From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-26 Origin: Site

Content Menu

● Understanding Swiss-type CNC Machining

● Why Italy Excels in Precision CNC Manufacturing

● Leading Swiss-type CNC Machining Manufacturers in Italy

>> 1. Maro Srl Precision Engineering

>> 2. Officine Meccaniche Pagani

>> 5. Torneria Automatica Colombo

● Technical Capabilities of Italian Swiss-type CNC Manufacturers

● Industries Served by Italian Swiss-type CNC Suppliers

● OEM Collaboration Advantages

● Italian-Chinese Collaboration in Precision Component Manufacturing

● Quality Standards and Certification Systems

● Digital Transformation and Industry 4.0 Adoption

● Challenges and Future Trends

● Frequently Asked Questions (FAQs)

>> 1. What makes Swiss-type CNC machining different from standard CNC turning?

>> 2. Which sectors rely most on Italian Swiss-type CNC machining?

>> 3. Can Italian CNC suppliers handle custom OEM projects?

>> 4. What tolerances can Italian Swiss-type CNC machines achieve?

>> 5. How do Italian and Chinese collaborations benefit global customers?

Italy has long stood as one of Europe's powerhouses of industrial precision. From the automotive valleys of Turin to the mechanical hubs of Bologna and Vicenza, the country boasts an impressive network of Swiss-type CNC machining manufacturers and suppliers that serve global industries with exceptional quality. Their evolution from traditional mechanical workshops into digitally advanced CNC production centers exemplifies Italy's unique blend of craftsmanship and technological innovation.

As international competition intensifies, Italian machining suppliers continue to lead in micro-precision production for critical sectors such as aerospace, medical technology, telecommunications, and automotive engineering. This article provides an in-depth overview of Italy's most respected Swiss-type CNC machining manufacturers and suppliers, examines their competitive strengths, and explores how global OEM buyers can benefit from collaborating with these high-precision Italian specialists.

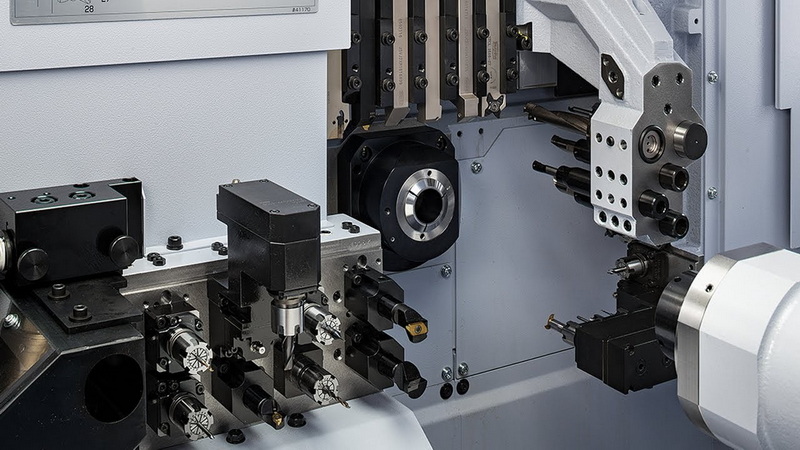

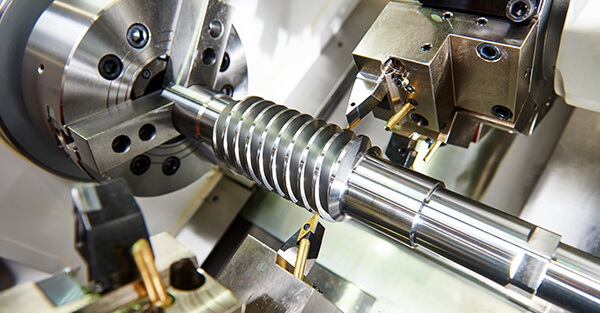

Swiss-type CNC machining—often called sliding headstock or Swiss automatic turning—is an advanced manufacturing process originally developed in Switzerland for the watch industry. Unlike traditional lathes, a Swiss-type lathe allows the workpiece to move axially through a guide bushing as cutting tools operate close to the support point. This unique design minimizes vibration and ensures superb accuracy even for long, slender, or micro-sized components.

Modern Swiss-type CNC machines typically offer:

- Multi-axis capability (up to 12 controlled axes) for simultaneous operations.

- Automatic bar feeders allowing uninterrupted, high-efficiency production.

- Live tooling for drilling, milling, threading, or engraving in a single setup.

- Sub-spindle systems enabling complex back-working without manual intervention.

The result is a faster, more precise, and highly cost-effective process—ideal for OEMs that require parts with tolerances as tight as ±0.002 mm.

Italy's success as a leader in Swiss-type CNC machining manufacturers and suppliers is rooted in a deep industrial tradition supported by technical education, design culture, and small-business innovation. Several key drivers explain the country's success:

- Advanced engineering skills: Italian CNC technicians are globally recognized for their ability to optimize machines for performance and precision.

- Cluster-based industry: Concentrated industrial zones in Lombardy, Piedmont, and Emilia-Romagna create highly efficient ecosystems of component suppliers, tool makers, and surface treatment experts.

- Continuous modernization: Italian manufacturers invest heavily in Industry 4.0 systems—such as machine connectivity, predictive maintenance, and AI-driven quality monitoring—to improve yield and efficiency.

- Sustainability orientation: Many companies now integrate environmentally responsible lubrication systems, recyclable materials, and energy-efficient machining processes.

This foundation gives Italian suppliers a strong competitive edge in both low- and high-volume CNC production.

Here are some of the country's most reliable Swiss-type CNC machining manufacturers and suppliers, each known for its specialization, high-precision tolerances, and quality assurance.

Based in Bologna, Maro Srl combines decades of experience in mechanical design with top-tier Swiss-type CNC technology from Star and Citizen Machinery. Its facility supports full OEM and ODM production, handling stainless steel, aluminum, brass, and titanium components with dimensions from 1 mm to 38 mm. The company also applies automated inspection with Zeiss coordinate measuring systems, ensuring consistent output quality.

Maro Srl's main advantages include short lead times, precision repeatability, and flexible production—making it a trusted supplier for clients in Europe, North America, and Asia.

Located near Milan, Officine Meccaniche Pagani offers custom CNC turning and small-diameter component production. The company's Swiss-type lathes integrate live tooling and Y-axis control for complex geometries without secondary machining steps. They serve industries such as fluid control, optics, and electrical engineering, providing both prototype development and batch manufacturing.

Their emphasis on fast communication, strict tolerance management, and just-in-time delivery systems differentiates Pagani from other Swiss-type CNC machining manufacturers and suppliers in northern Italy.

A branch of the global Tornos Group, Tornos Italia operates not only as a machine supplier but also as a contract manufacturer through its certified partner network. The company leverages industry-leading multi-spindle Swiss-type lathes capable of performing high-precision turning, cross-drilling, and simultaneous milling operations. This combination of hardware and engineering support makes Tornos Italia a valuable partner for demanding projects.

Located in Vicenza, Meccanica Bressan provides elite-level precision machining services primarily for aerospace and defense sectors. The company integrates 3D model simulation and CAM-based programming to minimize programming errors and shorten production cycles. Its quality control department is ISO 9001, AS9100, and ISO 13485 certified, positioning Bressan among Italy's most technically competent Swiss-type CNC machining manufacturers and suppliers.

Torneria Automatica Colombo, established over four decades ago in Turin, produces high-volume precision parts for electronics, hydraulics, and automotive systems. Equipped with energy-efficient Star SR series machinery, Colombo continuously upgrades its technology to meet the evolving global demand for eco-friendly production. The company's environmental and safety management practices align with ISO 14001 and ISO 45001 standards.

Italian firms excel not only in machinery but also in precision-oriented engineering. Their advanced technical setups commonly include:

- Five to twelve axis CNC systems for high-complexity components.

- Automatic tool changers and in-cycle measurement control for improved tool life.

- CNC grinding, milling, and threading attachments integrated into the same turning operation.

- Custom fixture design and adaptive tooling for unique OEM component geometries.

- Batch tracking and computerized inspection storage, ensuring full production traceability.

Such deep technical integration helps Italian Swiss-type CNC machining manufacturers and suppliers reduce human interference, minimize waste, and streamline quality checks for every production stage.

The precision levels achieved by Italian CNC manufacturers attract clients from a wide range of industries, including:

- Medical – Surgical instruments, implants, dental abutments, and diagnostic device components.

- Aerospace – Engine fittings, hydraulic connectors, and lightweight fasteners.

- Automotive – Sensor housings, valve pins, injector bodies, and transmission shafts.

- Telecommunication – Micro antennas, contact pins, and optical fiber holders.

- Industrial automation – Multi-axis couplings, miniature bearings, and metering valves.

These sectors rely on Swiss-type machining for parts that require exceptional reliability, small tolerances, and surface finish uniformity—areas where Italian firms truly excel.

Working with Italian manufacturers offers OEM buyers a complete turnkey experience. Key benefits include:

1. Tailored engineering support: Italian suppliers frequently co-design parts with international engineers, optimizing manufacturability and material use.

2. Prototype-to-production efficiency: Thanks to digital twin technology and rapid modeling, lead times for prototypes are significantly shortened.

3. Flexible order management: Many companies offer small-batch production for testing or product launches before scaling to full-volume manufacturing.

4. Transparent communication: English-speaking engineering and sales teams make project supervision smooth for clients across different time zones.

This collaborative approach aligns perfectly with global sourcing models that prioritize quality, efficiency, and long-term partnerships.

A notable development in recent years is the growing collaboration between Italian and Chinese manufacturers. Chinese OEM factories, known for cost-effective large-batch production, increasingly supply semi-finished or complementary components to Italian Swiss-type CNC machining manufacturers and suppliers. These Italian firms then perform final tolerance finishing, assembly, or certification testing before exporting to Western brands.

Such cross-border partnerships combine Italian process know-how with China's manufacturing scale—yielding cost-efficient supply chains that preserve European quality benchmarks. This synergy demonstrates how global precision manufacturing is evolving toward cooperative production networks rather than isolated national systems.

Italian suppliers place heavy emphasis on certification, process documentation, and in-house testing. Key quality management standards include:

- ISO 9001 – General quality assurance for manufacturing.

- ISO 13485 – Specific for medical equipment and healthcare component suppliers.

- IATF 16949 – Automotive industry requirement for precision component suppliers.

- AS9100 / EN 9100 – Aerospace manufacturing compliance framework.

- ISO 14001 – Environmental impact control and waste management.

These systems serve as official indicators of reliability and discipline among Italy's Swiss-type CNC machining manufacturers and suppliers, enhancing trust and transparency in global partnerships.

Smart factory technologies are transforming Italy's CNC machining industry. Leading manufacturers now rely heavily on real-time monitoring and process automation. Technologies such as IoT-enabled machines, AI-driven quality inspection, digital twins, and machine learning analytics allow factories to predict tool wear, optimize lubrication, and detect defects automatically.

Many companies also implement ERP and MES software systems that connect production, procurement, and logistics. As a result, buyers can monitor project progress remotely and receive digital reports with traceability data—enhancing transparency between suppliers and clients.

While Italy's Swiss-type machining sector thrives on precision and innovation, it also faces challenges that shape its strategic direction:

- Energy and raw material cost inflation.

- Shortage of young CNC technicians as older generations retire.

- Integration of sustainability targets mandated by European Union policies.

Despite these challenges, the outlook remains promising. The growth of electric vehicles, renewable energy systems, and wearable medical devices generates steady demand for micron-scale metal and polymer components. Italian Swiss-type CNC machining manufacturers and suppliers are increasingly exploring advanced alloys, biocompatible materials, and hybrid machining to meet future market needs.

Italy continues to dominate as one of the world's leading hubs for Swiss-type CNC machining manufacturers and suppliers, blending art-like craftsmanship with modern industrial intelligence. Whether serving aerospace giants, medical innovators, or automotive pioneers, Italian companies consistently deliver exceptional results driven by precision, efficiency, and design innovation.

For global OEMs, collaborating with these Italian suppliers ensures access to industry-leading machining quality, transparent project management, and a future-ready digital supply chain. As technology, sustainability, and international cooperation reshape manufacturing worldwide, Italy's expertise in Swiss-type CNC machining remains both a benchmark of excellence and a trusted resource for manufacturers everywhere.

Contact us to get more information!

Swiss-type CNC machining supports the workpiece through a fixed guide bushing, which ensures higher stability and accuracy, particularly for slender or small-diameter parts.

Major sectors include aerospace, medical devices, automotive sensors, electronics, and industrial automation, all requiring high accuracy and excellent surface finishes.

Yes. Many firms handle OEM and ODM orders, providing joint R&D, CAD optimization, and rapid prototyping as part of their standard services.

Most Italian facilities maintain dimensional tolerance within ±0.002 mm and surface roughness as low as Ra 0.2 μm, depending on material and design complexity.

Italian suppliers ensure precision finishing and certification, while Chinese partners contribute cost-effective large-batch capabilities, enabling high-quality yet competitively priced components.

1. https://www.marosrl.it

2. https://www.officinepagani.it

3. https://www.tornos.com

4. https://www.meccanicabressan.it

5. https://www.torneriaautomatica.com

6. https://www.madeinitaly.gov.it

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.