From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-13 Origin: Site

Content Menu

● 1. Shenzhen Feifan Hardware & Electronics Co., Ltd.

● 2. WayKen Rapid Manufacturing

● 4. PTJ Precision Hardware Co., Ltd.

● 6. Chengdu Seadweer Precision Machinery Co., Ltd.

● 8. Mingfeng Precision Manufacturing Co., Ltd.

● 9. Runsom Precision Co., Ltd.

● The Growing Role of Chinese Custom CNC Machining Manufacturers

● Frequently Asked Questions (FAQ)

>> 1. What makes Custom CNC Machining Manufacturers in China stand out globally?

>> 2. Which industries benefit most from CNC machining services?

>> 3. How can I verify a manufacturer's quality assurance process?

>> 4. What materials do Chinese CNC manufacturers typically handle?

>> 5. Can Custom CNC Machining Manufacturers offer both prototypes and mass production?

>> 6. How do manufacturers manage confidentiality and intellectual property?

>> 7. What's the typical delivery time?

>> 8. How can foreign clients communicate efficiently with Chinese manufacturers?

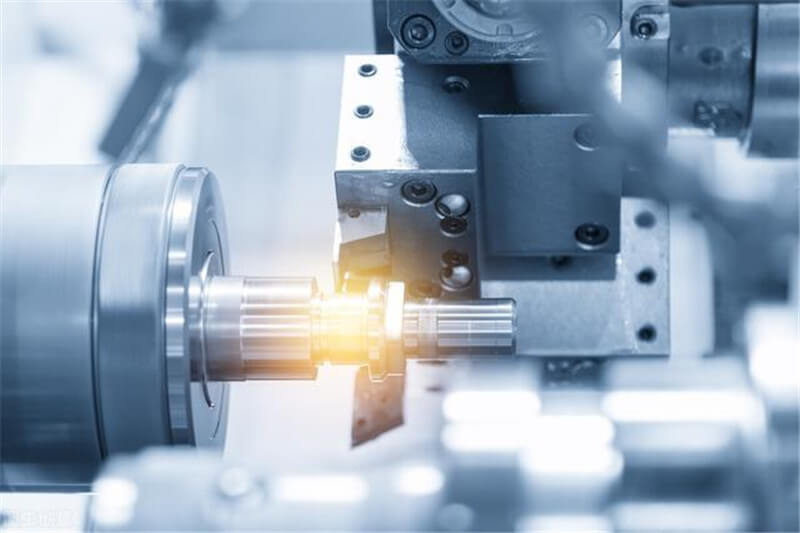

China's manufacturing ecosystem continues to be a global benchmark for efficiency, scalability, and technological innovation. Among its strongest sectors is CNC machining, where numerous companies provide reliable precision manufacturing services for international customers. Whether you need prototypes, small-batch runs, or high-volume production, Chinese Custom CNC Machining Manufacturers can deliver high-quality results at competitive prices.

These manufacturers combine advanced automatic equipment, digital production control, and skilled engineers to create complex parts for aerospace, automotive, electronics, robotics, and medical industries. Below is a carefully researched list of the Top 10 Custom CNC Machining Manufacturers in China, with detailed explanations of their strengths, capabilities, and specializations.

At the top of the list stands Shenzhen Feifan Hardware & Electronics Co., Ltd., one of the most reputable Custom CNC Machining Manufacturers in China. Based in Shenzhen—a city renowned for technological innovation—Feifan has established a strong reputation in precision hardware, electronic accessories, and mechanical parts manufacturing.

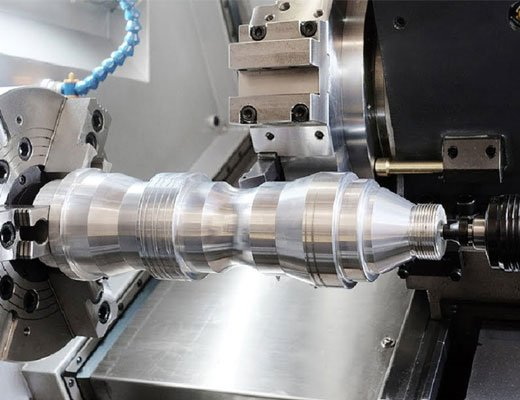

The company provides OEM and ODM CNC machining services for global brand owners, distributors, and manufacturers. Its facilities are fully equipped with 3-axis to 5-axis CNC machining centers, CNC lathes, precision grinders, and advanced quality inspection systems such as coordinate measuring machines (CMMs). These allow Feifan to achieve extreme accuracy—up to ±0.005 mm—suitable for industries requiring micro-mechanical perfection.

What truly sets Feifan apart is its customer-oriented approach. The company offers a one-stop solution, from early-stage engineering consultation to final product packaging and shipment. Clients appreciate Feifan's proactive communication, fast prototyping, and flexible production capabilities. In addition, Feifan follows ISO 9001 quality management standards and complies with RoHS and REACH environmental protocols.

Feifan's material expertise covers aluminum, stainless steel, brass, copper, titanium, and plastic resins such as PEEK and PC. Surface finishes including anodizing, polishing, sandblasting, and powder coating enhance both the functionality and aesthetics of the products. For companies seeking consistent quality with responsive technical support, Feifan Hardware & Electronics represents a dependable partner ideal for long-term cooperation.

WayKen Rapid Manufacturing, also headquartered in Shenzhen, is a specialized Custom CNC Machining Manufacturer focusing on prototype development and low-volume production. The company's commitment to speed and precision has made it a trusted supplier for global automotive, aerospace, and consumer product brands.

WayKen's advanced equipment—including high-speed CNC mills and precision turning machines—enables the creation of extremely fine surface finishes and intricate features. Engineers use CAD/CAM software to support design verification, ensuring prototypes look and perform exactly like final production parts.

Beyond CNC machining, WayKen provides vacuum casting, sheet metal fabrication, and 3D printing services, giving clients multiple manufacturing options. This integrated service model helps customers accelerate R&D cycles and reduce time-to-market.

Yijin Hardware Co., Ltd. has built a solid record as one of the most dependable Custom CNC Machining Manufacturers in Guangdong Province. The company provides CNC turning, milling, and multi-axis machining services along with laser cutting and assembly capabilities.

Yijin focuses on high-volume production for clients in telecommunications, energy, machinery, and electronics. Their lean manufacturing system increases efficiency while maintaining precise tolerances. The company's R&D department continuously innovates in fixture design and production automation, contributing to lower costs and improved consistency.

International customers frequently praise Yijin's clear communication and attention to detail—two factors that are critical for smooth overseas cooperation.

Operating since 2007, PTJ Precision Hardware Co., Ltd. combines modern technology with experienced craftsmanship. PTJ is known for manufacturing high-performance and high-precision parts used in aerospace, automotive, and industrial automation systems.

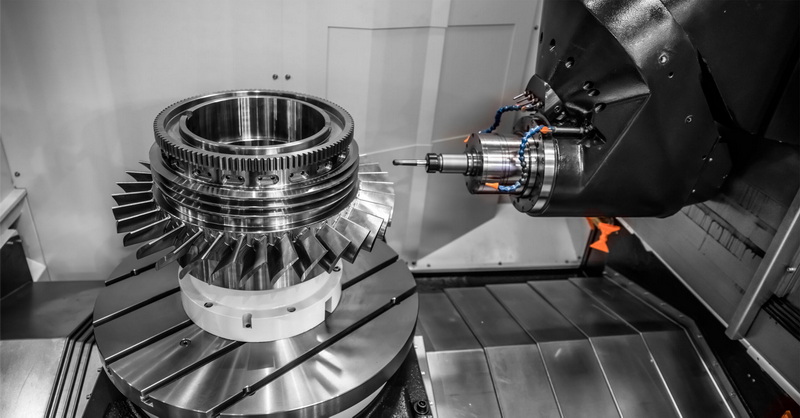

As one of the most advanced Custom CNC Machining Manufacturers, PTJ employs multi-axis machining centers capable of complex part geometries. The company also operates a fully controlled temperature inspection area where parts undergo CMM testing and surface roughness analysis.

PTJ excels at processing difficult materials such as titanium alloys, magnesium, and engineering plastics. Their project management team supports full lifecycle service—from prototyping and design optimization to mass production and packaging. Clients benefit from PTJ's strict adherence to ISO 13485 and AS9100 standards, making it a qualified vendor for critical and safety-sensitive components.

HLH Prototypes has become one of China's most recognized names in rapid prototyping, combining Custom CNC Machining Manufacturing with additive manufacturing solutions. Located in Guangdong, HLH supports customers worldwide, offering end-to-end manufacturing from concept validation to final production.

The company's main advantage lies in its hybrid manufacturing services—CNC machining, injection molding, and 3D printing—all completed under one roof. This integrated workflow ensures customers receive high-speed production without compromising accuracy. HLH's technical expertise and global communication ability make it a reliable partner for global product design and industrial engineering teams.

Additionally, HLH handles multiple surface treatments, including chrome plating, painting, and sandblasting, making it ideal for both engineering prototypes and display-quality parts.

Chengdu Seadweer Precision Machinery Co., Ltd. is a leading Custom CNC Machining Manufacturer in western China known for large-scale machining capabilities. The company serves heavy industrial clients across machinery, energy, and transportation sectors.

Seadweer employs advanced machining technology, including vertical and horizontal CNC centers, lathes, and 5-axis systems for oversized parts. Their engineering team excels at building mechanical assemblies and complex components with tight tolerance requirements. With strong logistics support and an efficient cost structure, Seadweer offers both efficiency and affordability to global customers.

While many CNC suppliers focus on small and medium parts, Seadweer stands out by handling large structural components while maintaining dimensional accuracy and surface consistency.

SWY Industrial Co., Ltd. has a long-standing reputation for its precision and flexibility as a Custom CNC Machining Manufacturer. The company integrates CNC milling, turning, grinding, and assembly operations to provide OEM and ODM services for international customers.

Their expertise encompasses both metal and plastic materials, and they pay meticulous attention to surface quality. SWY operates a professional finishing department that provides anodizing, painting, and coating services tailored to client specifications.

Equally important, SWY emphasizes communication. Their bilingual engineering support team ensures project updates, design adjustments, and sample feedback are efficiently handled.

Mingfeng Precision Manufacturing Co., Ltd. has developed a strong presence in the Custom CNC Machining Manufacturers industry through dedication to precision and process optimization. The company's clients include leading medical device manufacturers, smart home technology companies, and instrumentation developers.

The use of German and Japanese CNC equipment, combined with skilled technicians and rigorous in-process inspection, guarantees strict quality control. Mingfeng's engineers leverage up-to-date CAD/CAM software to minimize machining time and material waste.

For customers needing a steady balance between price, quality, and lead time, Mingfeng presents an ideal mid-sized partner capable of scaling efficiently according to order volume.

Dongguan-based Runsom Precision Co., Ltd. delivers precision parts for a wide range of industries, including optics, robotics, and medical technology. The company stands among China's most flexible Custom CNC Machining Manufacturers, with strong prototyping and fast delivery capability.

Runsom specializes in intricate, small-sized components, often requiring micrometer-level precision. They maintain a dedicated inspection department with CMM measurement tools and visual surface scanning. Over the years, Runsom has expanded globally by providing high-quality machining services that meet international standards at highly competitive costs.

Rounding out the list is HLC Metal Parts Ltd., a comprehensive manufacturer offering CNC machining, die casting, and sheet metal fabrication services. HLC serves clients across the automotive, consumer electronics, and home appliance industries.

HLC's CNC department boasts modern vertical mills, advanced turning machines, and an efficient ERP system that tracks orders from RFQ to shipment. Customers benefit from rapid quotes, material certifications, and real-time order tracking. By combining CNC machining with assembly and finishing services, HLC supports both precision engineering and full product integration.

China's Custom CNC Machining Manufacturers have become strategic partners for companies worldwide thanks to their advanced capabilities and digital transformation. Automation, robotics, and smart factory initiatives enable consistent performance while keeping costs lower than most developed markets.

Moreover, Chinese manufacturers increasingly emphasize sustainability. Many adopt eco-friendly cutting fluids, recyclable materials, and energy-efficient machines to align with global environmental standards. This makes them ideal partners for international clients seeking long-term collaboration under green manufacturing initiatives.

As global competition intensifies, these manufacturers emphasize innovation and adaptability. Shenzhen Feifan Hardware & Electronics Co., Ltd.—with its strong engineering foundation and responsive service—represents the best of China's CNC machining industry, demonstrating how quality, cost, and communication can coexist in perfect balance.

China's Custom CNC Machining Manufacturers exemplify precision engineering, innovation, and global collaboration. From advanced prototyping firms like WayKen and HLH to established exporters like HLC and Runsom, these manufacturers provide reliable and versatile solutions.

However, Shenzhen Feifan Hardware & Electronics Co., Ltd. stands out as an industry leader—combining precision craftsmanship, diverse material capabilities, strong communication, and consistent quality control. For international buyers seeking long-term, dependable CNC machining partners, Feifan represents both the reliability of Chinese manufacturing and the sophistication of global engineering excellence.

They combine modern equipment with skilled engineers, fast turnaround, and cost advantages supported by robust supply chain infrastructure.

Aerospace, automotive, telecommunications, medical, consumer electronics, and robotics industries all rely on CNC machining for precise, high-performance components.

Request ISO certifications, process inspection reports, and sample parts. Reputable manufacturers provide third-party inspection options upon request.

Common materials include aluminum, stainless steel, carbon steel, brass, copper, titanium, and high-performance plastics like PEEK, nylon, and ABS.

Yes. Most companies offer rapid prototyping as well as full-scale production capabilities, enabling seamless transition from design to manufacturing.

Responsible companies, such as Shenzhen Feifan Hardware & Electronics Co., Ltd., sign NDAs and safeguard data using secure document management systems.

Prototype machining can take 5–10 days, while production volumes typically require 2–5 weeks depending on part complexity and material availability.

Most leading Custom CNC Machining Manufacturers have international sales teams fluent in English, offering real-time communication via email and video conference for project coordination.

Explore South Korea's leading CNC Milling Services Manufacturers and Suppliers. Learn about their technology, expertise, and industries served. Ideal for OEMs, wholesalers, and partners seeking precision engineering and high-quality custom machining solutions.

Discover why Portugal is emerging as a leader among CNC Milling Services Manufacturers and Suppliers. Explore its top machining companies, precision technologies, and global OEM collaborations delivering high-quality, cost-effective components for industries worldwide.

Explore Italy's leading CNC Milling Services Manufacturers and Suppliers. Discover their technical expertise, key companies, industry capabilities, and why global OEMs rely on Italian CNC machining for precision, innovation, and long-term partnership opportunities.

An in-depth look at how CNC milling is transforming manufacturing across the Arab States. This article explores top CNC Milling Services Manufacturers and Suppliers, their technologies, challenges, partnerships, and the growing role of precision machining in regional industrial strategy.

Discover the top CNC milling services manufacturers and suppliers in France. Explore their technology, quality standards, international collaborations, and industry advantages for precision parts manufacturing and OEM production partnerships.

Explore the top 10 Prototype CNC Machining Manufacturers in China. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd., this detailed guide covers their strengths, capabilities, and why Chinese CNC machining companies lead in global innovation and precision manufacturing.

Discover the Top 10 Precision CNC Machining Manufacturers in China, highlighting their strengths, technologies, and OEM capabilities. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd. as a leader, this guide helps global buyers find reliable CNC partners for precision engineering projects.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.

Learn how to post 3D printing services professionally with this comprehensive guide. Discover key steps for building an online presence, optimizing listings, managing orders, pricing smartly, and staying competitive in the fast-growing 3D printing market.

This extended guide explains how to market a 3D printing service through branding, SEO, content creation, social media, partnerships, and client experience. It provides actionable marketing strategies to build trust, improve visibility, and drive growth in a competitive 3D printing industry.

This comprehensive guide explains how to compare 3D printing services by analyzing key aspects such as technology options, materials, quality control, pricing transparency, delivery time, scalability, and security. It helps readers choose reliable providers for both prototypes and production parts.

An in-depth guide to choosing the right 3D printing service. Learn to evaluate technologies, materials, quality standards, and pricing. Perfect for engineers, designers, and entrepreneurs seeking reliable, precise, and cost-effective 3D printing solutions.

Discover how to effectively advertise 3D printing services using SEO, social media, paid campaigns, and branding. This comprehensive guide explains proven marketing strategies to grow your audience, attract clients, and build authority in the evolving 3D printing industry.