From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

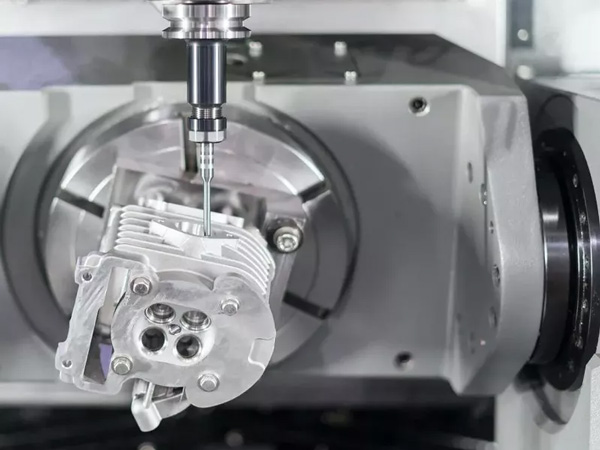

Should a component be turned or milled? Is 3-axis machining sufficient, or does the project require 5-axis? Okay, a wrong selection of the CNC machining process may result in costly delays, tolerances, or excess spending. In this CNC machining processes comparison, we will describe each major method along with a concise overview in a clear, practical manner.

Hopefully, this will help in making decisions that are cost-effective and tailored to project specifics. So, let’s dive in!

“CNC machining processes refer to a set of manufacturing processes which involve the removal of material from a piece in order to shape a certain part.”

Each of these processes is managed with the help of a computer, which aids in moving the tools with pinpoint precision. This is the reason why CNC stands for Computer Numerical Control. In contrast with 3D printing, it is a subtractive manufacturing method, meaning more material is used than needed initially, and the excess is gradually removed in order to reveal the desired shape.

Well, this method is prevalent, especially in industries like manufacturing, due to its exceptional accuracy and consistency.

This is a question that comes to the mind of numerous design and engineering professionals. The answer is rather straightforward: Every component differs. Some might have holes and curves, while others might need to have smooth finishes or sharp edges. Therefore, there is no single approach that can be used for all shapes, sizes, and materials.

To address all of these requirements, different processes have emerged. Each of them caters to a specific task, be it cutting metal blocks, shaping cylinders, or surface finishing.

In this blog, we will explain the different types of processes so that you can have a better perspective of them. First, let’s have a quick look at each.

With CNC milling, the workpiece remains stationary while the cutting tool rotates and extracts material as though it were peeling off layers. This approach is optimal for components that have flat surfaces, slots or pockets.

This process is often used for design and other engineering components that require holes, angles, and intricate 3-dimensional shapes. Well, CNC milling is a precise and flexible process that works with metals and plastics.

CNC turning operates slightly differently. In this instance, the workpiece is rotatable while the tool remains stationary. The tool engages in cutting operations along the surface of the workpiece.

Therefore, this is ideal for producing circular or cylindrical components like rods, pipes, and shafts. Generally speaking, turning is more common than milling and is especially useful when components require symmetry about a centerline, and is quite a bit faster than milling.

There are several options for adding holes. A spinning drill bit typically performs the worst and most basic—CNC drilling. For increased accuracy and improved surface finishes, holes can also be bored and reamed.

Boring increases the size of a hole while improving its position, and reaming gives the final touch with a specific size and super smooth surface. Okay, these processes are often performed in combination to increase the total efficiency of the parts.

There are other categories of CNC manufacturing processes that deserve attention in addition to the most common ones mentioned above.

Grinding is the process of finishing or smoothing a surface with the aid of a spinning wheel.

EDM, or Electrical Discharge Machining, is another process that uses electric sparks to erode hard metals.

These techniques are indispensable when intricate details or high-quality finishes are required beyond the capability of conventional tools.

Each method has specific functions to perform in CNC machining. Some methods are better suited for flat shapes, and others for round shapes or intricate details. This is why knowing these different types of CNC machining processes is crucial to prepare for a project. It helps you avoid mistakes by enabling you to select the right tool for the task.

Alright! Now, here in this section, we will analyse the differences between CNC machining processes, their principle, pros, cons, applications, and more. Stay connected!

CNC routing vs milling? Let’s figure it out now! CNC milling and CNC turning are the two primary processes in subtractive manufacturing within CNC. Both processes remove material from a solid workpiece, but their movement mechanics differ. Milling utilises a spinning tool and a fixed workpiece, and turning spins the workpiece against a fixed tool.

Core Difference

In which of the two processes does the tool spin, or does the part? This is the key distinction.

In CNC milling, the cutting tool is the part that rotates while the workpiece is stationary.

In CNC turning, the workpiece rotates and the cutting tool is stationary.

Suitable Parts

Milling is best suited to square, flat, or irregular parts with complex features.

Turning is ideal for cylindrical, round, and rotational parts.

How It Works

In CNC milling, a rotary cutting tool traverses a fixed workpiece along the X, Y, and Z axes to remove material and shape complex contours.

In CNC turning, the workpiece is secured in a chuck and spun at high rotational speeds. A static tool moves along the surface to form the cylindrical features.

Advanced Precision Capabilities: A milling machine is one of the best options when dealing with complex and multifaceted components with high precision requirements.

Versatile Material Capability: Able to work with challenging materials such as steel, titanium, aluminium, and even engineering plastics.

Multi-Functional Capability: Performs a variety of operations such as drilling, slotting, contouring, and surface finishing in a single setup.

Time Inefficiency for Round Parts: This is not a good approach for rotational or cylindrical components, as the time and resource efficiency is low.

Accelerated Tool Wear: Equipment may experience quicker wear because of the increased surface contact when multiple-axis cuts are made, especially with harder metals.

High Initial Preparation: It needs a detailed CAM programming and setup for advanced parts.

Quick and Effective for Round Components: Effective for creating symmetric components such as shafts, rods, and bushings quickly and accurately.

Reduced Operational Cost: Turning centres are cheaper and quicker for bulk production of cylindrical parts.

Cylindrical Surface Restriction: Not effective for flat, angular, or other complex shapes.

Limited Tooling: Tooling, compared to milling, contains fewer varieties and options.

Limited Tool Access: Standard lathe tools may lack the capability to reach certain geometries.

Aerospace Components: CNC is helpful for making high-tolerance brackets, mounts, and structural components.

Medical Equipment Enclosure: Enclosure and structural components are crucial for medical equipment and need to be produced accurately.

Die and Mold making: They are helpful for cavity machining, mold bases, and precision inserts.

Shaft and Axle Parts Manufacturing: Creates long, uniform cylindrical shafts and axles with consistent diameters.

Pipe and Threaded Parts: Best suited for internal and external threaded holes and conical surfaces.

Automotive Rotors and Hubs: Commonly produced for parts such as automotive brake and wheel hubs.

Feature | CNC Milling | CNC Turning |

Motion Type | Rotating tool, fixed part | Rotating part, fixed tool |

Ideal Shapes | Flat and 3D complex parts | Cylindrical and symmetrical |

Axis Configuration | 3 to 5 axes | Typically 2 axes |

Setup Time | Longer setup | Faster setup |

Speed for Rounds | Slower | Much faster |

Design Flexibility | High | Limited to round features |

3-axis and 5-axis machining are both types of CNC milling, but they differ in the rotation of the tool and the workpiece.

In 3-axis machining, the tool moves in 3 linear axes: X, Y, and Z, with the workpiece stationary. In 5-axis machining, the tool or table is capable of tilting or rotating as well, providing an additional 2 degrees of movement—thus, 5 degrees of movement total.

In 3-axis machining, the tool is vertical and moves only in a linear direction, which can only be achieved through rotation. The workpiece is motionless, which means there is only so much geometry that can be fabricated without repositioning.

As for 5-axis machining, it offers access to the workpiece from virtually any angle, as the tool or work table may tilt and rotate. This minimises the number of setups and helps access surfaces that are hard to reach.

Lower Maintenance Cost: 5-axis machines are more costly to set up and maintain.

Effective for Basic Parts: Performs well with planar tasks such as drilling, pocketing, or facing.

Greater Accessibility: Often found in small CNC shops and other workshops due to their simple design.

Figure no 5. 3-axis CNC machining

Greater Time and Error Inaccuracies: Parts need to be repositioned, increasing the chances of time and errors due to multiple setups.

Lower Precision: Greater chance of lower precision for intricate jobs, due to slower production from manual repositioning and increased tool changeovers.

Not Efficient for Deep Cavities: A Greater chance of lower precision, as the machine requires longer tools and increases vibrations.

Reduced Number of Setups: Greater chance of lower machining time, as workpieces are continuously repositioned instead of clamped.

Improved Wear Reduction: Degraded tools are less susceptible to optimal angles, thus improving the remaining usable life of the tools.

Better Surface Finish: Permits smoother finishes for contoured surfaces.

High Initial Investment: Requires expensive machines, advanced software, trained personnel, and sophisticated hardware.

Complex Programming: Skilled CAM designers and advanced simulations are necessary to prevent collisions and product damage.

Not Always Necessary: Simple parts that can be done with 3-axis machining do not justify the costs and complexity of this setup.

Flat Plates and Housings: Best for planar machining of mounting plates and housing covers.

Mold Bases: Utilized for rough machining of cavity pockets and finishing of flat surfaces in the tool and die industries.

Engraving and Signage: Frequently used to engrave logos and shapes on metallic and plastic sheets.

Basic Industrial Parts: Suitable for parts such as blocks, brackets, and other simple fixture components.

5-Axis Machining: Suitable Applications

Aerospace Turbine Blades: Best suited for deep-pocketed, highly contoured components.

Medical Implants: Utilised in complex components such as hip joints, dental, and orthopaedic parts.

Automotive Performance Parts: Aids in achieving optimised, lightweight structures in engines and suspension parts.

Feature | 3-axis Machining | 5-axis Machining |

Degrees of Freedom | X, Y, Z | X, Y, Z + A (rotation), B (tilt) |

Best For | Simple, flat geometries | Complex, multi-surface components |

Setup Time | Longer for complex parts | Minimal due to single-setup machining |

Programming Ease | Easy | Complex and advanced |

Equipment Cost | Lower | Higher |

Surface Finish | Good | Excellent due to optimal tool angles |

CNC milling and CNC routing are both processes that involve the use of a rotating tool to cut and remove material. Although the two share a common base, the machines that perform them differ significantly, mostly because of the materials that they work with, the precision required, and the use case.

A CNC milling machine works with a robust body that holds a cutting tool that can advance in 3 or more linear directions. This makes it possible to shape hard materials with a high degree of accuracy.

A CNC router works faster than a CNC milling machine because it uses a more agile machine. This machine spins a cutter at a high rpm to quickly cut soft materials like wood and foam.

Increased Shock Resistance: CNC milling machines use a robust body. This enables them to better absorb vibration shocks. Thus, CNC milling machines provide better accuracy and dependability when working with hard materials.

Versatility in Processing Materials: Capable of processing hard materials like metals and alloys (steel, aluminium), engineering plastics, as well as softer engineering plastics.

Ability to support robust processes: complex processes, including pocketing, drilling, and contouring, can be performed within a single setup.

Reduced Speed: Hard materials and the precision associated with them increase the amount of time needed for CNC milling compared to other technologies.

Increased Expense: Maintenance and purchase costs for milling machines are higher than those for a router if you make CNC machining processes comparison.

High Cutting Speed: CNC routing is especially effective for softer materials such as wood, plastics and foam as they can be processed quickly.

Low Machine Cost: CNC routers are usually more affordable, making them easy to acquire for new or small workshops and businesses.

Lightweight Setup: Easier to install and operate for small-scale jobs such as installations and relocations for projects.

Less Accurate: CNC routers are less precise due to the lightweight of the frame, making it unsuitable for intricate or precise parts.

More Vibration: This is especially prominent with deeper or denser cuts.

Shorter Tool Life: Tool wear is more pronounced with high spindle speeds and hard materials, leading to a shortened life span of the tool.

Metal Component Manufacturing: In the production of parts such as engine components, molds, or mechanical housings, precision is needed for their fabrication.

Tool and Die Making: Excellent for producing custom dies and fixtures for manufacturing setups.

Aerospace and Medical parts: Great for components needing rigorous strength and precise tolerances.

Woodworking Projects: Ideal for furniture creation, wooden signs, cabinets, and decorative panels.

Foam and Plastic Cutting: Commonly employed in the cutting of packaging foam, acrylic sheets, PVC boards, and foam and sign materials.

Composite Trimming: Helpful in the marine and automotive industries for fibreglass and carbon-fibre parts.

Feature | CNC Milling | CNC Routing |

Machine Rigidity | High | Low |

Core Difference | Made for precision and hard cutting | Built for speed on soft materials |

Suitable Materials | Metals, hard plastics | Wood, soft plastics, foam |

Cutting Speed | Slower | Faster |

Precision Level | Very high | Moderate |

Application Industries | Aerospace, Automotive, Tooling | Sign-making, Furniture, Packaging |

Cost and Setup | Expensive, complex setup | Affordable, easier setup |

Drilling: The creation of a hole in a solid material using a drill bit is referred to as drilling. It is the initial step in the hole-making process.

Boring: Ok, now let’s discuss CNC drilling vs boring. Boring is the process of enlarging a hole using a single-point cutting tool, which improves its cylindrical precision.

Reaming: Now you will be thinking of CNC drilling vs reaming. Ok, reaming is the final step of the process. It smoothens and enlarges a pre-drilled or bored hole to give it a specific dimension and a smooth surface.

Drilling creates the initial hole, while boring aligns and expands the hole, and reaming smoothens the hole to the required exact measurements and surface finish.

It is Fast and Cost-Effective

Drilling is Flexible for All Materials

Ideal for Preceding Operations

It cannot be used when the precision of the hole’s diameter is critical.

Internal walls may be rough.

Bend and curved surfaces can result in the bending of the drill bits.

Takes care of irregularities and misalignments.

Better alignment of the hole into the rotated axis.

Capable of creating multiple-sized holes while using the same tool body.

Excellent for fixing the flaws of the drilled holes.

Cannot originate a hole from nothing

Time to completion is longer than drilling.

Cannot perform in high-speed settings.

The created surfaces can be hole surfaces inward with mirrors.

Tight control of the size of the hole with a precision of Microns.

Best for high volumes for exact hole requirements.

Impossible to operate without a hole.

Sensitive to off alignment.

Single tool restrictions to a set diameter.

Feature | Drilling | Boring | Reaming |

Main Purpose | Hole creation | Hole enlargement and alignment | Hole finishing |

Hole Precision | Low (±0.1 mm typical) | Medium (±0.05 mm typical) | High (±0.01 mm or better) |

Surface Finish | Rough | Improved | Smooth to mirror-like |

Tool Type | Twist drill bit | Single-point boring bar | Multi-edge reamer |

Can Start a Hole | Yes | No | No |

Material Removal Rate | High | Medium | Low |

It is important to comprehend your part’s precise requirements for fabrication before choosing any CNC machining process. This simple flowchart will discuss how to choose cnc machining process in simple steps.

Examining the outline is a good start. For parts that are mostly cylindrical, CNC turning will work well. Complex, prismatic parts that have counters or pockets are best addressed using CNC milling. For cylindrical holes, either drilling, boring, or reaming can be performed depending upon the diameter and finish.

Soft materials such as plastic or wood are best managed using CNC routing. In contrast, hard metals are best milled or ground. Moreover, grinding is best for hardened steels and for ultra-smooth surfaces.

If your design includes tight tolerances with vital fits such as aerospace or medical parts, then those are best addressed with milling or grinding. For general precision, turning and routing are also sufficient.

In terms of the overall production volume, the turning and milling processes are quite efficient when performed automatically. Parts that are needed in single copies or prototypes can be produced quickly with manual machining or routing. This is dependent upon the material type.

Criteria | CNC Milling | CNC Turning | 5-Axis CNC | Drilling | Boring | Reaming |

Part Geometry | Flat, prismatic, complex 3D surfaces | Cylindrical, concentric features | Highly complex, multi-face parts | Simple holes | Enlarged holes | Final hole sizing |

Material Suitability | Metals, plastics, composites | Metals, plastics | Metals, alloys, composites | Metals, plastics | Metals | Metals, some plastics |

Precision | High | Medium to high | Ultra-high | Medium | High | Very high |

Surface Finish | Smooth to very fine | Good | Excellent | Rough to good | Improved over drilling | Excellent |

Tool Access | 3-axis (some limits) | Single-axis | Multi-angle, undercuts possible | Straight line only | Straight line only | Straight line only |

Production Volume | Low to medium | Medium to high | Low to medium | High | Medium | Medium |

Cost | Moderate | Low to moderate | High | Low | Moderate | Moderate |

Typical Use Case | Enclosures, brackets, complex surfaces | Shafts, bushings, round parts | Aerospace parts, medical implants | Hole creation | Hole diameter refinement | Final dimension and surface accuracy |

Still worrying about selecting the right CNC machining process for your project? Simply upload your CAD drawing now, and the engineers at RapidDirect will perform a free process evaluation and provide an instant quote. This guarantees that your part will be fabricated accurately, punctually, and cost-effectively.

Moreover, we offer CNC machining, CNC milling, CNC turning, 5-axis CNC machining, precision machining services, and more. So, when all solutions are available on one reliable platform, then no need to worry anymore. Just contact RapidDirect now!

Alright! So, we saw that each precision machining method has its own distinct advantages and disadvantages. And the selection can only be made according to the type of project requirements. Okay, we tried to provide you with distinct CNC machining processes comparisons, professional advice, and a well-defined structure to support your choice. So, use it to confidently choose the best machining process for your next component. Good luck!

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.