From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-23 Origin: Site

Content Menu

● Understanding CNC Turning and Its Importance

● Why Hungary Has Become a CNC Turning Leader

>> 1. Prime Location and EU Access

>> 2. Highly Qualified Workforce

>> 3. Cost-Efficient yet High-Quality Production

>> 4. Technological Advancement and Automation

● Top CNC Turning Services Manufacturers and Suppliers in Hungary

>> 2. Flexman Robotics & Machining

>> 3. Miskolc Precision Engineering Ltd.

>> 5. Budatech Manufacturing Co.

>> 6. Győr Advanced Machining Group

● Key Benefits of Partnering with Hungarian CNC Turning Manufacturers

>> 1. Strict Quality Control and Certification

>> 2. Flexible OEM and ODM Services

>> 3. Scalable Production Capacity

>> 4. Strong Communication and European Reliability

>> 5. Sustainable Manufacturing Practices

● Collaboration Between Hungarian and Chinese CNC Suppliers

● Future Trends Shaping the Hungarian CNC Turning Industry

>> 1. Smart Factory Digitalization

>> 2. Integration with Additive Manufacturing

>> 3. Advanced Robotics and Automation

>> 4. Sustainable Material Engineering

>> 5. Custom Digital Supply Chain Platforms

● How to Select the Right CNC Turning Supplier in Hungary

● Frequently Asked Questions (FAQ)

>> 1. What are CNC turning services mainly used for?

>> 2. Are Hungarian CNC manufacturers competitive compared to other EU countries?

>> 3. Can Hungarian suppliers provide full OEM services?

>> 4. Do these companies accept small orders or prototypes?

>> 5. How does logistics work for international buyers?

As precision manufacturing continues to shape the future of industrial production, CNC Turning Services Manufacturers and Suppliers have emerged as key players driving innovation, automation, and quality in global supply chains. In recent years, Hungary has gained recognition as a strong European hub for high-precision machining, offering competitive advantages in engineering talent, cost structure, and logistics accessibility.

For international companies seeking reliable OEM solutions, the CNC turning industry in Hungary provides a perfect balance between advanced European quality standards and flexible cooperation models suitable for global buyers, wholesalers, and industrial brands.

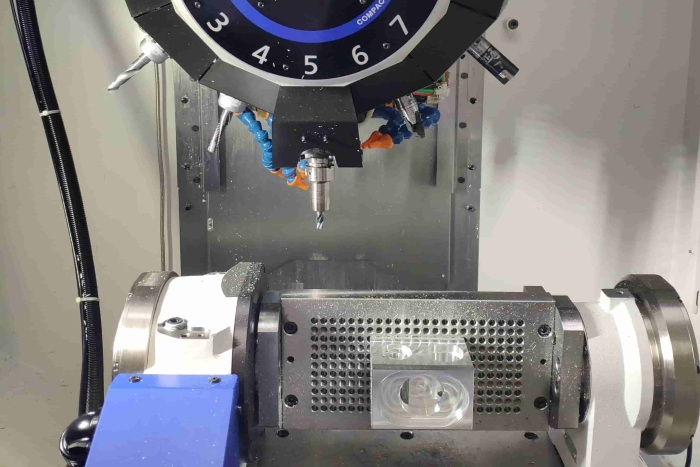

CNC turning is one of the most essential machining processes used by modern manufacturers. It involves rotating a workpiece on a lathe while cutting tools remove material to produce smooth, precisely measured surfaces and shapes—mainly cylindrical components like shafts, pins, bushings, and flanges.

Unlike traditional manual turning, CNC (Computer Numerical Control) systems allow engineers to program exact specifications into the machine, ensuring every part matches the digital CAD model within micron-level tolerance.

These precise and repeatable capabilities make CNC turning indispensable for industries that demand consistent performance and reliability, including:

- Automotive and heavy equipment

- Aerospace and defense

- Electronics and telecommunications

- Medical device manufacturing

- Energy and hydraulic systems

Hungarian CNC Turning Services Manufacturers and Suppliers have built a strong reputation for quality engineering practices, rapid prototyping, and scalable production systems that meet both European and global market needs.

Hungary's manufacturing sector has modernized rapidly over the past two decades, benefiting from both foreign direct investment (FDI) and local expertise in precision machinery, automation, and mechanical engineering. The following factors make Hungary an ideal destination for CNC machining cooperation:

Located in Central Europe, Hungary serves as a strategic logistics bridge between Western Europe, the Balkans, and Eastern European markets. This central location enables fast, cost-efficient transport to Germany, Austria, and Italy—countries that rely heavily on CNC-turned components for automotive and industrial assembly.

Hungary's technical universities and engineering schools produce thousands of skilled machinists, mechanical designers, and production technologists annually. Their technical proficiency supports advanced CNC turning services that meet strict precision standards, helping the country compete globally against more mature European manufacturing bases.

Hungarian CNC turning suppliers maintain cost advantages over Western Europe due to lower wage and facility costs while adhering to EU-regulated quality management systems such as ISO 9001 and IATF 16949. This balance enhances competitiveness without sacrificing product integrity or delivery reliability.

Hungarian machining workshops integrate 5-axis turning, robot-assisted loading systems, CAD/CAM programming, and in-line quality measurement, ensuring superior control over accuracy and repeatability. Many factories have embraced Industry 4.0 automation, merging robotics with data analytics for smart production monitoring.

Below are some of Hungary's leading manufacturers and suppliers providing full-turnkey CNC solutions for industrial sectors worldwide. These companies represent the depth and sophistication of Hungary's machining capabilities.

Based in Budapest, Preciziós Gép Kft. is widely recognized for its comprehensive CNC turning and milling expertise. The company supports clients in automotive and mechanical engineering sectors, producing high-tolerance components from stainless steel, aluminum, and tool steels. Their precision inspection systems guarantee batch consistency.

Flexman Robotics combines traditional machining expertise with automation technology. They employ robotic arms for tool handling, enabling continuous, unmanned operation. This approach allows competitive lead times for aerospace and renewable energy clients seeking complex, customized parts.

Situated in one of Hungary's industrial heartlands, Miskolc Precision Engineering focuses on CNC-turned and milled components for European vehicle brands. Their continuous improvement practices—lean manufacturing, real-time production tracking, and cross-department quality audits—ensure seamless cooperation with global OEMs.

Delta CNC Solutions stands out for its versatility. The company provides short-run production, 3D prototyping services, and high-volume metal turning for industrial hardware, hydraulics, and connector applications. Their engineers offer design modifications that optimize machining efficiency and reduce waste.

The Budapest-based Budatech Manufacturing Co. serves electronics and communication sectors, producing high-precision miniature components and housings. Their hybrid CNC-milling machines produce intricate geometries for PCB mounting and micro-connectors, making them a preferred partner for international tech firms.

With decades of experience, Győr Advanced Machining Group provides integrated CNC solutions combining mechanical design, digital simulation, and final assembly. They cater to demanding clients requiring small-tolerance components for high-speed motion systems, robotics, and defense equipment.

Each of these CNC Turning Services Manufacturers and Suppliers in Hungary distinguishes itself through innovation, multi-axis machining capability, and strict quality control that meets international requirements.

Choosing CNC Turning Services Manufacturers and Suppliers from Hungary brings both operational and strategic advantages for global buyers. These benefits include:

Hungarian firms operate under EU-regulated standards, with ISO 9001, ISO 14001, or IATF 16949 certifications commonly held. Sophisticated inspection tools, such as CMM machines and laser measurement systems, ensure part uniformity and dimensional consistency.

Most suppliers provide OEM and ODM CNC machining support, handling the entire product creation cycle—from concept design and prototyping to full-scale production. This flexibility is vital for clients who require co-engineering and innovation input during design validation.

Hungary offers both small custom workshops and large industrial plants equipped for mass production. This diversity allows clients to choose cost-effective suppliers depending on order quantity, precision requirements, and delivery schedules.

Hungarian manufacturers maintain strong English communication standards and direct liaison with technical teams. Their proximity and EU business framework ensure transparent trade compliance, making cooperation efficient and legally secure.

Many suppliers prioritize energy-efficient processing, waste reduction, and recycling initiatives. Environment-conscious machining aligns with European sustainability goals and benefits clients pursuing eco-friendly supply chains.

While Hungary leads in European precision machining, its partnership potential with Chinese CNC turning manufacturers creates new synergies across global supply chains. Chinese CNC factories offer cost-effective bulk production, while Hungarian partners provide local assembly, fine finishing, and logistics support within Europe.

For example, Chinese producers can handle large-volume, semi-finished parts for export, while Hungarian manufacturers perform secondary operations like surface finishing, inspection, and customization before European distribution. This model combines efficiency, regional accessibility, and high technical quality—ideal for brands managing cross-continental OEM strategies.

Such collaborations also reduce customs delays and improve responsiveness to final-market changes. As global supply chains diversify post-pandemic, more Hungarian and Chinese manufacturers are forming stable technical and commercial partnerships.

Hungary's CNC Turning Services Manufacturers and Suppliers are evolving rapidly in response to global trends and technological shifts. Key developments include:

Digital twins and AI-driven production management are helping companies simulate machining processes before cutting any material. These tools minimize human error and extend machine life through predictive maintenance.

Hybrid machining centers that merge CNC precision with 3D printing are gradually emerging. These systems enable complex geometries that were previously impossible with subtractive manufacturing alone.

Collaborative robots (cobots) now handle repetitive machining tasks safely alongside human operators. They dramatically reduce downtime and support rapid scaling for high-volume projects.

Hungarian firms are increasingly experimenting with eco-friendly alloys, biocomposite materials, and energy-efficient machining strategies. These environmentally responsible innovations strengthen long-term competitiveness.

Some modern CNC suppliers offer online order tracking, instant quotation systems, and real-time quality dashboards. These digital interfaces make B2B communication smoother and data-driven.

When choosing the best CNC turning partner, international buyers should evaluate both technical competence and long-term reliability. Consider the following best practices:

1. Request Technical Documentation: Review samples, tolerance reports, and previous manufacturing case studies to confirm capabilities.

2. Check Equipment Portfolio: Ensure the company uses up-to-date lathe systems, automated loading devices, and precision measuring instruments.

3. Understand Lead Times and MOQ: Confirm whether the supplier can balance cost with delivery flexibility for your production schedule.

4. Evaluate After-Sales Support: Good suppliers provide maintenance, replacement parts, and responsive communication even after project completion.

5. Assess Financial and Legal Stability: Consider the company's operational history, financial health, and compliance with EU trade laws.

By following these guidelines, foreign companies can secure competitive, long-term partnerships with Hungary's most competent CNC Turning Services Manufacturers and Suppliers.

Hungary's CNC Turning Services Manufacturers and Suppliers have proven themselves as reliable partners in the global precision manufacturing landscape. Combining advanced equipment, skilled engineers, and cost-effective operation, Hungarian firms deliver components that meet the highest industrial and OEM standards.

For overseas brands, wholesalers, and manufacturers, Hungary offers not only a technically capable CNC sector but also strategic access to the EU market. The country's ongoing digital transformation, automation adoption, and sustainability initiatives ensure that its CNC industry will continue to thrive and compete internationally.

As global supply chains evolve, partnerships between Hungarian and Chinese precision manufacturers provide even greater competitiveness, flexibility, and market reach—making Hungary a cornerstone of the European CNC turning ecosystem.

Contact us to get more information!

CNC turning services are primarily used to produce precise cylindrical components such as screws, shafts, bushings, and connectors that require consistent dimensional accuracy for industrial, automotive, and electronic applications.

Yes. Hungarian CNC manufacturers often offer the same high technical standards as Western Europe but at significantly lower operating costs, making them ideal for cost-sensitive projects without sacrificing quality.

Absolutely. Most CNC Turning Services Manufacturers and Suppliers in Hungary offer integrated OEM/ODM solutions including design assistance, machining, post-processing, and final assembly.

Yes. Many Hungarian suppliers specialize in short-run or prototype production, helping clients test product designs before large-scale manufacturing.

Due to Hungary's central EU location and strong logistics network, international clients benefit from efficient road, rail, and air freight, ensuring rapid and reliable deliveries to all European destinations.

1. https://hiprecisionmachining.hu/

2. https://www.flexman.hu/

3. https://www.preciziosgep.hu/

4. https://www.budatech.hu/

5. https://www.delta-cnc.eu/

6. https://www.gyorprecision.com/

7. https://www.hungarytrade.gov.hu/

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Russia. Learn about their advanced technology, OEM services, export capabilities, and key advantages that position Russia as a growing hub for global precision engineering.

Discover the top Swiss-type CNC machining manufacturers and suppliers in South Korea offering high-precision OEM services for global industries. Learn about their capabilities, equipment, and key advantages in precision engineering.

Explore the leading Swiss-type CNC machining manufacturers and suppliers in Portugal. Learn how their precision, technology, and OEM expertise make Portugal a top destination for high-accuracy component production in automotive, aerospace, and medical industries.

Discover Italy's top Swiss-type CNC machining manufacturers and suppliers specializing in precision components for aerospace, medical, automotive, and industrial markets. Learn about their technology, certifications, OEM services, and collaboration opportunities for global buyers.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Arab States. Learn about key companies, OEM services, advanced technologies, and market trends driving precision manufacturing growth in the Middle East.