From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2026-01-26 Origin: Site

Content Menu

● Understanding Swiss-Type CNC Machining

● The Rapid Industrial Growth in Arab States

● Leading Swiss-Type CNC Machining Manufacturers and Suppliers in Arab States

>> 1. Advanced Precision Industries – Saudi Arabia

>> 2. Emirates CNC Solutions – United Arab Emirates

>> 3. Qatar Precision Engineering – Qatar

>> 4. NileCNC Industries – Egypt

>> 5. Oman Precision Components Co. – Oman

● Evaluating the Right Supplier: Key Considerations

>> Important Selection Factors

● Advantages of Partnering with Arab CNC Manufacturers

● OEM and Customization Capabilities

● Collaboration Between Arab and Chinese Manufacturers

● Technology Integration and Industry 4.0 Readiness

● Workforce and Skills Development

● Challenges Facing the Regional Industry

● Green Manufacturing and Sustainability Efforts

● Market Outlook and Future Opportunities

● FAQs about Swiss-Type CNC Machining Manufacturers and Suppliers

Swiss-type CNC machining has become a cornerstone of precision manufacturing across multiple industries. Known for its unmatched accuracy and efficiency, this technology plays a vital role in producing complex and miniature components for sectors such as aerospace, automotive, electronics, and medical devices. In the Arab States, the manufacturing industry is undergoing rapid modernization, and more firms are investing in high-precision machining equipment.

For foreign buyers, distributors, and OEM clients, choosing the top Swiss-type CNC machining manufacturers and suppliers in the Arab region means gaining access to superior craftsmanship, cost efficiency, and a growing network of skilled engineers. This article dives deep into the leading providers, market trends, and strategies for building successful partnerships with Arab manufacturers.

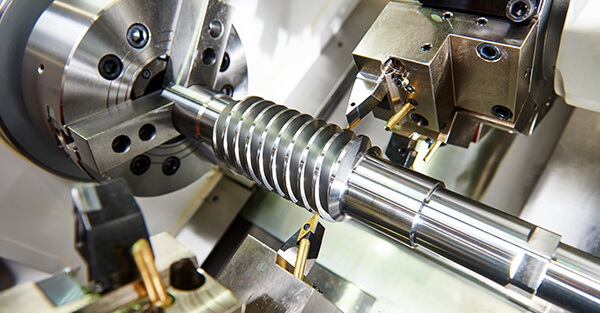

Swiss-type CNC machining, often referred to as Swiss-turning, is a process that uses a sliding headstock lathe. The bar stock moves through a guide bushing while stationary cutting tools shape the part. This design minimizes vibration and ensures micrometer-level precision, even for slender or long parts.

Unlike conventional lathes, Swiss machines can perform turning, milling, drilling, and threading in one setup, reducing time and enhancing productivity. These machines can operate with up to 12 axes, which allows complex geometries and highly detailed features to be produced efficiently.

Today's Swiss-type CNC machining manufacturers and suppliers integrate real-time monitoring systems, high-speed tool changers, and coolant control technologies for better surface finish and consistency. As a result, they can handle intricate projects that demand extreme accuracy and repeatable outcomes.

Over the last decade, industrial diversification has become a strategic goal for many Arab economies. Oil-dependent nations are channeling resources into advanced manufacturing sectors to drive innovation and create new export opportunities.

- Saudi Arabia's Vision 2030: Encourages domestic production of high-precision industrial parts, medical devices, and aerospace components.

- UAE's Operation 300bn: Stimulates the growth of local manufacturing capabilities to enhance national self-sufficiency and global competitiveness.

- Qatar National Vision 2030: Aims to nurture technology-driven industries and sustainable manufacturing ecosystems.

- Egypt's Industrial Modernization Program: Attracts international investors to establish joint ventures in mechanical and electronic manufacturing.

These initiatives have led to the establishment of training centers, technology parks, and innovation hubs, which strengthen the regional foundation for Swiss-type CNC machining manufacturers and suppliers.

Based in Dammam, Advanced Precision Industries (API) is recognized for its technical expertise in turning small-diameter, tight-tolerance parts. The facility uses specialized Swiss machines suited for complex, multi-axis designs. API caters to sectors like defense, energy, and industrial automation.

Advantages include:

- ISO 9001 and AS9100 compliance.

- In-house engineering and reverse design assistance.

- End-to-end OEM service for batch and prototype quantities.

Emirates CNC Solutions operates a fully automated workshop in Dubai equipped with next-generation CNC Swiss lathes. The company has rapidly expanded due to its strong customer service and reliability.

Key strengths:

- Experience with titanium, Inconel, and engineering plastics.

- Real-time production tracking for transparent communication.

- Exports to Europe, Japan, and North America.

Qatar Precision Engineering is a leader in manufacturing precision shafts, valves, and electronic connectors. Its engineering team is trained in advanced Swiss machining programs that ensure high accuracy for custom designs.

Highlights:

- CNC capacity for high-volume batch production.

- Comprehensive quality inspection using CMM and laser metrology.

- Excellent record in aerospace and medical supply chains.

Located in Cairo, NileCNC Industries serves international markets with premium precision machining and tooling fabrication. The company offers full OEM and ODM services tailored to client requirements.

Core benefits:

- Skilled workforce experienced in European machining techniques.

- Flexible MOQ policies ideal for SMEs and new developers.

- Rapid quotation and technical drawing evaluation services.

This Omani manufacturer combines traditional craftsmanship with modern CNC automation. Oman Precision Components supplies components for aerospace, robotics, and instrumentation manufacturers worldwide.

What makes them stand out:

- 24/7 production capability with intelligent scheduling.

- Multi-language customer support for global clients.

- Consistent product quality backed by strict inspection protocols.

When selecting a Swiss-type CNC machining manufacturer or supplier, buyers should thoroughly assess the company's technological infrastructure, quality control system, and communication efficiency.

1. Technological Competence: Ensure the supplier uses advanced multi-axis Swiss lathes from brands like Citizen or Star.

2. Material Expertise: Capability to process materials like stainless steel, titanium, brass, and engineering plastics.

3. Quality Inspection: The presence of CMM machines, optical measurement systems, and SPC process tracking.

4. Certifications: Compliance with ISO, AS, or CE standards related to your product industry.

5. After-Sales Support: The ability to provide replacements, redesign, or minor modifications post-delivery.

Arab suppliers often maintain shorter production cycles compared to Western counterparts due to regional flexibility and streamlined operations. Countries such as the UAE and Saudi Arabia host efficient transport infrastructure, which ensures faster global shipping.

Arab Swiss-type CNC machining manufacturers and suppliers present clear benefits for global clients:

- Cost Efficiency: Lower labor and facility costs enhance overall pricing competitiveness.

- Strategic Location: Easy access to Europe, Africa, and Asia makes logistics seamless.

- Government Incentives: Tax-free export zones and manufacturing subsidies attract foreign collaborations.

- Modern Infrastructure: High-speed internet, automation labs, and industrial zones improve productivity.

- Skilled Workforce: Increasing enrollment in technical colleges and global training programs ensures consistent quality.

Such benefits position the Arab States as reliable and flexible partners for foreign OEM projects.

OEM (Original Equipment Manufacturing) services are the backbone of many Swiss-type CNC machining manufacturers and suppliers in the region. These companies serve as engineering partners who can transform 2D drawings or 3D models into finished products.

- Medical Devices: Bone screws, catheters, and surgical inserts.

- Aerospace Components: Fuel injectors, bushings, and nozzles.

- Automotive Systems: Shafts, pistons, and fittings.

- Robotics and Electronics: Connectors, pins, and encoder housings.

- Industrial Equipment: Hydraulic couplers and machine tool inserts.

Leading Arab firms often employ prototype validation cycles and use ERP systems for production tracking. International clients benefit from transparent order management and guaranteed confidentiality under NDAs.

A growing trend is the collaboration between Arab and Chinese machining enterprises. Chinese partners contribute technical knowledge, tooling innovation, and volume scalability, while Arab partners manage client communication and final assembly.

This partnership creates a hybrid model that delivers:

- Cross-border design optimization.

- Reduced costs for raw materials and logistics.

- Balanced order allocation between Asia and the Middle East.

Chinese precision part manufacturers from Guangdong, Zhejiang, and Jiangsu often handle large-volume Swiss-type CNC machining while Arab suppliers focus on quality control, branding, and regional distribution.

Arab manufacturers are investing heavily in Industry 4.0 transformations, emphasizing automation, data-driven decision-making, and smart factory ecosystems.

- IoT-Connected Machines: Real-time data tracking across production lines for predictive maintenance.

- Automatic Tool Correction: Software-integrated sensors that adjust tool offset to achieve consistent precision.

- Digital Twin Simulation: Virtual machining environments for accuracy prediction and energy optimization.

- AI Quality Inspection: Machine vision algorithms detect microscopic defects and surface irregularities.

By combining these innovations with traditional craftsmanship, Arab Swiss-type CNC machining manufacturers and suppliers are joining the ranks of global leaders in industrial digitalization.

Many Arab countries have realized that equipment investment alone cannot ensure long-term success. Training programs, apprenticeship initiatives, and partnerships with technical universities have been established to cultivate a new generation of machinists and engineers.

Vocational colleges in Saudi Arabia, UAE, and Egypt now offer hands-on CNC programming and quality control courses using real Swiss-type machines. This educational advancement guarantees a continuous supply of skilled professionals who can meet international manufacturing standards.

Despite fast progress, there are still challenges to overcome.

- Supply Chain Dependence: Some raw materials and tooling systems are still imported.

- Technological Gaps: Not all SMEs can afford multi-axis Swiss lathes.

- Power Costs: Energy consumption remains relatively high in certain regions.

- Brand Recognition: Many capable suppliers are still developing global marketing presence.

However, with increasing foreign investment and cooperative ventures, these challenges are gradually diminishing. The next decade promises enormous potential for Arab machining industries to compete globally.

Sustainability is becoming a key metric for modern buyers. Arab Swiss-type CNC machining manufacturers and suppliers are adapting green practices to reduce carbon footprints:

- Using biodegradable coolants and recyclable lubricants.

- Adopting energy-efficient servo motors.

- Recovering heat from production systems for reuse.

- Implementing waste segregation and metal recycling programs.

Such efforts not only meet regulatory standards but also demonstrate commitment to corporate responsibility—an increasingly important factor for European and American buyers.

The market outlook for Swiss-type CNC machining manufacturers and suppliers in Arab States is promising. Rising global demand for precision components, coupled with government backing, creates a favorable environment for expansion.

According to international industry analysts, the precision component market in the Gulf region is projected to grow by over 9% annually during the next five years. Growth drivers include diversification in renewable energy projects, advanced mobility sectors, and regional defense manufacturing programs.

Companies that integrate smart technologies, skilled labor, and sustainable practices will enjoy a significant competitive edge.

The Arab States are rapidly emerging as strategic destinations for high-precision manufacturing. Thanks to strong government backing, advanced infrastructure, and integration with Industry 4.0 technologies, the region has created a thriving ecosystem of Swiss-type CNC machining manufacturers and suppliers. These companies combine cost effectiveness with technical excellence, making them suitable partners for global OEMs in aerospace, automotive, and medical sectors.

With continuous collaboration between Arab and Chinese manufacturers, improved skill development programs, and sustainability initiatives, the precision engineering industry in the Arab world is on track to become one of the most competitive in the global marketplace. For international importers, engaging with these companies today can provide enduring advantages in product quality, pricing, and supply chain resilience.

Contact us to get more information!

1. Which industries commonly rely on Swiss-type CNC machining in the Arab States?

Key industries include aerospace, automotive, energy, defense, and medical devices—sectors that require precise, repetition-friendly production.

2. How to ensure a supplier meets strict quality requirements?

Request ISO or AS certificates, ask for sample parts, and inquire about their inspection methods such as CMM reporting and SPC tracking.

3. Do Arab CNC suppliers accept small-volume OEM projects?

Yes. Many support low MOQ orders for customized parts and prototypes, ideal for new product developers or startups.

4. What is the average production lead time?

Depending on complexity, most suppliers deliver within 3–6 weeks. Some offer express services for repeat customers.

5. Are communication and technical documentation available in English?

Absolutely. Most suppliers have multilingual engineers fluent in English, ensuring seamless collaboration with foreign clients.

1. https://www.saudiindustrialdevelopment.gov.sa

2. https://www.madeintheuae.gov.ae

3. https://www.qatarindustrial.gov.qa

4. https://www.industrialmod.gov.eg

5. https://www.omanmanufacturing.gov.om

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Russia. Learn about their advanced technology, OEM services, export capabilities, and key advantages that position Russia as a growing hub for global precision engineering.

Discover the top Swiss-type CNC machining manufacturers and suppliers in South Korea offering high-precision OEM services for global industries. Learn about their capabilities, equipment, and key advantages in precision engineering.

Explore the leading Swiss-type CNC machining manufacturers and suppliers in Portugal. Learn how their precision, technology, and OEM expertise make Portugal a top destination for high-accuracy component production in automotive, aerospace, and medical industries.

Discover Italy's top Swiss-type CNC machining manufacturers and suppliers specializing in precision components for aerospace, medical, automotive, and industrial markets. Learn about their technology, certifications, OEM services, and collaboration opportunities for global buyers.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Arab States. Learn about key companies, OEM services, advanced technologies, and market trends driving precision manufacturing growth in the Middle East.