From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-26 Origin: Site

Content Menu

● The Rise of Swiss-Type CNC Machining in Russia

● What Makes Swiss-Type CNC Machining Unique

>> 1. The Guide Bushing Mechanism

>> 4. Precision in Micro Parts

● Leading Swiss-Type CNC Machining Manufacturers and Suppliers in Russia

>> Vector Precision Components

>> Technovia Engineering Group

● Why Russian Swiss-Type CNC Machining Companies Stand Out

>> Advanced Technological Infrastructure

>> Robust Engineering Education

>> Competitive Cost and Logistics

>> Commitment to International Standards

● Applications of Swiss-Type CNC Machining in Russian Industries

● Selecting the Right Swiss-Type CNC Machining Supplier

● Future Outlook for Swiss-Type CNC Machining in Russia

● FAQs About Swiss-Type CNC Machining Manufacturers and Suppliers in Russia

>> Q1: What is the main difference between Swiss-type CNC machining and regular CNC turning?

>> Q2: Are Russian Swiss-type CNC machining companies competitive internationally?

>> Q3: What industries rely most on Swiss-type CNC machining in Russia?

>> Q4: Can foreign clients request custom design and small-batch manufacturing in Russia?

>> Q5: How do Russian suppliers maintain product quality for export orders?

Over the past decade, Russia has evolved into one of the rising centers of precision manufacturing in Eastern Europe. Its industrial transformation has been fueled by rapid automation, digital integration, and the increasing demand for high-accuracy components across various industries such as aerospace, automotive, medical devices, and energy. In this context, Swiss-type CNC machining manufacturers and suppliers in Russia have emerged as strong competitors in the global precision engineering market.

Swiss-type CNC machining, originally developed in Switzerland, is famous for producing small, complex parts with extremely tight tolerances. These machines are equipped with a sliding headstock that minimizes vibration during operations, allowing high-precision turning at remarkable speeds. In Russia, the technology has found fertile ground due to its alignment with the country's engineering strengths, robust technical education, and cost-effective production environment.

For international buyers, working with Russian Swiss-type CNC machining manufacturers and suppliers presents an excellent opportunity to source custom components with competitive pricing and reliable quality.

Russia's adoption of high-precision machining technologies has accelerated significantly since the late 2010s. With increased government support for industrial modernization and a growing domestic demand for quality parts, local companies have begun investing heavily in cutting-edge equipment, including multi-axis Swiss-type CNC turning centers.

These technologies allow precision machining of parts smaller than a few millimeters while achieving surface finishes of exceptional quality. Industries such as medical technology, oil & gas instrumentation, and micro-mechanics rely heavily on Swiss-type CNC machining manufacturers and suppliers to achieve consistent performance and design accuracy.

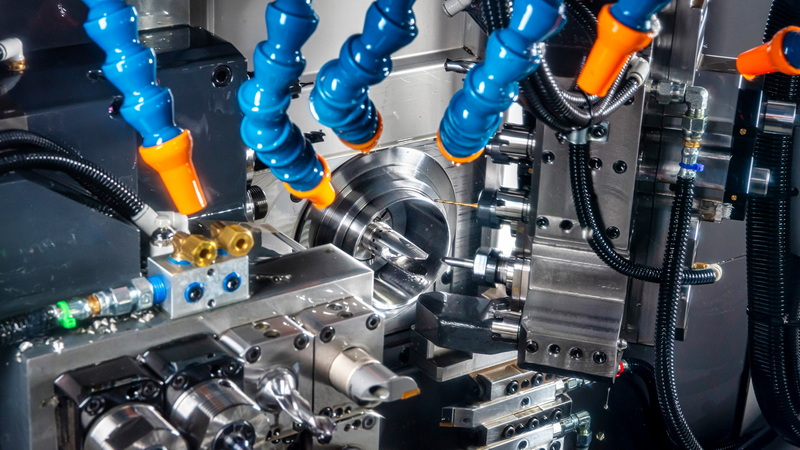

For Russian manufacturers, the appeal of Swiss machining lies not only in its precision but also in its capability to integrate multiple operations—turning, milling, drilling, and tapping—within a single setup. This combination enhances efficiency, reduces waste, and shortens lead times, making Russian workshops increasingly competitive on a global scale.

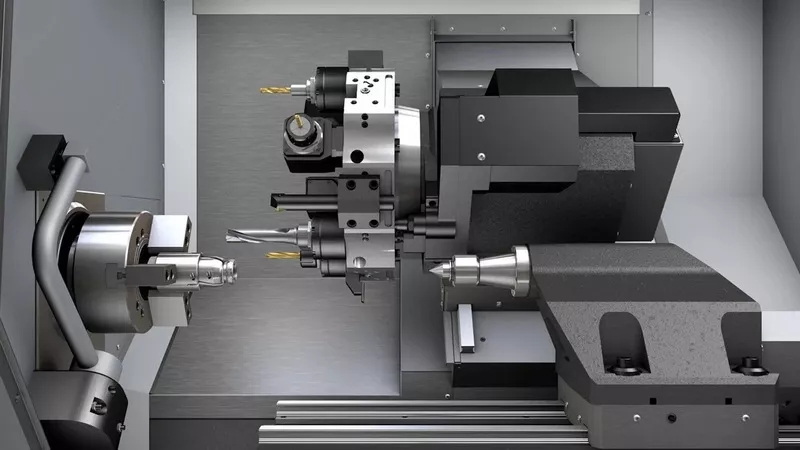

Swiss-type CNC machining differs from traditional turning methods in several fundamental ways:

Unlike standard lathes, a Swiss-type lathe supports the workpiece with a guide bushing close to the cutting zone. This structure significantly reduces vibration, especially for long and slender parts, leading to superior stability and precision.

Modern Swiss-type machines often feature 7 to 12 axes, allowing simultaneous machining on multiple faces of the component. This configuration enables intricate geometries to be produced quickly and consistently.

Most Swiss-type CNC machining manufacturers and suppliers in Russia integrate bar feeders and automated tool changers, ensuring 24/7 production with minimal human supervision. This automation maximizes output while maintaining stable quality levels.

Swiss-type machining is ideal for producing components under 20 mm in diameter, such as miniature screws, shafts, and pins used in electronics, optical instruments, and surgical equipment.

The combination of stable machining and slower finishing speeds helps achieve highly polished surfaces—an essential feature for parts used in medical devices or precision measuring instruments.

PromTech Engineering is a well-established company specializing in high-precision machining for aerospace and defense sectors. The firm's facility is equipped with advanced Swiss turning centers and coordinate measuring systems. Offering complete OEM solutions, PromTech builds its reputation on reliability, traceability, and strict quality management according to ISO 9001 standards.

Vector Precision Components provides full-spectrum Swiss-type CNC machining services including product design review, tool path optimization, and mass production. Its high-speed Citizen and Tsugami machines allow micrometer-level precision. Exporting mainly to Germany and Asia, the company is known for quick order fulfillment and strong communication with international clients.

RusMek Machining focuses on precision parts for the oil & gas, hydraulic, and medical industries. The company employs seasoned engineers skilled in both CAD/CAM and manual inspection processes, ensuring product conformity. Their OEM services include surface treatments, assembly, and packaging tailored for global distribution.

Technovia has positioned itself among the top Swiss-type CNC machining manufacturers and suppliers in Russia. Its process architecture revolves around intelligent production planning and integrated quality assurance. The company continues to expand its international portfolio, supplying precision components to European automotive firms and Asian electronics producers.

MetalProTech Industries primarily serves the medical and custom tooling markets. Its specialization includes surgical implants, dental components, and precision fixtures. Extensive use of automated Swiss-type machines allows the firm to maintain high repeatability and exceptional finish quality. MetalProTech is favored by small and mid-sized foreign buyers for its flexibility and scalable production capacity.

CNCRus Production is renowned for its advanced multi-axis machining setups. The company's facility combines Japanese and Swiss machinery with Russian innovation in process digitization. Its production management system allows real-time monitoring of precision standards, ensuring parts meet tight tolerances. CNCRus supports OEM and ODM projects with packaging and export documentation assistance.

MicroFab Engineering represents the new generation of digital manufacturers in Russia. The company emphasizes rapid prototyping and small-batch production using state-of-the-art Swiss machining centers. Its expertise lies in fabricating high-precision micro components for robotic systems, medical devices, and electronic assemblies. MicroFab also collaborates with research institutes for new materials and precision process development.

Russian machining companies have heavily invested in imported precision tools, high-speed spindles, and measurement devices. Integration with CAD/CAM and simulation technologies allows smooth workflow from design to production. Leading Swiss-type CNC machining manufacturers and suppliers now combine global hardware with locally optimized process software to achieve world-class performance.

Russia has a long-standing engineering tradition. Universities and technical institutes consistently produce specialists with deep mechanical knowledge, contributing significantly to the success of precision machining companies. This skilled workforce ensures that even complex Swiss-type machining projects meet the strictest tolerance requirements.

Compared to Western European countries, Russia provides cost advantages in terms of labor, materials, and energy. Combined with improving transportation infrastructure and export support programs, these factors make Russian machining suppliers a cost-effective option for international buyers seeking high-value partnerships.

Quality assurance remains at the heart of Russian precision engineering. Most leading suppliers are ISO 9001 or ISO 13485 certified. Many also conform to international measurement standards such as GD&T and employ 3D coordinate measuring machines (CMM) for final inspection.

As global industries diversify their supply chains beyond traditional manufacturing hubs, Swiss-type CNC machining manufacturers and suppliers in Russia are focusing on export markets. They have strengthened cooperation with clients in Germany, Italy, China, and the Middle East by offering multilingual communication, transparent pricing, and consistent delivery schedules.

Swiss-type CNC machining's precision and versatility make it applicable across a broad range of industries in Russia:

- Aerospace and Defense: Jet engine pins, fuel nozzles, and high-strength connectors.

- Medical Equipment: Orthopedic screws, dental implants, and surgical tool components.

- Automotive Industry: Brake components, transmission pins, and electronic sensor housings.

- Oil & Gas Engineering: Pressure fittings and corrosion-resistant valve parts.

- Consumer Electronics: Miniature enclosures, threading connectors, and heat-dissipating elements.

The diversity of applications shows how critical Swiss-type CNC machining manufacturers and suppliers have become in sustaining production networks across sectors that demand uncompromising precision.

When selecting the right partner among Russia's many precision manufacturers, consider the following factors:

1. Technical Expertise: Review the supplier's machine capabilities, such as the number of axes and maximum workpiece dimensions.

2. Material Proficiency: Check whether they have experience machining the materials your products require, including exotic alloys or engineering plastics.

3. Quality Control Procedures: Ensure the company uses advanced inspection tools such as digital micrometers, optical comparators, and CMM inspection.

4. OEM & ODM Capacity: Look for suppliers that provide end-to-end service—design consultation, sample making, and production scalability.

5. Export Experience: Established exporters better understand global trade documentation, shipping logistics, and compliance requirements.

6. Customer Support: Evaluate their responsiveness, reporting transparency, and post-sale communication practices.

A thorough supplier audit combining technical review and reference checking helps build confidence before committing to long-term partnerships.

The future of Swiss-type CNC machining manufacturers and suppliers in Russia looks promising. Macro trends in automation, smart manufacturing, and AI-driven production monitoring are reshaping the industry. Companies are implementing data-driven production management systems to improve productivity, machine uptime, and traceability.

Additionally, as additive manufacturing begins complementing subtractive machining, hybrid processes are gaining traction. The combination of 3D printing and Swiss-type turning will soon enable faster development of complex part geometries with reduced material waste.

Environmental considerations are also driving sustainability initiatives across the sector. Many Russian suppliers are adopting coolant recycling systems, waste segregation, and energy-efficient machining strategies to minimize their environmental footprint while improving operational efficiency.

With these developments, Russia's position as a key precision machining exporter in Eurasia is expected to strengthen further.

Russia's precision engineering sector has evolved rapidly, supported by skilled labor, modern equipment, and a commitment to innovation. The country's Swiss-type CNC machining manufacturers and suppliers stand out for their technical strength, cost efficiency, and dedication to international quality standards.

From miniature surgical components to aerospace-grade fittings, these companies demonstrate that Russia can compete with the best in the global precision machining industry. As international demand for reliable OEM and ODM partners continues to grow, Russian machining suppliers are set to become key contributors to the global manufacturing ecosystem, combining precision with performance for clients worldwide.

Contact us to get more information!

Swiss-type CNC machining uses a sliding headstock that moves the workpiece through a guide bushing, allowing greater support and accuracy—ideal for manufacturing small, slender, and high-precision components.

Yes. Russia provides a combination of engineering talent, advanced production equipment, and lower operational costs, enabling its manufacturers to compete effectively in global OEM markets.

Aerospace, automotive, medical, electronics, and oil & gas sectors rely heavily on this machining technology due to the complexity and tight tolerances of their components.

Most Russian suppliers welcome OEM partnerships and prototype development projects. They offer design analysis, feedback, and small-batch production before scaling up to mass manufacturing.

Quality control involves digital inspection systems, ISO-certified processes, precision measurement, and detailed production reporting to ensure consistency across batches.

1. https://www.promtech.ru

2. https://www.vectorprecision.ru

3. https://www.rusmek-mfg.ru

4. https://www.technovia.ru

5. https://www.metalprotech.ru

6. https://www.cncrus.ru

7. https://www.microfab-eng.ru

8. https://www.made-in-russia.com

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.