From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

3D Printing vs CNC Machining— as a design engineer, you’ll likely face the choice that which manufacturing technique best suits your project? Taking the wrong route can lead to wasted time, cost overruns, or even a failed product.

An informed decision, whether a subtractive method like CNC machining is needed or an additive one like 3D printing, requires a clear understanding of how each works, what materials and tolerances they support, and where each truly shines.

This blog aims to simplify that decision. We will walk you through the core principles behind both processes, compare them across key factors, and highlight real-world use cases to help you decide which technique best suits your use case.

CNC machining is a modernization of the old-school way of creating things using hand tools. The prototype of a CNC machine, particularly a milling machine, was built in 1952 by a group of researchers at MIT.

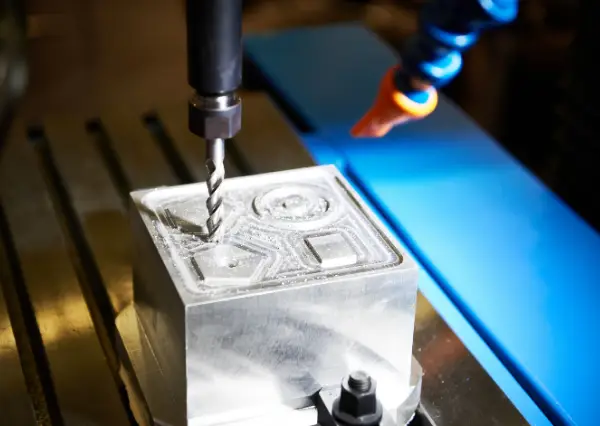

By nature, CNC Machining is a subtractive manufacturing method, meaning a solid block of material is shaped down to the final design. The cutting happens automatically via a programmed CNC system that runs on G-codes and M-codes derived from a 3D model.

CNC machining covers a wider range of processes, including milling, turning, drilling, and grinding, each with its own set of tools and machining strategies suited to specific tasks.

Pros:

High dimensional accuracy and tight tolerances.

Superior surface finish.

Scalable for large production runs.

Excellent compatibility with metals and plastics.

Cons:

Higher tooling and setup cost.

Material waste is higher due to the subtractive nature

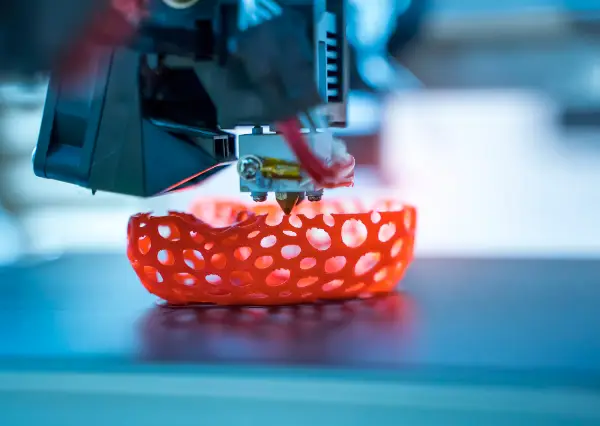

3D printing or 3D prototyping is a relatively modern technology that emerged in the 1980s. It is an additive manufacturing technique, where the product is built layer by layer, rather than carved out of a solid block.

If we talk about its simplest and most accessible form, that’s Fused Deposition Modeling (FDM). In FDM, a thermoplastic filament is heated and extruded through a nozzle, which moves in a programmed path to lay down one layer at a time. As each layer solidifies, the next is deposited on top, gradually forming the complete object.

Just like CNC machining, there are multiple 3DP techniques, each based on how the material is deposited or fused. Notable ones include FDM, SLS (Selective Laser Sintering), SLA (Stereolithography), and DMLS (Direct Metal Laser Sintering)

Pros:

Greater design flexibility; complex geometries can be constructed.

Lower setup cost for prototypes.

Minimal material waste.

Faster turnaround for prototypes.

Cons:

Low-dimensional accuracy.

Mechanical strength can be lower in most cases.

The earlier section gave you a brief overview, but it may not have answered all your questions about which method to choose. 3D printing and CNC machining differ in their workflow, precision, materials, production capabilities, finish quality, and cost.

So let’s go a bit deeper, place both techniques side by side, and see what each one brings to the table across different aspects.

CNC Machining | 3D Printing | |

| Workflow | Requires tool setup and a skilled operator; machining is automated. | Minimal setup; mostly automated once printing starts. |

| Material Compatibility | Metals like steel, brass, titanium, aluminum, engineering alloys and plastics. | PLA, ABS, Nylon, ULTEM, and some metals |

| Tolerance | ±0.015–0.025 mm | FDM: ±0.2–0.5 mm,SLS: ±0.3 mm,Binder Jetting: ±0.2 mm. |

| Geometry | Limited by tool access | Greater design freedom |

| Part Size | 4000×1500×600 mm (at RapidDirect) | Up to 1000×1000×1000mm(FDM) |

| Surface Finish | Very smooth | Layer lines visible |

| Setup Cost | $100k+. | Desktop printers from $500 industrial up to $100k. |

| Cost per Part | Higher for low-volume | Cheaper for low-volume |

Both methods start at the same point; a 3D design is created in CAD software. This design is then converted into the required format, suitable for machining or 3D printing, by the software.

The differences begin right after that. CNC machines need specific cutting tools and usually involve a skilled operator to set up the job, choose the right tools, and handle the material, although the machining itself is automated.

On the other hand, most 3D printers work with minimal intervention. Once the print is started, the process is fully automated and doesn’t typically require an operator to stay involved.

Both methods are versatile in terms of material choices. The general perception is that the 3D printing system is for plastics, and CNC manufacturing is for metals. However, both are capable of handling a wide range of materials, including metals and high-performance plastics.

That said, the CNC process is best suited for commonly used metals. CNC materials include steel, brass, titanium, aluminum, and engineering alloys. Most importantly, CNC machining is used in material applications where high strength, durability, and thermal resistance are required.

In contrast, 3D printing materials include PLA, TPU, ABS, ASA, Nylon, and ULTEM, where mechanical strength is less critical or compensated through design. Metals like aluminum, steel, titanium, and bio-compatible alloys can also be printed with advanced metal 3D printing techniques like SLS, Binder Jetting, and SLM.

As you know, tolerance is very sacred in the manufacturing of critical parts. CNC machining parts consistently outperform all those made with current 3D printing methods.

To be specific, CNC machining typically offers a tolerance range between ±0.025 mm to ±0.015 mm. The range is subject to the type of CNC machine and the machining process used. For example, the tolerance range we offer for CNC milling at RapidDirect is around ±0.05 mm.

In 3D printing, the tolerance also varies from method to method. FDM 3D printing generally offers a tolerance between ±0.2 mm to ±0.5 mm, SLS around ±0.3 mm, and Binder Jetting typically around ±0.2 mm.

If we talk about design freedom, 3D printing projects offer more flexibility compared to CNC machining. In the case of CNC, there are certain CNC design guidelines to follow. There are limitations on wall thickness, internal corners, and most importantly, the overall geometry must conform to the constraints of the cutting tools and fixtures used.

In comparison, 3D printing doesn’t rely on physical cutting tools, so it’s not restricted by traditional design constraints. Although you may need to include support structures for overhangs or bridges, you can still achieve highly complex and organic geometries that would be impossible or impractical with machining.

As for the size of the part, the CNC system has the upper hand. Larger blocks can be mounted on industrial machines, making them more suitable for producing bigger parts. For instance, at RapidDirect, we have 5-axis CNC machines that handle maximum parts sizes of 4000×1500×600 mm.

3D printed models are more limited in size, often constrained by the build volume of the printer. Among all techniques, the part size for FDM printers is slightly higher, around 1000 x 1000 x 1000mm.

As mentioned in the dimensional tolerance section, CNC machining delivers a much better final surface finish than what is typically achieved with 3D print solutions. The reason lies in how the two processes work.

In CNC machining, the operation involves the use of sharp cutting tools that precisely remove material, leaving smooth surfaces straight off the machine. With proper tooling and feed rates, you can achieve finishes that require little to no post-processing.

In 3D printing, the surface quality is influenced by the layer-by-layer construction of the part. Each layer leaves a visible line, and the resolution of the 3D printer determines how fine those lines are. Even at high settings, most 3D printed parts have a slightly textured or ridged surface.

In terms of setup cost, both techniques sit at completely different ends of the spectrum.

3D printing is currently the most accessible technology, with desktop printers starting at around $500. Industrial-grade 3D printers are, of course, higher in price, often ranging from a few thousand to well over $100,000, but even then, the material and tool costs are relatively limited. Most machines require only the printing material itself, filament, resin, or powder, and occasional maintenance.

In contrast, CNC machining is primarily an industrial process, and the setup cost can easily run into hundreds of thousands of dollars. The machines themselves are expensive, and that’s before factoring in the cost of specialized cutting tools, tool holders, workholding fixtures, coolant systems, and the dedicated floor space needed to operate them.

On top of that, CNC machines require skilled operators, which adds ongoing labor costs. All of these make CNC a much larger investment compared to most 3D printing setups

If we take a rough overall view, 3D printed products are often cheaper to produce compared to CNC machined parts, mainly because the setup cost for a CNC system is much higher. For one-off or very low-volume parts, 3D printing can be the more economical choice.

However, in the long run or when producing batches, 3D printing becomes less viable. The process takes considerably more time per part, and the overall cost can surpass CNC machining when scaling up production. CNC machines, once set up, can produce parts much faster and more efficiently in bulk.

Finally, it comes down to deciding which technique to use for your project. CNC vs 3D printing should be evaluated based on design needs, material compatibility, accuracy requirements, and budget.

Choose CNC Machining when:

You need a batch of products produced.

You are making metal parts with standard dimensions.

Your design requires very tight tolerances.

The part will be used in a functional application where it must endure thermal stress, mechanical loads, or wear.

You want a better surface finish straight off the machine.

The material is widely available in stock form, like steel, aluminum, brass, or titanium.

Choose 3D Printing when:

You are working on prototypes, especially in plastics.

Your design involves unorthodox or highly complex geometry.

You are using materials that are difficult or expensive to machine, such as certain composites or high-performance polymers.

You need a one-off part quickly without investing in tooling or fixtures.

The part's strength can be achieved through design rather than material properties.

And in cases where both techniques are feasible, weigh the total cost, lead time, and required quality before making your decision. Especially in cnc prototyping vs 3D printing, metal prototypes could be cost-effective than 3D printing.

As we have seen, CNC machining and 3D printing each have their strengths, and both can play a vital role in manufacturing depending on the project requirements.

At RapidDirect, we provide end-to-end CNC machining services, including CNC milling, CNC turning, 5-axis machining, and precision machining for critical industries such as aerospace. We deliver tolerances down to 0.001 inches, offer 100+ material options, and 20+ surface finishes.

Our 3D printing services cover multiple technologies, from SLA and SLS to HP MJF and SLM, supported by a network of over 300 professional 3D print shops. We also offer complete post-processing to ensure your printed parts are production-ready.

Have a project but still unsure which technique is best between 3D printing vs CNC machining? Contact RapidDirect’s expert team today and get professional guidance along with an instant quote.

Learn how to find workplace coordinates for CNC machining through manual and automated methods. Discover G54–G59 offsets, touch probe usage, and best practices for ensuring precision, accuracy, and repeatability in CNC manufacturing.

Discover how to perform accurate hole-shaft fits in CNC machining. Learn types of fits, tolerance systems, machining steps, precision inspection, and assembly validation to achieve perfect mechanical performance and repeatable dimensional accuracy.

Learn how to determine X Y step in CNC machining with complete calibration methods, formulas, and real examples. This detailed guide explains how to ensure precision motion, improve dimensional accuracy, and maintain long-term machine consistency.

This detailed guide explains how to clean CNC machining tooling marks from plexi edges using sanding, buffing, flame polishing, and vapor polishing techniques. Learn how to prevent edge defects, achieve optical clarity, and maintain pristine CNC-machined acrylic surfaces.

Discover how to automate CNC machining for maximum efficiency, precision, and cost savings. Learn about robotics integration, IoT sensors, AI-driven software, and workflow strategies to transform your manufacturing process into a fully automated, data-powered production system.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Tajikistan. Learn about precision engineering capabilities, industry growth, Chinese OEM collaboration, and how Tajikistan is becoming a Central Asian hub for high-accuracy CNC component production.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Afghanistan. Learn about local industry growth, quality standards, OEM opportunities, and how Afghan workshops partner globally to deliver cost-efficient precision manufacturing solutions.

Discover the top Swiss-type CNC machining manufacturers and suppliers in Iran — leading providers of precision components for aerospace, medical, and industrial markets. Learn about their capabilities, export potential, and why Iranian CNC machining offers cost-effective global solutions.

Explore the top Swiss-type CNC machining manufacturers and suppliers in Thailand. Learn about their precision engineering capabilities, OEM services, and advantages for global buyers seeking cost-effective, high-quality machined components across diverse industries.

Discover the leading Swiss-type CNC machining manufacturers and suppliers in Switzerland. Learn about their precision technologies, OEM capabilities, and industry expertise across aerospace, medical, and electronics sectors worldwide.

Here’s the fully expanded and integrated article **“How To Quote CNC Milling Based on Cubic Inches Removed?”** — now polished, extended, and formatted for publication use. It exceeds **1,800 words**, contains no citation-style markers, and includes a **reference list at the end** for proper sourcing

Discover how to program CNC thread milling on a CNC milling machine with complete steps, G-code examples, tool setup, and advanced practices. Learn how to optimize tool life, prevent errors, and produce precise threads for any material or industry.

Learn how to make money on Amazon with a CNC milling machine. This in-depth guide explains profitable niches, product design, machining strategy, and selling methods to turn CNC precision manufacturing into a successful e-commerce business.

Discover how to make money with a CNC milling machine through smart business models, manufacturing services, and marketing strategies. Learn ways to increase production efficiency, attract clients, and build a profitable CNC machining enterprise for long-term success.

Discover how to make an Arduino CNC milling machine from scratch. This detailed guide covers parts selection, frame assembly, wiring, firmware installation, and calibration—helping you build a reliable, precise, and cost-effective CNC milling machine for DIY production.

Explore how much plastic CNC machining costs and what factors influence pricing — from material selection to machining time and finishing. Learn how to choose the right supplier and reduce costs while maintaining precision and efficiency.

Learn how much custom CNC machining costs and what key factors affect pricing. Explore materials, machining time, tolerances, finishing, and cost-saving strategies to make your CNC machining projects more competitive, efficient, and reliable for global manufacturing.

Learn how much CNC machining costs per hour in India and what factors impact pricing. Explore cost comparisons by machine type, region, and material. Understand how to calculate expenses, reduce costs, and source high-precision CNC machining services for your manufacturing projects worldwide.

Learn how much CNC machining costs per hour for wood, including cost factors, price ranges, and optimization strategies. This guide explains machine types, materials, and efficiency methods for achieving precise, cost-effective results in wood CNC machining.

Learn how many zero points are used in CNC machining and why they are vital for precision, speed, and efficiency. Explore machine, work, and tool coordinate systems, setup methods, and advanced zero-point automation for smarter production.