From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-13 Origin: Site

Content Menu

● 1. Shenzhen Feifan Hardware & Electronics Co., Ltd.

● 3. WayKen Rapid Manufacturing

● 4. Kintek Precision Machining Co., Ltd.

● 9. Junying Metal Manufacturing Co., Ltd.

● 10. First Part Manufacturing Ltd.

● Why Chinese Prototype CNC Machining Manufacturers Dominate the Global Market

● How to Choose the Right CNC Machining Partner

● FAQs about Prototype CNC Machining Manufacturers in China

>> Q1: Which materials do Chinese CNC manufacturers typically work with?

>> Q2: How quickly can I receive a prototype from China?

>> Q3: Are Chinese Prototype CNC Machining Manufacturers reliable in quality?

>> Q4: Can these manufacturers support both prototyping and full production runs?

>> Q5: How can international clients ensure secure transactions?

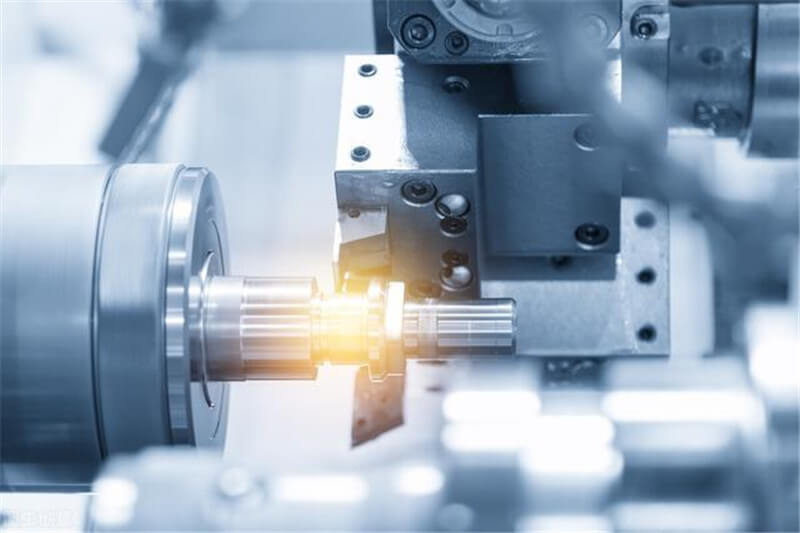

China has become a global leader in advanced manufacturing over the past two decades, particularly in the field of Prototype CNC Machining Manufacturers. These companies have revolutionized how global businesses bring their product designs to life, offering precision engineering, rapid prototyping, and efficient mass production capabilities. From the bustling hubs of Shenzhen and Dongguan to the industrial centers of Suzhou and Ningbo, Chinese manufacturers combine cutting-edge technology with skilled craftsmanship to deliver components that meet the highest international standards.

For overseas brands, wholesalers, and product designers, partnering with a reliable Chinese CNC machining firm offers multiple advantages — competitive pricing, speed, flexibility, and a commitment to customization. The following list introduces the Top 10 Prototype CNC Machining Manufacturers in China, emphasizing their unique strengths, technical expertise, and contributions to global manufacturing excellence.

At the top of our list is Shenzhen Feifan Hardware & Electronics Co., Ltd., one of China's most respected and forward-thinking Prototype CNC Machining Manufacturers. Located in the high-tech city of Shenzhen, Feifan specializes in precision OEM manufacturing, custom metal and plastic components, and one-stop prototype solutions for international brands and industrial clients.

Feifan's product range covers CNC milling, CNC turning, die casting, sheet metal fabrication, and surface finishing. Their strength lies not only in machinery but also in strong engineering know-how and tight process control. The company has invested in advanced 3-axis to 5-axis CNC centers, ensuring high efficiency for both small-batch prototyping and mass production.

What sets Feifan apart is its design-to-delivery support system. Their engineers provide DFM (Design for Manufacturability) feedback, 3D model analysis, and cost optimization before production even starts. This approach helps clients avoid costly mistakes and design inefficiencies.

Feifan serves industries such as aerospace, medical devices, automotive, robotics, and consumer electronics, manufacturing precision components with tolerances as tight as ±0.005 mm. International certifications including ISO 9001:2015 ensure the highest quality standards. Additionally, the company has bilingual project managers for seamless global communication and on-time delivery.

In short, Shenzhen Feifan Hardware & Electronics Co., Ltd. embodies what today's global market demands — speed, precision, transparency, and partnership. It is the first choice for clients who require dependable and professional Prototype CNC Machining Manufacturers in China.

RapidDirect has become a household name in China's CNC machining scene thanks to its advanced digital manufacturing ecosystem. Headquartered in Shenzhen, RapidDirect specializes in rapid prototyping, CNC machining, and on-demand manufacturing.

One of their biggest advantages is an AI-powered online quoting platform, which allows clients to upload 3D CAD files and receive automated pricing within minutes. This system streamlines the entire production process, from quotation to order fulfillment, minimizing human delays and maximizing transparency.

The company's powerful machining center uses multi-axis equipment capable of efficiently machining metals and plastics. Their clients range from small startups to Fortune 500 corporations across the automotive, drone, and electronics sectors. RapidDirect's commitment to data management, quality tracking, and environmental sustainability further establishes its position among China's best Prototype CNC Machining Manufacturers.

WayKen Rapid Manufacturing focuses on custom prototypes and precision parts for functional testing and product validation. With a client base that includes both industrial companies and design studios, WayKen provides CNC machining, vacuum casting, SLA/SLS 3D printing, and low-volume production.

WayKen stands out for its meticulous attention to detail and smooth surface finishing, which make its prototypes ideal for both functional testing and marketing display. Its engineers often collaborate directly with clients during the design phase to ensure manufacturability and optimal material performance.

The company also takes pride in its project management system, which tracks every step — from raw material sourcing to final inspection — ensuring consistency, precision, and transparency. This combination of high-quality service and strong technical understanding has earned WayKen a solid reputation as one of China's most reliable Prototype CNC Machining Manufacturers.

Located in Dongguan, Kintek Precision Machining Co., Ltd. specializes in ultra-precise metal machining for sectors requiring strict tolerances and stable performance. Their primary services include 5-axis CNC milling, precision turning, and micron-level surface grinding.

Kintek operates under rigorous standards, with a quality management system certified to ISO 9001:2015, ensuring that each batch meets strict industry expectations. Their investment in CMM (Coordinate Measuring Machine) technology and automated measuring systems allows the company to guarantee exceptional dimensional accuracy.

Their customers include aerospace contractors, semiconductor equipment manufacturers, and scientific researchers, all of whom rely on Kintek for accurate, repeatable results. For clients prioritizing precision, Kintek remains one of the most trustworthy choices among Prototype CNC Machining Manufacturers in China.

With dual facilities in Shenzhen and Dongguan, HLH Prototypes offers one of the most diverse service portfolios among Chinese CNC manufacturers. Their capabilities include CNC milling and turning, 3D printing, sheet metal fabrication, vacuum casting, and injection molding.

HLH emphasizes a seamless transition from prototype validation to low-volume production. This flexibility helps clients bring new products to market faster and with better control over quality and lead times. Their engineers focus on optimizing the machining process — reducing unnecessary tool changes, improving surface roughness, and ensuring consistency across materials.

The company's clients often highlight HLH's global experience, noting its professionalism, customer support, and ability to meet Western quality standards. It continues to be a major name among global Prototype CNC Machining Manufacturers for integrated, multi-process production services.

Star Rapid is a pioneer in combining Western management with Chinese manufacturing efficiency. Established by British engineer Gordon Styles, the company provides prototype CNC machining, rapid tooling, and low-volume manufacturing services to clients around the world.

Star Rapid's plant is equipped with modern 5-axis CNC centers that can achieve micrometer-level tolerances. They work with metals like aluminum and stainless steel and plastics like PEEK and nylon. Their combination of technical excellence and customer transparency attracts clients in medical technology, robotics, and renewable energy industries.

Their strong emphasis on quality inspection — using techniques such as non-contact measurement and material testing — ensures every product meets exact specifications. This makes Star Rapid one of the most reliable Prototype CNC Machining Manufacturers for customers who expect international-grade service quality backed by local cost advantages.

DEK Manufacturing, based in Suzhou, offers full-service precision machining and prototyping for complex components. The company is particularly distinguished by its 100% quality inspection policy and its ability to meet extremely tight tolerances.

DEK provides CNC milling, turning, EDM, and surface finishing services, with experience across multiple industries such as automation, robotics, instrumentation, optics, and fluid technology. Their engineers constantly refine production methodologies to enhance efficiency while maintaining superior quality.

Moreover, DEK is deeply invested in sustainability, adopting energy-efficient machining systems and waste recycling practices. This eco-conscious approach makes DEK a unique presence among Chinese Prototype CNC Machining Manufacturers aiming for greener production standards.

With more than 20 years of experience, RPWORLD focuses on small-batch production and prototype manufacturing. The company serves international clients that require not only high-quality machining but also flexible engineering input.

RPWORLD operates advanced German and Japanese-made CNC equipment combined with automated inspection systems. Its expertise extends to plastics, composite materials, and specialized alloys. The company's process is fully digitalized: customers can track the production status of their prototypes in real time through an online portal.

On top of its technical strength, RPWORLD invests in sustainable operations, reducing energy consumption and minimizing material waste. It continues to grow as one of the world's most reputable Prototype CNC Machining Manufacturers identified with precision, sustainability, and innovation.

Junying Metal Manufacturing Co., Ltd. (JY Machine) provides a wide range of CNC machining services, from 3-axis to 5-axis CNC milling, precision turning, and EDM wire cutting. Known for its flexibility, Junying serves clients ranging from startups to large industrial conglomerates.

The company's experienced engineers are skilled in processing difficult-to-machine materials such as titanium and copper alloys, making Junying an ideal partner for industries like automotive, defense, and industrial automation. They offer both prototyping and mass-production capabilities, emphasizing cost efficiency and consistent quality.

What customers appreciate most is Junying's transparent workflow, immediate quotes, and personalized engineering suggestions — qualities that help position it among the top Prototype CNC Machining Manufacturers catering to global clients.

Rounding out our list is First Part Manufacturing Ltd., a seasoned manufacturer renowned for precision, consistency, and customer-centered collaboration. The company offers comprehensive prototyping services, including CNC machining, injection molding, and 3D printing.

First Part's manufacturing process is supported by advanced CAM software like Mastercam and SolidWorks, ensuring optimal tool paths and machining efficiency. The company's English-speaking support team keeps foreign clients updated at every stage through an online project management system.

The company's core philosophy emphasizes design-driven manufacturability — converting customer ideas into functional, high-quality prototypes ready for full-scale production. With its focus on speed, accuracy, and communication, First Part continues to be one of China's most reliable Prototype CNC Machining Manufacturers for international projects.

China's competitive strength doesn't come solely from cost advantage. Modern Prototype CNC Machining Manufacturers in China have evolved to integrate automation, advanced metrology, and data-driven process optimization — all essential for meeting global market expectations.

Key advantages include:

- State-of-the-art machinery: From 5-axis machining centers to robotic tool changers, Chinese factories rival Western technology standards.

- Scalability: Many suppliers, such as Feifan, can seamlessly shift from single prototypes to large-scale production.

- Material variety: Access to high-quality raw materials, including aerospace-grade metals and engineering plastics.

- Quality control: Widespread adoption of ISO and IATF standards ensures repeatable accuracy.

- Speed & efficiency: Advanced logistics networks allow prototypes to be shipped globally within days.

These combined strengths make China's Prototype CNC Machining Manufacturers essential partners for accelerating the global innovation cycle.

Selecting the right manufacturing partner among numerous Chinese suppliers can seem daunting. Consider the following key criteria:

1. Technical expertise: Evaluate whether the manufacturer has experience with your specific materials and part complexity.

2. Certifications and quality assurance: Always verify compliance with ISO, RoHS, and other relevant standards.

3. Communication skills: Effective English communication avoids misunderstandings and ensures smooth cooperation.

4. Proven track record: Review project references, case studies, or customer testimonials.

5. Flexibility and scalability: Opt for suppliers offering both prototype and mass production options.

6. After-sales service: Ensure the company provides follow-up support, modifications, or finishing assistance when needed.

By carefully vetting suppliers, international buyers can secure partnerships that ensure long-term production reliability and innovation alignment.

China's Prototype CNC Machining Manufacturers continue to redefine precision, quality, and efficiency in modern manufacturing. Companies like Shenzhen Feifan Hardware & Electronics Co., Ltd. lead the industry by blending advanced machinery with customer-oriented engineering support. From concept design to mass production, these firms enable innovation across industries — electronics, aerospace, automotive, and more.

For international businesses seeking dependable OEM partners, China offers unparalleled technical expertise, rapid turnaround, and cost-effectiveness. Partnering with the right manufacturer ensures that your ideas transform into tangible, high-quality products with global competitiveness.

With continuous innovation and excellence as their foundation, the future of Prototype CNC Machining Manufacturers in China looks brighter than ever.

A1: They frequently process aluminum, stainless steel, brass, titanium, and plastics such as POM, ABS, PC, and nylon. Some also handle composites and specialized alloys.

A2: Depending on design complexity, lead times typically range between 3 to 10 business days, including surface finishing and international delivery.

A3: Yes. Reputable companies like Feifan, RapidDirect, and HLH operate under internationally recognized standards such as ISO 9001 and implement 100% inspection before shipment.

A4: Absolutely. Many top-tier companies are equipped to scale from low-volume prototyping to large-batch manufacturing using the same machinery and standards.

A5: Most manufacturers accept payments through secure channels such as Alibaba Trade Assurance, PayPal, or T/T bank transfers, ensuring buyer protection and traceability.

Is CNC machining expensive? This detailed guide breaks down every factor influencing CNC cost—from materials and machine time to tolerances and production volume—while offering expert strategies to reduce expenses and maximize manufacturing efficiency.

This in-depth article explores whether CNC machining is dangerous, detailing potential hazards, critical safety measures, advanced automation, and operator best practices. It also covers regulatory standards, sustainability, and includes a comprehensive FAQ on CNC safety management.

This comprehensive article examines whether CNC machining qualifies as blue-collar work. It traces the role's history, skills, and education, highlighting its evolution into a gray-collar profession that fuses craftsmanship, technology, and digital competence in modern manufacturing.

This article explores whether CNC machining is a dying trade. It concludes that far from disappearing, CNC machining is evolving with automation, AI, and Industry 4.0 integration. The trade remains vital to global manufacturing, offering lasting opportunities for innovation and skilled careers.

This complete guide explains how to start and grow a CNC machining business — from planning, financing, and equipment selection to marketing, automation, and sustainability. Learn expert strategies to build a profitable precision manufacturing company in today's competitive market.

Explore South Korea's leading CNC Milling Services Manufacturers and Suppliers. Learn about their technology, expertise, and industries served. Ideal for OEMs, wholesalers, and partners seeking precision engineering and high-quality custom machining solutions.

Discover why Portugal is emerging as a leader among CNC Milling Services Manufacturers and Suppliers. Explore its top machining companies, precision technologies, and global OEM collaborations delivering high-quality, cost-effective components for industries worldwide.

Explore Italy's leading CNC Milling Services Manufacturers and Suppliers. Discover their technical expertise, key companies, industry capabilities, and why global OEMs rely on Italian CNC machining for precision, innovation, and long-term partnership opportunities.

An in-depth look at how CNC milling is transforming manufacturing across the Arab States. This article explores top CNC Milling Services Manufacturers and Suppliers, their technologies, challenges, partnerships, and the growing role of precision machining in regional industrial strategy.

Discover the top CNC milling services manufacturers and suppliers in France. Explore their technology, quality standards, international collaborations, and industry advantages for precision parts manufacturing and OEM production partnerships.

Explore the top 10 Prototype CNC Machining Manufacturers in China. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd., this detailed guide covers their strengths, capabilities, and why Chinese CNC machining companies lead in global innovation and precision manufacturing.

Discover the Top 10 Precision CNC Machining Manufacturers in China, highlighting their strengths, technologies, and OEM capabilities. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd. as a leader, this guide helps global buyers find reliable CNC partners for precision engineering projects.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.