runs to assess surface finish and dimensional accuracy.

4. Evaluate communication efficiency – Fast reply and transparent timelines indicate strong project management.

5. Assess production flexibility – Look for small-lot capability and customization support for prototyping.

By following these steps, international buyers can establish strong, long-term relationships with dependable South Korean machining partners.

South Korea's Swiss-type CNC machining manufacturers and suppliers combine precision, automation, and global service experience to deliver world-class quality. Whether it's for aerospace-grade engineering or compact medical parts, these companies exhibit impressive capabilities that rival European and Japanese competitors at a favorable cost.

For international buyers seeking long-term OEM partnerships, South Korea remains a highly strategic sourcing destination — offering technical expertise, quality assurance, and flexible project collaboration through its advanced Swiss-type CNC machining ecosystem.

Contact us to get more information!

A1: Most suppliers can process a range of materials including stainless steel, titanium, aluminum, brass, and specialized medical-grade alloys.

A2: Yes. Many South Korean Swiss-type CNC machining manufacturers support small-quantity prototype orders, helping clients validate designs before mass production.

A3: Absolutely. The high precision and hygiene-ready finishes achieved by these machines make them ideal for implants, dental tools, and surgical components.

A4: South Korea offers higher consistency, more advanced automation, and better process control, though costs may be slightly higher than China's.

A5: Yes, most Swiss-type CNC machining suppliers in South Korea provide private labeling, packaging, and full OEM support for international customers.

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.