From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-10 Origin: Site

Content Menu

● Key Differences Between CNC Turning and Milling

● Applications Across Industries

● Advantages of CNC Turning and Milling

● Common Challenges in CNC Machining

● Quality Control and Inspection Techniques

● Integration of CNC Turning and Milling (Turn-Mill Centers)

>> Benefits of Turn-Mill Integration

● Technological Advancements in CNC Machining

● Environmental Considerations

● FAQ

>> 1. What materials can be machined using CNC turning and milling?

>> 2. How accurate are CNC machines?

>> 3. What is the difference between 3-axis and 5-axis milling?

>> 4. How does CNC programming work?

>> 5. What are common defects in CNC machining?

CNC turning and milling are two of the most vital machining processes in modern manufacturing. As pillars of Computer Numerical Control (CNC) technology, they play an essential role in producing precision-engineered components for industries ranging from aerospace to medical devices. Both processes rely on programmed computer commands to control the motion, speed, and feed of cutting tools. Although they share a similar foundation, the way the material is shaped and the types of parts produced are quite distinct.

Understanding how CNC turning and milling work—and the conditions in which each is most effective—is fundamental for manufacturers who want to optimize efficiency, accuracy, and production costs. This article explores each process in depth, highlighting their principles, differences, applications, and integration in modern industry.

CNC machining represents the automation of traditional manufacturing methods using digital instructions. It replaces manual handwheels and levers with software-driven precision, ensuring high repeatability and minimal human error.

At its core, a CNC machine interprets a digital design file (generated through Computer-Aided Design, or CAD) and translates it into machine-readable G-code via Computer-Aided Manufacturing (CAM). These codes instruct the machine on tool paths, spindle speeds, feed rates, and depth of cuts.

The entire process consists of several stages:

1. Designing the part – Engineers create a 3D model using CAD software.

2. Tool path generation – CAM software defines the most efficient cutting sequence.

3. Simulation and verification – The digital model is tested for accuracy and potential tool collisions.

4. Machining – The CNC machine executes commands to produce the physical component.

5. Inspection – The finished part is measured for dimensional accuracy and surface quality.

This advanced workflow enables CNC machining to handle a variety of operations such as drilling, boring, tapping, shaping, turning, and milling—all aimed at achieving tight tolerances and high-quality finishes.

CNC turning is a subtractive process in which a metal or plastic workpiece rotates on a spindle while a stationary cutting tool removes material to form the desired shape. The rotation speed, tool feed, and depth of cut are all controlled digitally, allowing for precise machining of cylindrical or conical parts.

The process begins with a cylindrical workpiece clamped securely into the chuck of a CNC lathe. Once the spindle rotates, the cutting tool—mounted on a programmable turret—moves along one or more axes to remove material. The operator defines exact coordinates for each toolpath, allowing for complex geometries like tapers, grooves, contours, or threads.

Common turning operations include:

- Facing: Flattening the end of a workpiece to create a smooth surface.

- Taper turning: Producing conical shapes by varying the tool's cutting angle.

- Grooving: Cutting narrow recesses or channels.

- Threading: Forming internal or external threads on cylindrical surfaces.

- Drilling and boring: Creating or enlarging holes along the rotational axis.

CNC turning machines come in several configurations, including 2-axis lathes, 3-axis lathes, and multi-axis turning centers. Modern CNC Swiss lathes allow micromachining of tiny precision parts for medical and electronics applications.

In contrast to turning, CNC milling involves a stationary workpiece and a rotating cutting tool. The spindle spins the tool at high speed while the table holding the workpiece moves in multiple axes. This enables the machine to remove material from different directions, making it ideal for creating complex shapes and 3D surfaces.

A typical milling operation begins with securing a solid block of material onto the machine table. Depending on the part design, milling can occur in 3-axis, 4-axis, or 5-axis configurations:

- 3-axis milling: The most common, allowing movement along the X, Y, and Z axes.

- 4-axis milling: Adds a rotational movement, enabling cutting around cylindrical surfaces.

- 5-axis milling: Provides full freedom of movement, allowing simultaneous multi-directional cutting for highly intricate components such as turbine blades or orthopedic implants.

CNC milling machines perform various operations like face milling, contour milling, slotting, pocketing, and engravings. With tool changers and automated pallets, modern milling centers can complete multiple machining operations in one setup, drastically improving throughput and precision.

While both processes shape materials through controlled cutting, they fundamentally differ in mechanics and application scope.

| Feature | CNC Turning | CNC Milling |

|---|---|---|

| Primary motion | Workpiece rotates | Cutting tool rotates |

| Typical shapes | Cylindrical, conical, or symmetrical parts | Flat, angular, or irregular shapes |

| Machine type | CNC lathe or turning center | CNC milling machine or machining center |

| Cutting axes | Usually 2 to 4 | Typically 3 to 5 |

| Common materials | Metals, plastics, composites | Broad range: metals, polymers, wood, ceramics |

| Examples | Shafts, pins, bushings, screws, bearings | Brackets, molds, housings, engine blocks |

In practice, CNC turning produces components like gear shafts and valve stems, whereas CNC milling handles tasks like machining mold cavities or cutting engine cylinder heads. For hybrid shapes, machinists often combine both methods in one workflow.

CNC turning and milling are indispensable across nearly every manufacturing discipline:

- Aerospace Manufacturing: Precision parts like turbine blades, landing gear pins, and engine rotors.

- Automotive Engineering: Axles, pistons, camshafts, brake components, and engine mounts.

- Medical Devices: Prosthetics, implants, and surgical tools requiring biocompatible precision.

- Defense and Firearms: Components for weapon assemblies and precision targeting systems.

- Consumer Electronics: Small connectors, aluminum housings, and cooling components.

- Energy Sector: Pump bodies, flow control valves, and drilling components.

Their consistent accuracy ensures high-performance standards even under extreme temperature, pressure, or load conditions.

The use of CNC automation offers numerous advantages over manual machining or conventional production methods:

1. Superior Accuracy: Digital control maintains tolerances within microns.

2. Repeatability: Consistent replication across thousands of identical parts.

3. Enhanced Productivity: Continuous operation with minimal operator intervention.

4. Material Versatility: Suitable for almost any machinable material.

5. Complex Geometry Capability: Achieves designs impossible with manual machining.

6. Reduced Human Error: Automated calibration prevents dimensional deviations.

7. Integration with CAD/CAM: Direct design-to-production workflow eliminates intermediate steps.

Such qualities make CNC technology foundational to smart factories and precision engineering workflows.

Even with automation, CNC machining encounters several practical challenges:

- Setup and programming time: Initial setup and code generation can be labor-intensive for complex parts.

- Tool wear: Continuous operation leads to tool degradation, affecting surface quality.

- Vibration and chatter: Excessive cutting force or poor clamping can cause instability.

- Power and cost demands: High-speed spindles consume significant energy.

- Deburring and finishing: Post-machining processes may be needed to remove sharp edges.

Many modern CNC machines incorporate smart sensors, load monitoring systems, and AI-based optimization to predict tool wear and maintain stable cutting conditions.

Accuracy in CNC turning and milling is verified through rigorous inspection standards. Processes typically use:

- Coordinate Measuring Machines (CMM): Automated systems that scan the part's geometry.

- Laser Scanners and Vision Systems: Capture surface details and verify dimensions without contact.

- Surface Roughness Testers: Measure finish quality for friction-sensitive parts.

- Calibration Software: Monitors machine alignment and tool offset data.

These quality control measures ensure that parts meet stringent ISO or AS9100 standards required in high-regulation sectors.

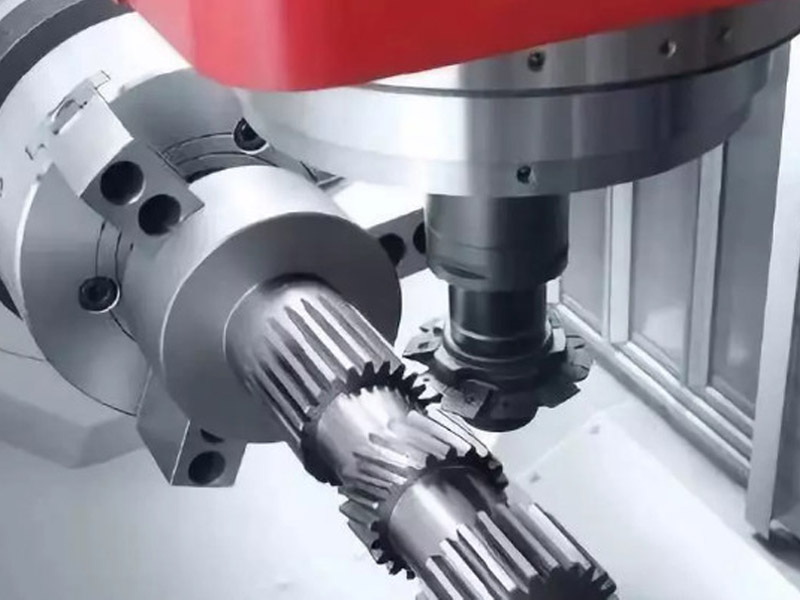

Modern manufacturing often combines turning and milling into hybrid CNC Turn-Mill Centers, enabling both operations on a single machine. This approach reduces downtime, eliminates re-clamping errors, and enhances overall efficiency.

- One-setup machining: Reduces setup time and workpiece repositioning.

- Higher precision: Minimizes dimensional misalignment between turned and milled features.

- Cost efficiency: Shortens production cycles and labor costs.

- Complex machining: Capable of simultaneous operations for intricate parts.

Future manufacturing systems are trending toward full automation, combining robotic part handling, automated tool changers, and live data monitoring for predictive maintenance.

Advances in CNC technology continually push boundaries in precision engineering. Some notable innovations include:

- 5-axis simultaneous machining: Allows cutting from any direction with superior surface quality.

- Tool condition monitoring (TCM): Predicts tool life using onboard sensors.

- Hybrid manufacturing: Merges additive (3D printing) and subtractive (CNC) methods.

- Digital twins: Virtual models that simulate machine performance in real time.

- Cloud-based CNC control: Enables remote programming and monitoring across global facilities.

Such advancements lower production costs, minimize waste, and allow custom manufacturing at unprecedented speed.

Modern CNC machining facilities increasingly focus on sustainability. Key efforts include:

- Coolant recycling systems that reduce fluid waste.

- Chip reclamation equipment that recovers valuable metal shavings.

- Energy-efficient motors for spindle and feed drives.

- Software optimization to minimize idle time and tool movement.

Sustainable CNC operations not only reduce environmental impact but also improve profitability by lowering material and energy consumption.

CNC turning and milling form the backbone of today's precision manufacturing. While turning is specialized for cylindrical components, milling handles flat and complex geometries. Together, they enable manufacturers to produce intricate designs with unmatched speed, repeatability, and accuracy.

With the integration of digital control, smart sensors, and hybrid Turn-Mill systems, CNC machining continues to evolve into a cornerstone of Industry 4.0—where quality, efficiency, and intelligence converge to reshape global production.

Both processes handle metals like aluminum, stainless steel, and titanium, as well as plastics such as nylon and polycarbonate. Material choice depends on required strength, durability, and cost.

Modern CNC machines achieve tolerances as fine as ±0.001 mm, enabling applications where dimensional precision is critical, such as aerospace and medical implants.

3-axis milling uses linear movements along X, Y, and Z axes, while 5-axis milling adds two rotational axes, allowing complex multi-directional cutting without repositioning the part.

Programming converts CAD models into G-code through CAM software. The G-code defines tool motions, spindle speeds, and feed rates based on the part geometry and machining strategy.

Typical issues include tool wear, burr formation, improper surface roughness, and dimensional drift. These can be mitigated through proper tool maintenance, coolant application, and regular calibration.

Explore the top 10 Prototype CNC Machining Manufacturers in China. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd., this detailed guide covers their strengths, capabilities, and why Chinese CNC machining companies lead in global innovation and precision manufacturing.

Discover the Top 10 Precision CNC Machining Manufacturers in China, highlighting their strengths, technologies, and OEM capabilities. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd. as a leader, this guide helps global buyers find reliable CNC partners for precision engineering projects.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.

Learn how to post 3D printing services professionally with this comprehensive guide. Discover key steps for building an online presence, optimizing listings, managing orders, pricing smartly, and staying competitive in the fast-growing 3D printing market.

This extended guide explains how to market a 3D printing service through branding, SEO, content creation, social media, partnerships, and client experience. It provides actionable marketing strategies to build trust, improve visibility, and drive growth in a competitive 3D printing industry.

This comprehensive guide explains how to compare 3D printing services by analyzing key aspects such as technology options, materials, quality control, pricing transparency, delivery time, scalability, and security. It helps readers choose reliable providers for both prototypes and production parts.

An in-depth guide to choosing the right 3D printing service. Learn to evaluate technologies, materials, quality standards, and pricing. Perfect for engineers, designers, and entrepreneurs seeking reliable, precise, and cost-effective 3D printing solutions.

Discover how to effectively advertise 3D printing services using SEO, social media, paid campaigns, and branding. This comprehensive guide explains proven marketing strategies to grow your audience, attract clients, and build authority in the evolving 3D printing industry.

This in-depth article explains what defines the best CNC milling machine, highlighting critical technical features, top brands, maintenance tips, and emerging smart manufacturing trends. It concludes with expert advice and FAQs, guiding readers toward the ideal CNC solution for their needs.

This detailed article explores CNC turning and milling processes, explaining their working principles, differences, advantages, and modern applications. It examines recent technological innovations, environmental aspects, and integration trends shaping precision manufacturing in the Industry 4.0 era.

CNC milling is a computer-controlled machining process that creates precise, complex parts from metal or plastic. Used across industries like aerospace, medical, and automotive, it offers high precision, consistency, and adaptability for both prototypes and large-scale manufacturing.

Explore the technology behind 5-axis CNC milling machines, including their operation, types, advantages, and industrial uses. Discover how multi-axis control enhances precision, reduces setup time, and drives innovation in aerospace, automotive, and manufacturing industries.

CNC milling combines computer precision and mechanical control to produce complex, high-accuracy components. Learn how CNC milling works, machine types, materials, advantages, and applications across industries. Includes detailed FAQs exploring its accuracy and future potential.