From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-13 Origin: Site

Content Menu

● 1. Shenzhen Feifan Hardware & Electronics Co., Ltd.

● 2. Ningbo Ouyilai Precision Machining Co., Ltd.

● 3. Dongguan Promostar Hardware Co., Ltd.

● 4. Kunshan Tongxin Precision Machinery Co., Ltd.

● 5. Suzhou Jiding Precision Machinery Co., Ltd.

● 6. Shenzhen Tuofa Technology Co., Ltd.

● 7. Dongguan Hongye Precision Machinery Co., Ltd.

● 8. Jiaxing Xingcheng Precision Metal Co., Ltd.

● 9. Chengdu Seontek Precision Machining Co., Ltd.

● 10. Guangzhou Jincheng Precision Hardware Co., Ltd.

● Why Choose Chinese Precision CNC Machining Manufacturers?

● How to Choose the Right CNC Machining Partner

● Frequently Asked Questions (FAQs)

>> Q1: What industries depend most on precision CNC machining?

>> Q2: How do Chinese CNC machining manufacturers maintain quality consistency?

>> Q3: Can Chinese manufacturers produce prototypes as well as mass production?

>> Q4: What materials are most commonly used in CNC machining?

>> Q5: What are the typical lead times for international CNC machining projects?

>> Q6: How do CNC manufacturers ensure strong confidentiality for OEM clients?

>> Q7: Can I order small quantities from these companies?

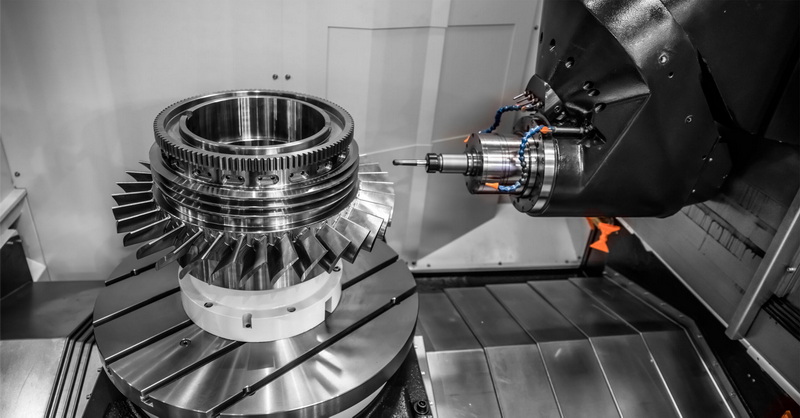

China has solidified its position as a world leader in precision machining and advanced engineering solutions. Over the past two decades, the nation has transformed from a low-cost manufacturing base into a global powerhouse of high-precision CNC machining manufacturers, producing reliable components used across aerospace, medical devices, automotive, robotics, and consumer electronics sectors.

The backbone of this growth lies in the strength of Chinese engineering, highly automated facilities, and abundant skilled technicians capable of executing complex designs with micron-level accuracy. International buyers now turn to China not only for competitive pricing but also for world-class quality and technical collaboration.

In this article, we explore the Top 10 Precision CNC Machining Manufacturers in China, highlighting their expertise, production capabilities, and unique strengths. Whether you're an OEM buyer, product developer, or mechanical engineer, this comprehensive overview will help you identify the most reliable suppliers for your next machining project.

Shenzhen Feifan Hardware & Electronics Co., Ltd. ranks first among the best precision CNC machining manufacturers in China for its impeccable engineering standards and OEM service excellence. Established in the innovation capital of Shenzhen, Feifan combines precision craftsmanship with smart manufacturing technologies to deliver outstanding results to global clients.

- 5-axis CNC machining: Feifan's workshops feature multi-axis machining centers from Japan and Germany capable of producing extremely complex and detailed geometries from a variety of materials.

- High-tolerance accuracy: Dimensional precision can reach up to ±0.002 mm, meeting demanding assembly and aerospace requirements.

- Full-suite OEM/ODM services: From design consultation, rapid prototyping, and DFM analysis to serial production, Feifan acts as a one-stop solution provider.

- Surface treatments and quality control: Anodizing, polishing, electroplating, and powder coating options ensure both aesthetic excellence and corrosion resistance.

The company adheres to the ISO 9001:2015 quality standard and uses a combination of CMM inspection, 3D scanning, and real-time process monitoring for each stage of production. Feifan's major international clients include firms in the medical, electronic, automation, and aerospace sectors.

Another major advantage is Feifan's customizable logistics and multilingual support team, ensuring seamless international cooperation. With over 15 years of experience, Shenzhen Feifan Hardware & Electronics has built a reputation for precision, punctuality, and partnership-driven service — making it a trusted name among global CNC machining manufacturers.

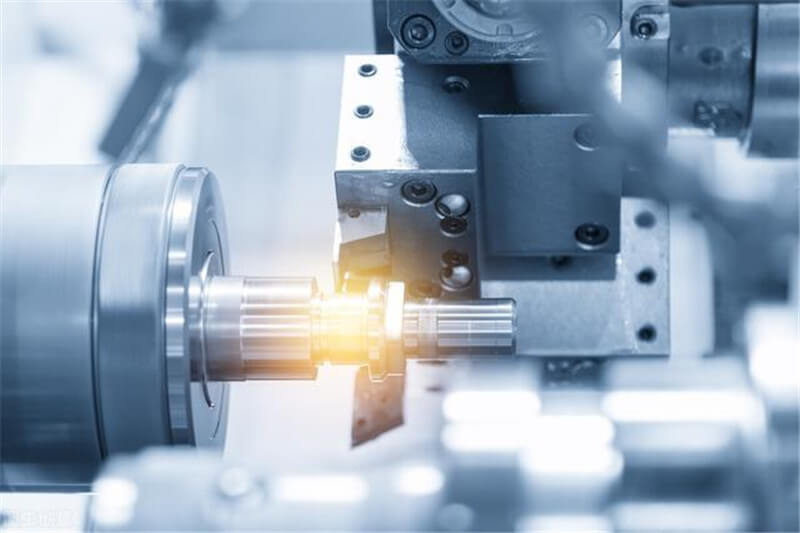

Located in Zhejiang Province, Ningbo Ouyilai Precision Machining Co., Ltd. is known for its sophisticated production setups and extensive experience in machining medium-to-large metal parts. The company specializes in CNC turning, milling, and EDM machining, backed by advanced simulation software that optimizes cutting paths and tool stability.

Ouyilai's expertise extends to multiple materials — aluminum alloys, stainless steel, copper, and engineering plastics — with finishes tailored to meet international OEM demands. They supply precision parts mainly to the automotive and renewable energy industries, working closely with clients throughout the product life cycle, from sample development to bulk manufacturing.

Dongguan Promostar Hardware is a leading provider of precision CNC machining services and an established exporter for over a decade. Located in Guangdong's manufacturing cluster, the company combines mechanical excellence with robust project management.

Promostar's equipment lineup includes high-speed milling machines, Swiss-type automatic lathes, and coordinate measuring instruments. Their production system integrates CAD/CAM software and ERP management, allowing full traceability and real-time progress tracking. This makes Promostar an ideal partner for companies requiring strict quality assurance and on-time delivery.

Kunshan Tongxin serves as a highly specialized manufacturer offering custom CNC machining services for automotive, military, and electronic component industries. Certified under ISO/TS 16949 standards, the company operates a modern facility equipped with automatic CNC turning and grinding centers.

Tongxin's engineers focus heavily on process optimization and lean manufacturing, resulting in rapid lead times without compromising quality. Their flagship products — precision shafts, bushings, gears, and brackets — are commonly exported to Germany, the United States, and Southeast Asia.

Suzhou Jiding Precision Machinery Co., Ltd. differentiates itself by combining precision machining with cleanroom assembly and micro-component production capabilities, enabling the company to serve high-tech and medical device industries.

Its factory integrates advanced 5-axis centers, 3D coordinate measuring systems, and automatic deburring machines. Jiding's manufacturing philosophy emphasizes “zero defect delivery” and continuous quality monitoring.

Their customer base includes clients from Switzerland, Japan, and North America who seek strict precision, small-pitch thread machining, and fine finishing — areas where Jiding's attention to detail gives them a distinct advantage.

Shenzhen Tuofa Technology is one of the fastest-growing OEM and CNC prototyping suppliers in southern China. With over ten years of technical experience, Tuofa specializes in rapid prototyping, low-volume machining, and sheet metal fabrication.

Their competitive edge comes from combining CNC machining, 3D printing, and die casting processes to shorten development cycles. Tuofa provides digital design verification and engineering consultation services, helping customers reduce production costs and avoid design errors.

Serving industries like robotics, electronics, and new energy, Tuofa is particularly lauded for its speed — often delivering prototypes within 48 hours while maintaining tight tolerances of ±0.005 mm.

Dongguan Hongye Precision Machinery Co., Ltd. is a comprehensive metal parts supplier with a well-built reputation among precision CNC machining manufacturers. The company invests heavily in automation and standardized management, ensuring consistency across multiple production lines.

Hongye's factory operates over 100 CNC machining centers, including 4-axis and 5-axis models. They combine data-driven production monitoring systems with experienced machinists to achieve both speed and accuracy.

Their main export markets include North America and Western Europe, where they supply precision fittings, fasteners, and tooling components used in automated machinery and industrial systems.

Located in Zhejiang, Jiaxing Xingcheng Precision Metal Co., Ltd. provides CNC turning and milling services tailored to the needs of industrial suppliers, electronics producers, and mechanical engineers.

Xingcheng integrates high-speed machining systems with real-time inspection to deliver consistent quality for parts requiring high concentricity and flatness. Their on-site anodizing and nickel plating workshops enable end-to-end quality control and cost-efficient production.

They also employ a digital ERP management system that tracks every batch by serial number, giving clients full transparency at each manufacturing stage — a hallmark of top-tier precision CNC machining manufacturers.

Based in the technological hub of western China, Chengdu Seontek merges advanced CNC machining and robotic automation to produce ultra-precise parts for demanding sectors like aerospace and automotive. The company's R&D team continuously develops new jigs, vertical machining tools, and fixture systems to improve geometry accuracy.

Seontek's manufacturing combines tight-tolerance milling, CNC lathe operations, and EDM processes to machine titanium, Inconel, and other difficult-to-cut materials. They also prioritize environmental sustainability, using coolant recycling systems and optimized tool paths that reduce waste.

By aligning innovation and responsibility, Seontek represents the modern face of China's precision manufacturing evolution.

Rounding out the list, Guangzhou Jincheng Precision Hardware Co., Ltd. is known for its meticulous attention to fine metal components and subassemblies. Serving industries such as automotive manufacturing, industrial automation, and home appliances, Jincheng is a preferred supplier for both domestic and international customers seeking consistent product quality.

Their infrastructure includes CNC lathes, surface grinders, automatic thread rolling machines, and optical inspection systems. Jincheng combines practical manufacturing experience with an emphasis on customer collaboration — offering flexible order quantities and comprehensive technical guidance throughout every project.

Partnering with a Chinese precision CNC machining manufacturer provides several strategic advantages for global businesses:

1. Advanced technology: Leading Chinese factories now use imported high-precision machines from Mazak, Haas, and DMG Mori, ensuring international production standards.

2. Cost competitiveness: Localized sourcing networks and optimized labor costs create outstanding value without sacrificing performance.

3. Versatile customization: Chinese manufacturers can design, prototype, and mass-produce parts for different sectors and specifications seamlessly.

4. Strong quality systems: Many companies implement ISO 9001 or IATF 16949 certification and maintain robust traceability documentation.

5. Global logistics and communication: Bilingual engineering teams and partnerships with DHL, FedEx, and local freight providers ensure smooth exports.

For businesses pursuing performance-driven solutions, China's CNC machining ecosystem offers an unmatched combination of technology, scalability, and service quality.

When searching for the best precision CNC machining manufacturer in China, keep these essential factors in mind:

- Technical capability: Review the manufacturer's equipment list, focusing on 4-axis or 5-axis CNC capabilities and tolerance ranges.

- Industry specialization: Match your industry requirements — aerospace, medical, or automotive — with the supplier's existing client base.

- Design support and DFM analysis: A reliable partner should assist in optimizing your drawings for production efficiency.

- After-sales service: Consider long-term reliability, maintenance support, and post-production quality tracking.

- Transparency: Choose manufacturers that provide inspection reports, certificates of material origin, and supply-chain documentation.

As global demands for accuracy, efficiency, and customization grow, China's precision CNC machining manufacturers continue to set new industry benchmarks. Their success stems from the perfect balance of craftsmanship, advanced machining technologies, and responsive customer service.

Among them, Shenzhen Feifan Hardware & Electronics Co., Ltd. exemplifies excellence — delivering precision-machined components that consistently earn international trust. From multi-axis machining to comprehensive OEM services, Feifan and its peers demonstrate the extraordinary potential of modern Chinese manufacturing.

Whether you are developing an aviation-grade prototype or a high-volume industrial part, partnering with one of these top 10 manufacturers ensures unmatched precision, reliability, and cost efficiency. In today's globalized market, precision isn't just a technical requirement — it's a strategic advantage, and China continues to lead that transformation.

A1: Precision CNC machining is essential to industries like aerospace, automotive, robotics, electronics, medical devices, and renewable energy, where tight tolerances and mechanical reliability are non-negotiable.

A2: They employ multi-level inspection — including dimensional test reports, hardness and roughness checks, and CMM analysis — to ensure uniformity across all production runs.

A3: Yes. Many leading companies such as Shenzhen Feifan and Tuofa Technology offer both rapid prototyping and scalable full production, maintaining continuous quality throughout.

A4: Standard materials include aluminum alloys (6061, 7075), stainless steel (304, 316), brass, titanium, copper, and various plastics like PEEK and ABS.

A5: Prototyping can take 3–7 days, while standard mass production typically ranges from 2–5 weeks, depending on complexity and finishing.

A6: Top-tier manufacturers sign non-disclosure agreements (NDAs) and maintain encrypted digital storage for design files and CAD data.

A7: Yes, several manufacturers specialize in low-volume, high-precision parts, providing flexibility for R&D teams and startups.

Is CNC machining expensive? This detailed guide breaks down every factor influencing CNC cost—from materials and machine time to tolerances and production volume—while offering expert strategies to reduce expenses and maximize manufacturing efficiency.

This in-depth article explores whether CNC machining is dangerous, detailing potential hazards, critical safety measures, advanced automation, and operator best practices. It also covers regulatory standards, sustainability, and includes a comprehensive FAQ on CNC safety management.

This comprehensive article examines whether CNC machining qualifies as blue-collar work. It traces the role's history, skills, and education, highlighting its evolution into a gray-collar profession that fuses craftsmanship, technology, and digital competence in modern manufacturing.

This article explores whether CNC machining is a dying trade. It concludes that far from disappearing, CNC machining is evolving with automation, AI, and Industry 4.0 integration. The trade remains vital to global manufacturing, offering lasting opportunities for innovation and skilled careers.

This complete guide explains how to start and grow a CNC machining business — from planning, financing, and equipment selection to marketing, automation, and sustainability. Learn expert strategies to build a profitable precision manufacturing company in today's competitive market.

Explore South Korea's leading CNC Milling Services Manufacturers and Suppliers. Learn about their technology, expertise, and industries served. Ideal for OEMs, wholesalers, and partners seeking precision engineering and high-quality custom machining solutions.

Discover why Portugal is emerging as a leader among CNC Milling Services Manufacturers and Suppliers. Explore its top machining companies, precision technologies, and global OEM collaborations delivering high-quality, cost-effective components for industries worldwide.

Explore Italy's leading CNC Milling Services Manufacturers and Suppliers. Discover their technical expertise, key companies, industry capabilities, and why global OEMs rely on Italian CNC machining for precision, innovation, and long-term partnership opportunities.

An in-depth look at how CNC milling is transforming manufacturing across the Arab States. This article explores top CNC Milling Services Manufacturers and Suppliers, their technologies, challenges, partnerships, and the growing role of precision machining in regional industrial strategy.

Discover the top CNC milling services manufacturers and suppliers in France. Explore their technology, quality standards, international collaborations, and industry advantages for precision parts manufacturing and OEM production partnerships.

Explore the top 10 Prototype CNC Machining Manufacturers in China. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd., this detailed guide covers their strengths, capabilities, and why Chinese CNC machining companies lead in global innovation and precision manufacturing.

Discover the Top 10 Precision CNC Machining Manufacturers in China, highlighting their strengths, technologies, and OEM capabilities. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd. as a leader, this guide helps global buyers find reliable CNC partners for precision engineering projects.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.