From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-12 Origin: Site

Content Menu

● Understanding Eccentric Turning

● Equipment and Setup Requirements

>> 1. Coordinate Offset Method

>> 2. Physical Repositioning Method

>> 3. G-Code Programming Example

● Tool Selection and Cutting Parameters

● Balancing, Vibration, and Stability Control

● Measuring and Quality Control

● Common Defects and Troubleshooting

● Advanced Machining Techniques

● FAQ

>> 1. What makes eccentric turning different from concentric turning?

>> 2. What's the best way to reduce vibration during eccentric turning?

>> 3. Can eccentric turning be done on any CNC lathe?

>> 4. How do you measure the eccentricity after machining?

>> 5. What materials are easier to machine eccentrically?

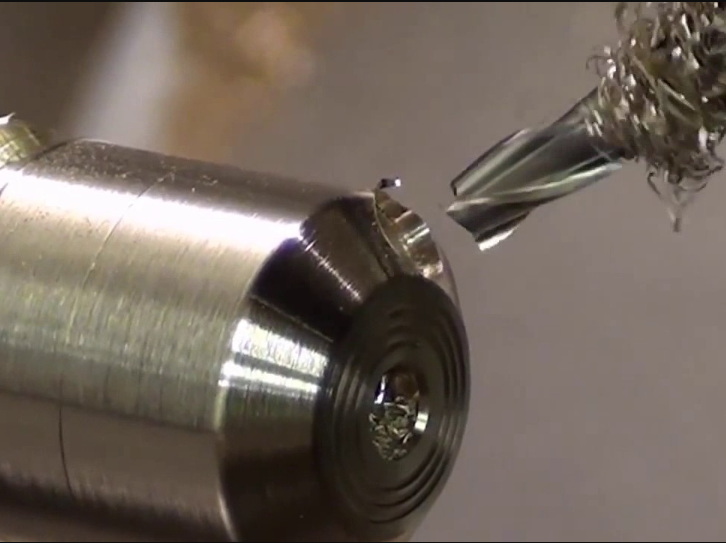

Eccentric turning is a specialized machining process in which different sections of a cylindrical component are turned at varying axes of rotation. This process is essential in creating components such as crankshafts, cams, eccentric bushes, motor shafts, and mechanical couplings. In simple terms, while concentric turning involves machining along a single axis, eccentric turning intentionally shifts the center axis to create offset diameters.

In modern machining environments, CNC (Computer Numerical Control) lathes have revolutionized how eccentric turning is performed. They provide the ability to control the offset dynamically, define multiple coordinate systems, and perform repetitive eccentric operations with remarkable precision. However, to achieve reliable results, one must understand proper setup techniques, tool selection, and programming strategies. This article explores these elements in detail, guiding you step by step through the process of eccentric turning on CNC machines.

The defining feature of eccentric turning is that the machined surface does not share the same center as the main axis of rotation. Instead, the workpiece rotates about a secondary axis, offset from the center by a precise distance, known as the eccentricity. Each eccentric section of the workpiece can have its own axis, parallel to the main spindle axis but displaced.

Eccentric turning enables the creation of functional parts that translate rotary motion to linear motion, absorb vibrations, or create intentional mechanical imbalances for specific machine movements. For instance, crankpins in automotive crankshafts are machined eccentrically to convert piston motion into rotation. Similarly, cams use offset geometry to control valve timing in internal combustion engines.

Because the tool engages varying surface distances from the rotation center, the cutting force changes with every revolution. This makes the machinist's control of vibration, balance, and clamping critical to achieving accuracy and preventing early tool wear.

Before beginning eccentric turning, ensure the machine and accessories meet the process demands. The following elements are essential:

1. Precision CNC Lathe: The lathe should allow accurate spindle motion, axis offset programming, and coordinate shifts. Multi-axis lathes or machines with live tooling provide more flexibility.

2. Workholding Device: Use specialized adjustable chucks, eccentric soft jaws, or custom fixtures that can hold the part securely at the desired offset.

3. Counterweights: These balance the uneven load to minimize vibration and prevent damage to the spindle bearings.

4. CAD/CAM System: Design software helps in modeling offset features and generating corresponding tool paths. Simulation allows operators to detect potential interferences or collisions.

5. Skilled Operator: Experience is required to correctly interpret alignment gauges, zero coordinates, and compensate for tool deflection.

A properly configured environment minimizes trial errors, reduces production time, and improves dimensional accuracy.

Setting up for eccentric turning requires precision in alignment and workpiece positioning. The process typically follows these steps:

1. Main Axis Turning: Begin by machining the initial diameter concentrically to ensure it is true and smooth.

2. Determine Offset Distance: Identify the eccentricity value from the technical drawing or CAD model. This is the displacement between the main and secondary axes.

3. Mounting and Clamping: Use a four-jaw independent chuck or an eccentric collet chuck to clamp the workpiece. Adjust the jaws until the desired offset is achieved.

4. Offset Verification: Use a dial test indicator to verify the displacement. Rotate the chuck by hand to ensure the eccentric offset is consistent through the entire length.

5. Secondary Setup: For parts requiring multiple offsets, mark each center and reposition the workpiece accordingly between operations.

6. Dynamic Balancing: If the part is long or heavy, balance the setup using counterweights or reduce spindle speeds to maintain stability.

A well-balanced setup ensures safer operations and consistent surface finish throughout machining.

Eccentric turning can be accomplished through coordinate system shifts or by physically repositioning the workpiece. CNC controllers simplify this process by allowing multiple work coordinate systems (WCS), such as G54–G59, each with its unique zero point offset.

In this method, the part remains fixed while the coordinate origin in the control software is shifted to create new axes. For every eccentric section, define a separate work offset. The amount of shift in the X or Y direction represents the eccentric distance.

For example, if the main axis uses G54 and the offset section is displaced by 3 mm in the X direction, the programmer defines G55 with an X-shift of 3 mm.

In simpler or older CNC lathes without multiple offset capabilities, the operator repositions the part manually using an independent chuck. After machining the concentric portion, the part is reclamped off-center to create the desired offset features.

T0101

G54

G50 S2000

G96 S250 M03

G00 X50.0 Z2.0

G01 Z-40.0 F0.15

(Offset section)

G55

G00 X45.0 Z2.0

G01 Z-20.0 F0.12

M30

Here, G55 defines a new work coordinate, enabling the machine to perform offset turning operations sequentially without readjusting the chuck.

Eccentric turning exposes the tool to intermittent cuts and variable loads due to the offset rotation. Choosing the right cutting tools and parameters is critical.

- Insert Type: Use carbide or cermet inserts with high toughness to withstand interrupted cutting.

- Rake Angle: A positive rake angle reduces cutting forces and vibration.

- Nose Radius: A small nose radius (0.4–0.8 mm) helps maintain precision on small diameters.

- Feed and Speed: Lower spindle speeds reduce imbalance effects. Typical cutting speed should be 60–80% of the speed used for concentric turning.

- Coolant: Apply continuous coolant to minimize heat, prevent tool chipping, and improve surface finish.

Tool rigidity and sharpness must be maintained throughout the process. Frequent tool inspections reduce the chance of dimensional inaccuracy caused by wear.

Since eccentric turning naturally causes uneven mass distribution, controlling vibration is crucial for accurate machining. Imbalance increases radial loads on the spindle and bearings, potentially shortening their lifespan.

Recommended practices include:

- Reducing rotational speed during initial passes.

- Using dynamic balancing units for heavy or long workpieces.

- Ensuring firm tool clamping and minimum tool overhang.

- Installing rubber or polymer dampers to absorb machine vibration.

- Employing constant surface speed (CSS) only within safe RPM limits.

When high eccentricity values are involved, it's advisable to test rotation manually before engaging automatic feed to confirm balance stability.

After machining, verifying the part's geometrical accuracy ensures that the offsets were correctly created. Several techniques can be used:

1. Dial Indicators: Measure total indicated runout (TIR) to determine eccentricity.

2. Micrometers and Calipers: Verify dimensional accuracy of each diameter and offset length.

3. CMM Machines: Coordinate measuring machines offer the highest accuracy by mapping all machined surfaces.

4. Surface Roughness Tester: Evaluates the quality of the finish to ensure it meets design specifications.

5. Runout Gauge: Continuously monitors the eccentric deviation across multiple axis shifts.

Precise measurement not only ensures compliance but also helps optimize future setups through recorded data feedback.

Eccentric turning introduces unique hazards because of unbalanced motion. Always follow strict safety practices:

- Confirm all chucks and fixtures are securely tightened before rotation.

- Do not exceed recommended spindle speeds.

- Keep guards and enclosure doors closed.

- Avoid standing in the plane of rotation.

- Monitor tool vibration and stop immediately if abnormal noise occurs.

- Use personal protective equipment such as goggles and gloves.

By adhering to these safety precautions, both operator and machine remain protected throughout the operation.

| Issue | Possible Cause | Corrective Action |

|---|---|---|

| Excessive vibration | Imbalance, poor clamping | Add counterweights, realign workpiece |

| Dimensional error | Incorrect offset setup | Recheck WCS or offset distance |

| Tool wear | High cutting temperature | Reduce feed rate, improve cooling |

| Chatter marks | Loose tool or insufficient rigidity | Tighten toolpost, shorten overhang |

| Irregular surface finish | Dull insert or unstable chuck | Replace tool, inspect fixture |

Preventive maintenance and consistent parameter control significantly reduce these issues.

Modern CNC technology allows several innovations that improve eccentric turning efficiency:

1. Live Tooling: Enables simultaneous turning and milling of eccentric profiles without reclamping.

2. Sub-Spindle Synchronization: Allows machining of both ends of an eccentric workpiece in one setup.

3. Adaptive Feed Control: Monitors cutting load and adjusts feed automatically to maintain consistent forces.

4. Simulation Software: Predicts tool interference and verifies offset geometry before machining starts.

These methods enhance accuracy, reduce manual errors, and shorten production cycles, making eccentric turning feasible even for complex multi-offset components.

Eccentric turning on a CNC machine combines the precision of digital programming with the mechanical skill of proper setup and balancing. The essence of this method lies in controlling offset geometry—creating perfect alignment between multiple axes while maintaining stability and accuracy. The process demands patience in setup, careful monitoring of vibration, and consistent attention to fixture alignment.

With successful application, manufacturers can create sophisticated components such as crankshafts, cams, and eccentric gears efficiently and with remarkable precision. As CNC control systems continue to evolve, eccentric turning will become even more capable, empowering machinists to produce parts that were once challenging through conventional methods.

Concentric turning uses a single centerline for all operations, while eccentric turning involves machining around one or more offset axes parallel to the main spindle axis.

Lower spindle speed, use counterweights, secure the workpiece tightly, and employ damping pads or vibration monitoring systems.

Not all. The machine should support coordinate system shifting or physical offset adjustment. High-precision or multi-axis lathes are ideal.

Use a dial indicator or CMM to measure the radial difference between the concentric and eccentric surfaces while rotating the part about its main axis.

Mild steel, aluminum alloys, and brass are preferred because they offer good machinability and stability under alternating cutting loads.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.

Learn how to post 3D printing services professionally with this comprehensive guide. Discover key steps for building an online presence, optimizing listings, managing orders, pricing smartly, and staying competitive in the fast-growing 3D printing market.

This extended guide explains how to market a 3D printing service through branding, SEO, content creation, social media, partnerships, and client experience. It provides actionable marketing strategies to build trust, improve visibility, and drive growth in a competitive 3D printing industry.

This comprehensive guide explains how to compare 3D printing services by analyzing key aspects such as technology options, materials, quality control, pricing transparency, delivery time, scalability, and security. It helps readers choose reliable providers for both prototypes and production parts.

An in-depth guide to choosing the right 3D printing service. Learn to evaluate technologies, materials, quality standards, and pricing. Perfect for engineers, designers, and entrepreneurs seeking reliable, precise, and cost-effective 3D printing solutions.

Discover how to effectively advertise 3D printing services using SEO, social media, paid campaigns, and branding. This comprehensive guide explains proven marketing strategies to grow your audience, attract clients, and build authority in the evolving 3D printing industry.

This in-depth article explains what defines the best CNC milling machine, highlighting critical technical features, top brands, maintenance tips, and emerging smart manufacturing trends. It concludes with expert advice and FAQs, guiding readers toward the ideal CNC solution for their needs.

This detailed article explores CNC turning and milling processes, explaining their working principles, differences, advantages, and modern applications. It examines recent technological innovations, environmental aspects, and integration trends shaping precision manufacturing in the Industry 4.0 era.

CNC milling is a computer-controlled machining process that creates precise, complex parts from metal or plastic. Used across industries like aerospace, medical, and automotive, it offers high precision, consistency, and adaptability for both prototypes and large-scale manufacturing.

Explore the technology behind 5-axis CNC milling machines, including their operation, types, advantages, and industrial uses. Discover how multi-axis control enhances precision, reduces setup time, and drives innovation in aerospace, automotive, and manufacturing industries.

CNC milling combines computer precision and mechanical control to produce complex, high-accuracy components. Learn how CNC milling works, machine types, materials, advantages, and applications across industries. Includes detailed FAQs exploring its accuracy and future potential.

This detailed guide explains how to get CNC machining work through marketing, client networking, quoting strategies, technology upgrades, and brand development. It helps workshops attract steady contracts, enhance reputation, and stay competitive in the global machining industry.

Learn how to estimate CNC machining time accurately with formulas, real-world examples, and optimization techniques. Understand key factors such as materials, tooling, and machine parameters that influence cycle time and cost efficiency in modern CNC manufacturing.