From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-26 Origin: Site

Content Menu

● Understanding Swiss-type CNC Machining

● The Evolution of Portugal's Precision Engineering Sector

● Leading Swiss-type CNC Machining Manufacturers and Suppliers in Portugal

>> 2. Metalúrgica Central da Trofa (MCT)

>> 3. Indmetal Precision Components

● Why Portugal Has Gained International Attention

>> Highly Skilled Technical Workforce

>> Innovation and Machine Integration

>> Excellent Cost-to-Quality Ratio

● Industries Empowered by Swiss-type CNC Machining

● Technological Developments Driving Portugal's CNC Industry

● How International OEMs Partner with Portuguese CNC Manufacturers

● Selecting the Right Swiss-type CNC Machining Partner

● Future Outlook: Portugal's Role in the Global Supply Chain

● FAQs about Swiss-type CNC Machining in Portugal

>> Q1: What differentiates Swiss-type CNC machining from conventional turning?

>> Q2: Are Portuguese machining companies capable of large-scale export?

>> Q3: Which materials are commonly processed by Swiss-type CNC machines in Portugal?

>> Q4: How do Portuguese companies ensure quality assurance?

>> Q5: Can international OEMs order custom or confidential parts?

Precision manufacturing lies at the heart of modern engineering. Among the many techniques pushing the boundaries of accuracy and efficiency, Swiss-type CNC machining has become one of the most important technologies. Known for producing highly detailed components with microscopic tolerances, this process has reshaped the global supply chain for miniature mechanical parts.

In Portugal, Swiss-type CNC machining manufacturers and suppliers are emerging as leading players in the European precision parts industry. Combining technical expertise, advanced machinery, and robust export practices, Portuguese companies now compete with the best in Germany, Switzerland, and Japan. This article explores the top Swiss-type CNC machining manufacturers and suppliers in Portugal, their technologies, applications, and the growing international demand for their services.

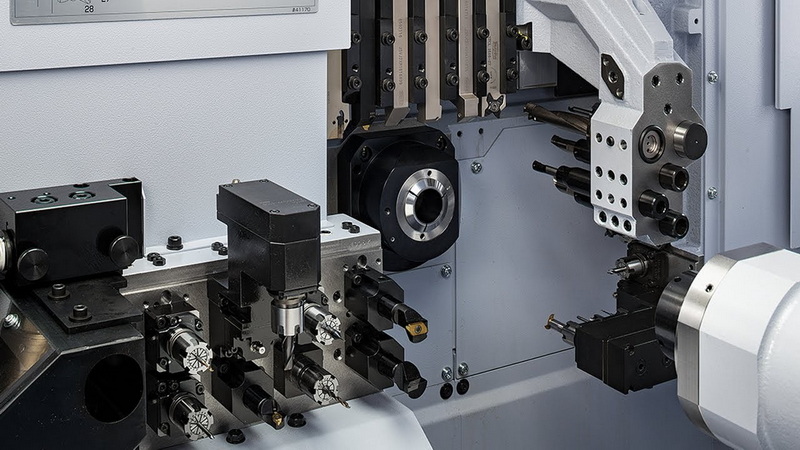

Swiss-type CNC machining, also known as “sliding headstock turning,” was originally developed in Switzerland for producing watch components. The machines feature a guide bushing that supports the workpiece close to the cutting tool, resulting in incredible precision even with very slender or delicate materials.

Unlike conventional lathes where the part extends unsupported, Swiss-type CNC machines move the material through a stationary guide while multiple tools cut simultaneously. This enables dimensional tolerances as tight as ±0.002 mm, ideal for high-complexity parts across aerospace, medical, and electronics sectors.

The key benefits of Swiss-type CNC machining include:

- High precision and repeatability. Perfect for tiny parts or complex geometries.

- Faster cycle times. Multiple tool operations occur concurrently.

- Reduced vibration. The guide bushing stabilizes the workpiece, minimizing surface defects.

- Material versatility. Works effectively with stainless steel, titanium, brass, bronze, or plastics.

From micro-screws for hearing aids to connectors for aerospace systems, Swiss-type CNC machining defines the gold standard of precision engineering worldwide.

Portugal's industrial roots have long been tied to metal fabrication, mold-making, and automotive component supply. Over the past decade, however, the nation has aggressively modernized its manufacturing landscape. Automation, robotics, and advanced CNC equipment have become standard across many facilities.

Government initiatives encouraging Industry 4.0 adoption have pushed Portuguese manufacturers to digitize and upgrade production. Today, Swiss-type CNC machining manufacturers and suppliers in Portugal are known for delivering superior quality, competitive pricing, and fast turnaround times.

Key drivers behind Portugal's CNC machining growth include:

- Strategic geographic proximity to major European markets such as Spain, France, Germany, and the UK.

- Export-focused industrial zones in Porto, Braga, and Aveiro designed for precision manufacturing.

- Access to skilled labor from vocational and technical institutes specializing in mechanical engineering.

- Integration of automation and robotics, improving consistency, minimizing waste, and shortening lead times.

Portugal's flexible business regulations, competitive energy costs, and stable infrastructure have also made it a preferred outsourcing hub for international OEMs seeking dependable European suppliers.

Below is a curated list of established Portuguese companies specializing in Swiss-type CNC machining. These suppliers have earned reputations for engineering quality, technical excellence, and export reliability.

Location: Oliveira de Azeméis

Specialization: Precision mold components and tooling inserts.

Moldit operates high-precision CNC turning centers, including Swiss-type systems for micro parts and fine finishing operations. With decades of experience in metal tooling and mold components, the company exports to over 20 countries. Its production line is fully digitalized, integrating CAD/CAM simulation with real-time tool monitoring.

Location: Trofa

Specialization: CNC turning, prototyping, and assembly services.

MCT is a pioneer in integrating multi-axis Swiss-type machines for fast, flexible production. The firm provides machining for aerospace fittings, hydraulic valves, and electronic housings. With strict adherence to ISO 9001 and IATF 16949 standards, MCT delivers parts that meet demanding automotive specifications.

Location: Braga

Specialization: Swiss-type machining for stainless steel, titanium, and brass materials.

Indmetal's focus on small-diameter components (under 5 mm) makes it a key supplier for optics and telecommunication sectors. The company combines cutting-edge Citizen and Tornos CNC equipment with advanced metrology and automated inspection systems.

Location: Porto District

Specialization: Swiss-type CNC turning and complex assembly.

A family-owned enterprise, Alcino Silva Precision is admired for flexibility and attention to detail. It delivers low- to medium-volume production for clients in the electronics, robotics, and medical device sectors. The firm's vertical integration ensures full control from machining to quality inspection and packaging.

Location: Porto

Specialization: Medical precision parts, dental and orthopedic components.

FERP focuses exclusively on medical-grade machining. Its clean-room inspection facilities and traceability systems ensure total compliance with ISO 13485 medical device standards. It also supports clients with document validation for FDA and CE approvals.

Location: Aveiro

Specialization: Custom parts manufacturing and CNC design consulting.

Lusimec has become a benchmark for advanced mechanical solution development. It provides end-to-end OEM support—from concept design and rapid prototyping to mass production. Through strategic collaboration with universities, Lusimec incorporates the latest materials and machining simulations into its processes.

Location: Lisbon

Specialization: High-volume Swiss-type CNC manufacturing for export.

CNC Precision PT offers digital supply chain integration to optimize order processing and global logistics. Its smart factory framework uses IoT monitoring to predict tool wear and machine downtime before they occur, ensuring consistent performance and delivery.

Together, these companies illustrate how Swiss-type CNC machining manufacturers and suppliers in Portugal combine tradition, innovation, and technical mastery to compete globally.

Portugal's precision machining growth is not accidental—it reflects a conscious industrial transformation supported by both public and private sectors. Several differentiating strengths deserve attention:

Portuguese machinists receive professional training in precision engineering, programming, and CAD/CAM design. English proficiency among management and engineers ensures smooth communication with international partners.

Factories in Portugal increasingly deploy hybrid technologies integrating Swiss-type machining with micro-milling, grinding, and laser cutting—all under a unified digital workflow. This enables one-stop production and reduces external subcontracting costs.

Portugal's operational costs remain 20–30% lower than Western Europe's industrial hubs while maintaining strict quality compliance. This ratio appeals to foreign OEMs, especially mid-market brands seeking affordable but certified European supply chains.

With major seaports (Leixões, Lisbon) and efficient highway connections, Portugal offers excellent logistics for shipping precision components to Europe, North America, and the Middle East. Export documentation and trade compliance are streamlined under EU trade frameworks.

The rise of Swiss-type CNC machining suppliers in Portugal has benefited numerous global sectors:

- Medical and dental devices: Micro pins, screws, bone plates, orthopedic instruments, and surgical implants.

- Aerospace and defense: Fuel system connectors, actuator parts, sensor housings, and aircraft fasteners.

- Automotive: Injection nozzles, valve bodies, precision bushings, and safety system fittings.

- Electronics: Miniature connectors, threaded pins, and optical couplings.

- Industrial equipment: Pneumatic fittings, hydraulic valve seats, and automation components.

Portuguese suppliers increasingly collaborate with international R&D teams to co-develop prototypes and test parts, ensuring faster time-to-market and greater design innovation.

Technology adoption remains central to the success of Portuguese Swiss-type CNC machining manufacturers and suppliers.

Key advancements shaping the industry include:

- AI-based quality control. Predictive analytics monitor vibration patterns, tool fatigue, and cutting conditions.

- Digital twins and simulation. Virtual replicas of machining operations allow optimization before production begins.

- Collaborative robotics (cobots). Used for secondary operations such as deburring, polishing, and part transfer.

- Data traceability and MES systems. Each component carries a digital record of settings, materials, and inspection data—crucial for medical and aerospace compliance.

- Sustainability practices. Installation of coolant filtration systems, recycling of metal chips, and energy-efficient lighting.

These technological developments enhance productivity, uphold environmental standards, and strengthen Portugal's position in Europe's advanced manufacturing network.

Global OEMs often choose Portuguese CNC suppliers for their mix of competence, agility, and dependability. The collaboration process typically unfolds through structured stages:

1. Technical consultation: OEM teams share product drawings, tolerances, and target lead times.

2. Feasibility analysis: The Portuguese manufacturer uses CAD simulation to evaluate and refine manufacturability.

3. Prototype fabrication: Initial samples are machined, reviewed, and fine-tuned for performance validation.

4. Mass production: Approved parts are produced using Swiss-type CNC machines equipped for continuous multi-tool operation.

5. Final inspection and logistics: Each batch undergoes coordinate measuring machine (CMM) verification before global shipping.

This process ensures precision, traceability, and timely delivery for high-value industries such as medical equipment or defense systems.

When sourcing Swiss-type CNC machining manufacturers and suppliers in Portugal, consider several key points to secure the best collaboration outcome:

- Confirm the company's certifications such as ISO 9001, IATF 16949, or ISO 13485 for medical components.

- Evaluate technical capabilities including maximum part length, material range, and tolerance limits.

- Review machine brands (e.g., Citizen, Tornos, Star) and the number of active production units.

- Request detailed quality documentation, including measurement protocols and surface finish reports.

- Assess project communication, responsiveness, and language capacity during pre-contract discussions.

- Visit the production site or request virtual tours to verify working conditions and technological readiness.

Choosing a qualified partner ensures manufacturing efficiency, cost optimization, and consistent quality across production cycles.

As global manufacturing priorities shift toward precision, customization, and digital integration, Portugal stands poised for exponential growth. The synergy between Swiss-type CNC machining and AI-driven manufacturing technologies creates a solid foundation for expansion.

In the next decade, analysts expect Portuguese machining firms to strengthen partnerships with Asian and North American industries, driving co-engineering models rather than traditional subcontracting. Many Portuguese firms are also exploring additive manufacturing (3D printing) integration with Swiss-type machining for hybrid part production.

This evolution positions Portugal as a sustainable, high-precision manufacturing ecosystem—bridging Europe's quality standards and Asia's cost efficiency.

Portugal has firmly positioned itself as one of Europe's most dynamic centers for high-precision machining. Its Swiss-type CNC machining manufacturers and suppliers combine innovation, quality, and agility to meet the evolving demands of advanced industries. Through ongoing investment in automation, workforce training, and sustainability, Portuguese firms now provide competitive and dependable alternatives to traditional hubs like Switzerland and Germany.

For global OEMs, Portugal offers more than just manufacturing capacity—it offers partnership, collaboration, and confidence in every micron of precision delivered. As technological boundaries continue to expand, the Portuguese Swiss-type CNC machining industry stands ready to take its place among the world's top leaders in precision engineering.

Contact us to get more information!

A1: Swiss-type machining stabilizes the workpiece using a guide bushing, enhancing accuracy for complex, slender parts and allowing simultaneous multi-tool operations to reduce production time.

A2: Yes. Many leading Portuguese suppliers already serve European automotive and aerospace markets and maintain export infrastructure for global shipments.

A3: Stainless steel, titanium, aluminum, brass, copper, and engineering plastics are widely used across medical, automotive, and electronics sectors.

A4: Most firms follow strict ISO-based quality processes with 100% dimensional inspection, surface roughness tests, and statistical process control (SPC) documentation.

A5: Absolutely. Portugal's CNC machining suppliers frequently handle OEM contracts involving proprietary designs, sealed documentation, and NDAs.

1. https://www.moldit.pt

2. https://www.mct.pt

3. https://www.indmetal.pt

4. https://www.ferp.pt

5. https://www.portugalglobal.pt

6. https://www.aicep.pt

7. https://www.eurometal.pt

8. https://www.lusimec.pt

9. https://www.starcnc.com

10. https://www.tradeportugal.gov.pt

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.