From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-10 Origin: Site

Content Menu

● What Is a 5 Axis CNC Milling Machine?

>> The Concept Behind Multi-Axis Machining

● How Does a 5 Axis CNC Milling Machine Work?

● Types of 5 Axis CNC Milling Machines

>> 3. Hybrid or Double-Rotary Systems

● Advantages of 5 Axis CNC Milling

>> 4. Optimized Tool Performance

>> 5. Superior Design Flexibility

● Applications of 5 Axis CNC Milling Machines

● Key Components of a 5 Axis CNC Milling Machine

● Materials Commonly Machined with 5 Axis Technology

● Factors to Consider When Choosing a 5 Axis CNC Machine

● Automation and Smart Manufacturing Integration

● The Future of 5 Axis CNC Machining

● FAQs

>> 1. What are the main differences between 3-axis and 5-axis CNC milling?

>> 2. Is a 5-axis machine cost-effective for small production runs?

>> 3. Which industries depend most on 5-axis machining?

>> 4. What software supports 5-axis programming?

>> 5. How do you ensure long-term performance of a 5-axis CNC machine?

In the era of Industry 4.0, high-precision manufacturing plays a crucial role in sectors ranging from aerospace and automotive to healthcare and energy. Companies are continually seeking ways to produce complex parts faster, with higher accuracy and minimal waste. Among the most sophisticated innovations reshaping modern machining is the 5-axis CNC milling machine.

Unlike traditional equipment, the 5-axis machine can move cutting tools along five different paths simultaneously, allowing for the fabrication of intricate geometries in a single operation. This ability eliminates many conventional production constraints and provides a level of productivity once deemed impossible. The following sections explore how this technology works, what makes it so powerful, and how it continues to revolutionize precision machining worldwide.

A 5-axis CNC milling machine is a computer numerical control system capable of moving tools or workpieces along five independent axes at once. The first three axes—X, Y, and Z—control linear motion, just like in standard milling. However, two additional rotational axes—commonly referred to as the A and B or C axes—provide tilting and rotating capabilities.

This combination allows the cutting tool to approach the material from virtually any direction, minimizing repositioning and maximizing efficiency. The “5-axis” designation does not simply refer to five directions of movement; it represents five coordinates under simultaneous and continuous control, managed by the CNC system's servomechanism.

In a 3-axis environment, a machinist must manually reposition the part multiple times to reach difficult angles. Each setup introduces alignment errors and consumes valuable time. By contrast, a 5-axis machine automatically rotates the part or the cutting head, ensuring that even complex contours are processed in one smooth operation. This is particularly essential for parts like turbine blades or orthopedic implants, where precision curvature determines function.

At its core, a CNC milling process involves removing material from a solid block, known as a workpiece, using a rotating cutting tool. In a 5-axis system, both the workpiece and the tool can move dynamically under computer control, enabling continuous cutting along complex surfaces.

The process begins in CAD (Computer-Aided Design) software, where an engineer designs a 3D model of the desired part. This digital model is then transferred to CAM (Computer-Aided Manufacturing) software, which analyzes the geometry and generates toolpaths. These instructions are converted into G-Code, the CNC machine's programming language, dictating every movement the machine must execute.

CAM software also accounts for parameters like cutting speed, tool diameter, feed rate, and depth of cut. The high-precision servomotors within the CNC system translate these data points into smooth, simultaneous movements across all five axes.

In operation, the linear axes (X, Y, Z) determine the forward, backward, up, and down positioning of the tool, while the rotational axes (A and B or C) enable angular orientation. Depending on machine configuration, either the spindle tilts or the table rotates. Sensors and feedback systems ensure that the machine's movements remain synchronized with micron-level precision.

The design of a 5-axis machine determines its performance, capacity, and suitable applications. Two of the most common designs dominate the market:

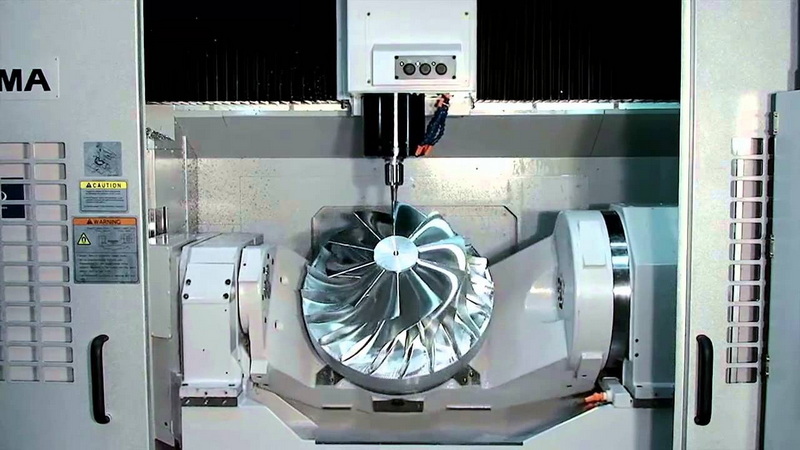

In a trunnion-style configuration, the worktable itself tilts and rotates, typically around the A and C axes. The spindle remains fixed in a vertical orientation. This design provides exceptional rigidity, making it ideal for heavy materials like titanium or steel. Trunnion machines are commonly used in aerospace and automotive sectors, where structural integrity and strength are critical.

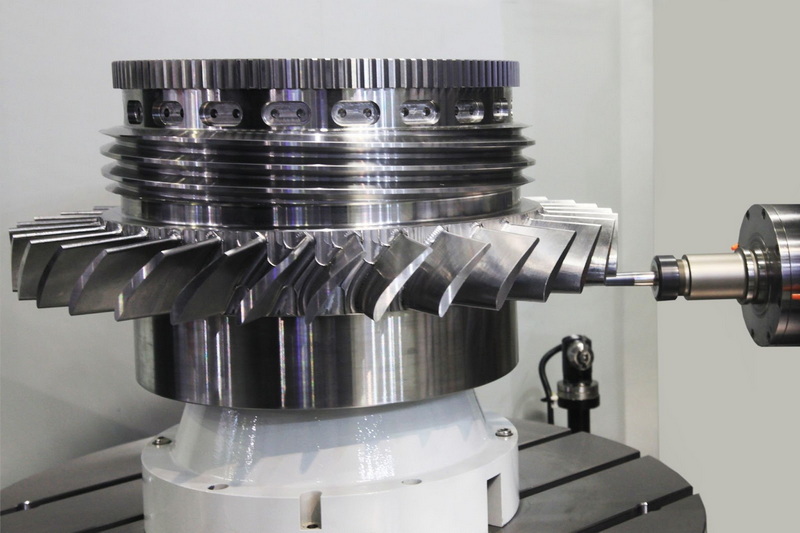

A swivel-head machine differs in that the spindle (cutting head) itself moves around the rotational axes, while the table stays stationary. This structure provides a larger working envelope, enabling the machining of bigger components. It also simplifies fixture design because the workpiece does not need to be repositioned or re-clamped.

Some modern machine tools combine both trunnion and swivel-head features to maximize flexibility. These systems offer improved reach and precision and adapt easily to diverse manufacturing requirements.

The transition from a 3- or 4-axis setup to a 5-axis system dramatically enhances performance metrics across several dimensions.

Since 5-axis machining enables all operations to occur in a single clamping, manual repositioning is nearly eliminated. This not only reduces cycle time but also enhances process reliability.

Each additional setup introduces potential alignment errors. By minimizing human adjustments, dimensional tolerances improve drastically, resulting in components that precisely match design intent.

Smooth, continuous paths maintain consistent tool pressure and avoid abrupt direction changes. As a result, parts emerge with exceptional surface finishes, reducing the need for polishing or secondary operations.

Adjusting the approach angle ensures that cutting tools maintain the ideal contact with the workpiece. This prevents excessive wear, overheating, and chatter, leading to extended tool life and lower operating costs.

Engineers can create imaginative, curved geometries that would have been nearly impossible to produce using conventional milling. This freedom fosters innovation in product design, lightweight structures, and ergonomic components.

The versatility of 5-axis machining expands its utility across multiple industries where exceptional precision and geometry control are demanded.

- Aerospace Engineering: Aircraft turbines, jet engine housings, and airframe structures require smooth aerodynamic contours.

- Automotive Industry: 5-axis milling is critical for high-performance engine parts, transmission housings, and complex molds.

- Medical Manufacturing: Custom implants, bone plates, and surgical tools are produced with organic, patient-specific shapes.

- Energy and Power Generation: Used for machining turbines, rotors, and compressor components that must meet exacting tolerances.

- Robotics and Electronics: Precision-cast parts, custom housings, and heat sinks benefit from the compact accuracy of this technology.

A complete 5-axis system integrates numerous high-performance components working in harmony.

- Spindle Unit: The power source driving the cutting tool; defined by torque, speed, and power ratings.

- Rotary Axes: Mechanisms enabling tilt and rotation, often supported by precision rotary tables or trunnions.

- Tool Changer: Automated magazines allow rapid exchange between multiple tools during machining.

- Controller and CNC Unit: The computational brain that processes code and manages coordinated motion control.

- Feedback Sensors: Encoders and resolvers monitor axis positions for ultra-fine accuracy.

- Coolant and Chip Management System: Maintain temperature and cleanliness, ensuring consistent quality and longer tool life.

5-axis CNC milling machines handle nearly all common engineering materials due to their dynamic adaptability.

- Metals: Aluminum, stainless steel, titanium, and magnesium are frequently used in aerospace and automotive industries.

- Composites: Carbon fiber composites are efficiently sculpted using specialized cutters and controlled feed rates.

- Plastics: Engineering polymers and high-grade plastics are machined into precise prototypes and components.

- Exotic Alloys: Nickel-based superalloys and Inconel used in high-temperature environments are precisely milled without distortion.

Selecting the right machine depends on balancing design complexity, accuracy, and budget.

1. Workpiece Size and Geometry: Ensure the milling area and rotary clearance fit the part dimensions.

2. Machine Configuration: Trunnion or swivel-head configurations each offer unique mechanical advantages.

3. Axis Travel and Speed: Longer travel and higher rotational speeds increase flexibility but also cost.

4. Control System Compatibility: Verify software support for multi-axis CAM operations.

5. After-Sales Support: Reliable training, maintenance, and spare parts availability are critical to sustainable performance.

Despite their advantages, 5-axis machines involve some trade-offs.

- Cost Investment: Purchase price and installation costs can be significantly higher than standard machines.

- Advanced Skill Requirements: Operators must be trained in 3D modeling and CAM programming.

- Complex Programming: Incorrect toolpaths may cause collisions or gouging.

- Maintenance Demand: More moving parts equal higher maintenance frequency.

- Initial Setup Time: Tool calibration and fixture setup for new parts require expertise.

Today's 5-axis CNC systems increasingly integrate with Industry 4.0 principles. Technologies such as IoT connectivity, adaptive control, and AI-based optimization enable predictive maintenance and real-time quality monitoring. Hybrid machines now combine additive manufacturing (3D printing) with 5-axis milling to produce semi-finished parts that can be machined to final precision.

As automation develops, these machines are forming the foundation of smart factories capable of continuous production with minimal supervision.

The evolution of 5-axis machining focuses on smarter, faster, and more sustainable processes. Developments in high-speed spindles, lightweight materials, and digital twins enhance performance predictability. Software improvements continue to simplify CAM programming and collision detection.

With greener manufacturing initiatives taking center stage, future 5-axis systems will likely emphasize energy efficiency, recycled material handling, and enhanced AI-driven adaptive machining strategies. As digitalization continues, this technology will remain indispensable for innovation-driven industries.

The 5-axis CNC milling machine represents the pinnacle of machining technology—combining precision, efficiency, and ingenuity into a single platform. Its ability to move along five simultaneous paths gives manufacturers the flexibility to produce intricate designs that were once time-consuming or impossible to make. Although it demands higher initial investment, skilled operation, and careful maintenance, the payoff comes through extraordinary accuracy, shorter production cycles, and nearly limitless design freedom.

As industries embrace automation and smart manufacturing, 5-axis CNC machines will continue redefining what is achievable in modern production, serving as a bridge between creativity and technology.

A 3-axis system moves in linear directions only (X, Y, Z), while a 5-axis machine adds two rotational axes—enabling angled adjustments and continuous motion to create complex contours without multiple setups.

Yes, for high-value or intricate parts, a 5-axis system reduces setup time, improves accuracy, and lowers rework costs, often compensating for its initial expense.

Industries such as aerospace, automotive, medical device manufacturing, robotics, and energy sectors rely heavily on 5-axis milling for their complex, high-tolerance components.

Commonly used software includes Siemens NX, Mastercam, Fusion 360, CATIA, and SolidCAM—each providing advanced simulation features to prevent collisions and optimize toolpaths.

Regular alignment calibration, lubrication, tool balancing, monitoring spindle temperature, and keeping software updated ensure longevity and consistent precision.

Explore the top 10 Prototype CNC Machining Manufacturers in China. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd., this detailed guide covers their strengths, capabilities, and why Chinese CNC machining companies lead in global innovation and precision manufacturing.

Discover the Top 10 Precision CNC Machining Manufacturers in China, highlighting their strengths, technologies, and OEM capabilities. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd. as a leader, this guide helps global buyers find reliable CNC partners for precision engineering projects.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.

Learn how to post 3D printing services professionally with this comprehensive guide. Discover key steps for building an online presence, optimizing listings, managing orders, pricing smartly, and staying competitive in the fast-growing 3D printing market.

This extended guide explains how to market a 3D printing service through branding, SEO, content creation, social media, partnerships, and client experience. It provides actionable marketing strategies to build trust, improve visibility, and drive growth in a competitive 3D printing industry.

This comprehensive guide explains how to compare 3D printing services by analyzing key aspects such as technology options, materials, quality control, pricing transparency, delivery time, scalability, and security. It helps readers choose reliable providers for both prototypes and production parts.

An in-depth guide to choosing the right 3D printing service. Learn to evaluate technologies, materials, quality standards, and pricing. Perfect for engineers, designers, and entrepreneurs seeking reliable, precise, and cost-effective 3D printing solutions.

Discover how to effectively advertise 3D printing services using SEO, social media, paid campaigns, and branding. This comprehensive guide explains proven marketing strategies to grow your audience, attract clients, and build authority in the evolving 3D printing industry.

This in-depth article explains what defines the best CNC milling machine, highlighting critical technical features, top brands, maintenance tips, and emerging smart manufacturing trends. It concludes with expert advice and FAQs, guiding readers toward the ideal CNC solution for their needs.

This detailed article explores CNC turning and milling processes, explaining their working principles, differences, advantages, and modern applications. It examines recent technological innovations, environmental aspects, and integration trends shaping precision manufacturing in the Industry 4.0 era.

CNC milling is a computer-controlled machining process that creates precise, complex parts from metal or plastic. Used across industries like aerospace, medical, and automotive, it offers high precision, consistency, and adaptability for both prototypes and large-scale manufacturing.

Explore the technology behind 5-axis CNC milling machines, including their operation, types, advantages, and industrial uses. Discover how multi-axis control enhances precision, reduces setup time, and drives innovation in aerospace, automotive, and manufacturing industries.

CNC milling combines computer precision and mechanical control to produce complex, high-accuracy components. Learn how CNC milling works, machine types, materials, advantages, and applications across industries. Includes detailed FAQs exploring its accuracy and future potential.