From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-11 Origin: Site

Content Menu

● Understanding 3D Printing Services

>> 3. Quality Control and Precision

>> 4. Cost and Pricing Transparency

>> 5. Production Time and Delivery Reliability

>> 6. Scalability and Batch Production

>> 7. File Compatibility and Technical Support

>> 8. Customer Service and Reputation

>> 9. Data Security and Intellectual Property Protection

>> 10. Sustainability Practices

● How to Make an Informed Comparison

● FAQ

>> 1. What is the most accurate 3D printing technology?

>> 2. How do I verify the quality of a 3D printing service?

>> 3. Are metal 3D printing services more expensive?

>> 4. How can I reduce my 3D printing costs?

>> 5. Is file confidentiality guaranteed with online 3D printing services?

Choosing the right 3D printing service can significantly influence the success of a project—from initial design validation to final product delivery. The growth of additive manufacturing has led to thousands of providers offering diverse materials and technologies. For designers, engineers, and entrepreneurs, understanding how to compare 3D printing services is crucial for achieving the ideal balance between cost, precision, and production efficiency.

This guide explores everything you need to evaluate before making a final decision, including printing technologies, materials, pricing structures, customer service, and sustainability. By the end, you'll know how to analyze providers objectively and select one aligned with your technical and business needs.

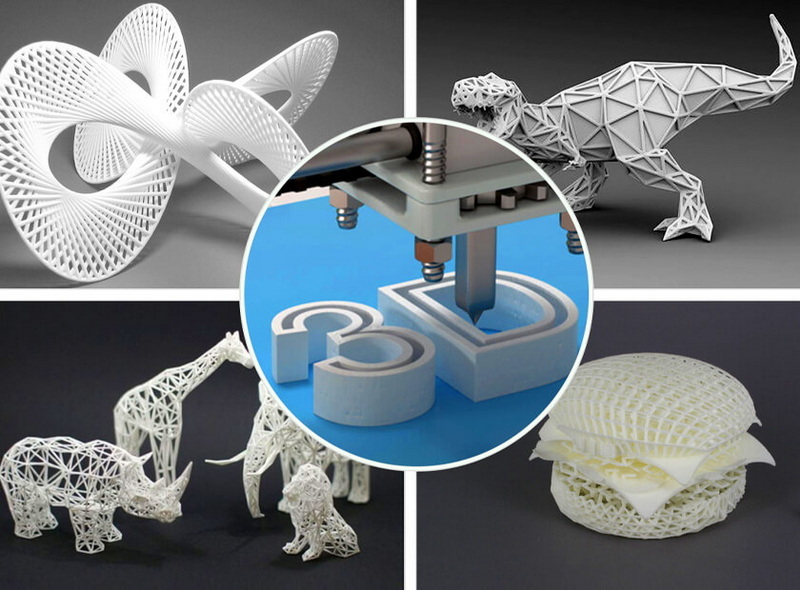

3D printing services transform digital CAD models into tangible parts by building layers of material until the design is complete. Instead of investing in your own printer fleet, you can submit a 3D file to an external provider who handles production using professional-grade equipment. These services are used for a broad range of applications—functional prototypes, replacement parts, end-use components, and even complex metal structures.

Professional 3D printing services offer advanced tools like industrial printers, certified materials, and quality control systems. They often manage post-processing, assembly, and finishing operations, ensuring usability straight out of the box. Compared with consumer-level printers, professional services deliver superior precision, strength, and consistency.

Before comparing providers, define the core purpose of your project. Are you testing design concepts, manufacturing custom medical tools, or producing market-ready parts? Clear project goals help identify which provider best meets technical expectations and production scale.

Evaluating 3D printing services requires examining a range of factors beyond raw cost. The following aspects form the foundation for intelligent selection.

The type of printing technology largely determines the quality, speed, and cost of your results. Most services specialize in one or more of these main technologies:

- FDM (Fused Deposition Modeling): Uses thermoplastic filaments melted layer by layer. It's affordable and ideal for basic prototypes or structural testing.

- SLA (Stereolithography): Uses liquid resin cured by laser for highly detailed parts with smooth surface finishes—perfect for aesthetic models.

- SLS (Selective Laser Sintering): Fuses powdered materials, usually nylon, into strong, durable functional parts without support structures.

- DMLS/SLM (Direct Metal Laser Sintering / Selective Laser Melting): Produces dense, metal parts ideal for aerospace, tooling, and high-performance industries.

- MJF (Multi Jet Fusion): Provides excellent accuracy and strength using fusing agents and infrared energy—great for functional prototypes and small-batch production.

When comparing providers, review the technologies they offer and confirm their machines' specifications such as build volume, layer thickness, and finishing capabilities.

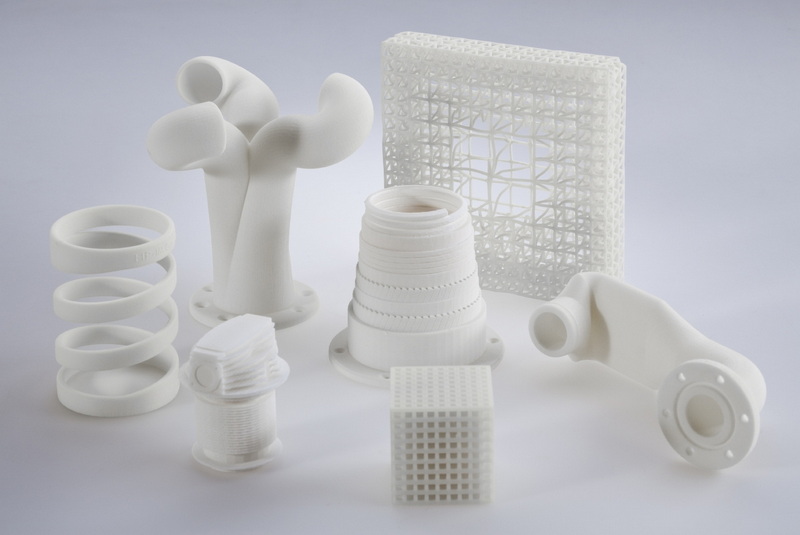

Materials determine the part's mechanical properties, weight, appearance, and durability. A well-rounded 3D printing service should offer multiple options, including:

- Plastics: PLA, ABS, PETG, and nylon for general use.

- Resins: Tough, flexible, or castable options for high-detail prototypes.

- Metals: Aluminum, stainless steel, titanium, or cobalt-chrome for industrial applications.

- Composites: Carbon fiber or glass-fiber-reinforced polymers for lightweight strength.

- Elastomers: TPU or TPE for flexible parts.

Different materials behave differently during printing and post-processing. Comparing providers based on the range and certification of materials ensures your designs are produced safely and consistently.

High-quality parts depend on stringent quality assurance. Reliable services maintain calibrated equipment and employ quality inspection protocols throughout production. This may include dimensional verification using CMM (Coordinate Measuring Machines) or 3D scanning.

Ask potential providers for sample tolerance data—often expressed as ±0.1 mm or ±0.2% of the part's dimensions. Some projects, particularly in medical or aerospace fields, require even tighter tolerances; in these cases, certification such as ISO 9001 or AS9100 is valuable.

Also, inspect the provider's post-processing services, such as sanding, vapor smoothing, painting, or polishing. These enhancements can dramatically improve aesthetics and function.

Price is important but should never be the sole deciding factor. Many services calculate prices based on:

- Material volume or weight.

- Print duration (machine hours).

- Setup or support costs.

- Post-processing operations.

- Shipping and handling.

Always request a detailed cost breakdown. Transparent pricing structures indicate professionalism and reduce the risk of hidden charges. Some providers offer instant online quote systems where you can upload your model and see live pricing updates based on material and finish choices.

However, the cheapest quote may come with trade-offs in precision or scaling. A slightly higher cost may be worth it if it guarantees smoother finishing, reliable turnaround, or superior mechanical strength.

In professional manufacturing, timing often defines success. 3D printing services advertise different lead times based on capacity, complexity, and location. Some providers deliver parts within 24–72 hours, while others may take a week or more for post-processing or large-batch orders.

When comparing providers, evaluate how lead times align with your production schedule. It's beneficial to select services offering expedited production options without compromising quality checks. Delivery reliability also depends on packaging and shipping networks—so ensure your provider partners with reputable carriers or uses local hubs.

A good 3D printing partner should handle both one-off prototypes and scalable production. Some providers specialize in low-volume manufacturing, while others integrate additive and subtractive methods to meet higher production demands.

Ask about batch printing discounts, repeatability assurance, and automated ordering processes. Reliable scalability ensures the same quality is maintained throughout production runs—something especially critical for startups transitioning from prototype to mass production.

Most providers accept popular 3D file formats like STL, STEP, OBJ, and IGES. Before submitting your model, ensure file compatibility and check for proper wall thickness, mesh closure, and orientation. Many services include automated design validation tools that catch common issues like non-manifold edges or thin walls.

Professional 3D printing providers may also offer engineering support. They can suggest design modifications for cost savings or mechanical performance improvements. This collaborative approach helps ensure your design prints correctly the first time.

The level of customer support can drastically affect your experience. Evaluate how responsive and helpful the service team is when addressing inquiries, providing updates, or resolving issues. Reliable communication minimizes errors and streamlines project coordination.

Customer reviews, industry partnerships, and case studies reveal much about a provider's reputation. A company with long-term clients across diverse industries usually indicates stability and trustworthiness.

With the increasing value of digital designs, safeguarding your 3D files is non-negotiable. Ensure your chosen provider enforces strict data security policies, encrypted file transfers, and confidentiality agreements. If confidentiality is vital, sign an NDA before sharing your design.

Some large-scale providers hold certifications like ISO 27001, proving compliance with modern data handling standards. Small providers should at least guarantee secure storage and controlled access.

Sustainability has become a deciding factor in modern manufacturing. Compare how services address environmental responsibility through:

- Recycling unused materials or failed prints.

- Using biodegradable or renewable filaments.

- Reducing waste with optimized print settings.

- Operating energy-efficient equipment.

Environmentally conscious production not only benefits the planet but also enhances a brand's social reputation. Sustainable practices often lead to more efficient use of resources, further reducing long-term costs.

Once you've gathered essential details, compile a structured comparison chart including every criterion—technology, materials, cost, precision, speed, and customer service. Weight each parameter according to project priorities; for example, medical device makers might give more weight to certifications, while a hobbyist might focus on affordability.

Sample Comparison Table:

| Criteria | Provider A | Provider B | Provider C |

|---|---|---|---|

| Technology | SLA, FDM | SLS, MJF | FDM |

| Materials | Resins, ABS, Nylon | Nylon, TPU, Aluminum | PLA, PETG |

| Precision | ±0.05 mm | ±0.1 mm | ±0.2 mm |

| Price | Moderate | Higher | Low |

| Turnaround | 3–4 days | 7 days | 2–3 days |

| Support | Excellent | Good | Basic |

From this analysis, you can visualize trade-offs among providers clearly. The best choice is the one that aligns technology, cost, and reliability with your unique project demands.

Avoid these pitfalls when comparing services:

- Choosing based on price alone. Lowest cost often means compromises in durability or finish.

- Skipping sample runs. Small test prints reveal actual quality and service reliability.

- Ignoring post-processing. Surface treatment often determines usability and appeal.

- Overlooking file preparation. Improper file setup can lead to printing errors and extra costs.

- Neglecting legal protections. Always confirm NDAs and IP protection policies before sharing designs.

Selecting the right 3D printing service requires balancing technology, precision, delivery speed, and cost against your project's requirements. The best provider acts not only as a manufacturer but also as a partner that supports you from file optimization to post-processing. Whether you are producing prototypes or scaling full production runs, thorough comparison guarantees better quality, fewer delays, and more value for every dollar spent.

By focusing on transparency, reliability, and certification, you ensure that your chosen provider transforms your designs into high-quality physical parts while preserving confidentiality and manufacturing integrity. In a rapidly growing industry, informed decision-making remains your strongest competitive advantage.

SLA and DLP technologies are renowned for their high accuracy and smooth surface finish, making them ideal for jewelry, dental models, and fine-detail prototypes.

Look for ISO-certified facilities, request sample prints, and review dimensional inspection reports. Quality-driven services also perform automated part checks.

Yes. Technologies like DMLS and SLM are costlier due to material price, equipment complexity, and post-processing needs, but they deliver unmatched strength and thermal performance.

Optimize your design to minimize support material, use in-fill strategies, and select cost-effective materials suited for your part's function rather than aesthetics alone.

Reputable companies use secure servers and offer NDAs to ensure confidentiality. For sensitive designs, choose providers certified in data security management.

Is CNC machining expensive? This detailed guide breaks down every factor influencing CNC cost—from materials and machine time to tolerances and production volume—while offering expert strategies to reduce expenses and maximize manufacturing efficiency.

This in-depth article explores whether CNC machining is dangerous, detailing potential hazards, critical safety measures, advanced automation, and operator best practices. It also covers regulatory standards, sustainability, and includes a comprehensive FAQ on CNC safety management.

This comprehensive article examines whether CNC machining qualifies as blue-collar work. It traces the role's history, skills, and education, highlighting its evolution into a gray-collar profession that fuses craftsmanship, technology, and digital competence in modern manufacturing.

This article explores whether CNC machining is a dying trade. It concludes that far from disappearing, CNC machining is evolving with automation, AI, and Industry 4.0 integration. The trade remains vital to global manufacturing, offering lasting opportunities for innovation and skilled careers.

This complete guide explains how to start and grow a CNC machining business — from planning, financing, and equipment selection to marketing, automation, and sustainability. Learn expert strategies to build a profitable precision manufacturing company in today's competitive market.

Explore South Korea's leading CNC Milling Services Manufacturers and Suppliers. Learn about their technology, expertise, and industries served. Ideal for OEMs, wholesalers, and partners seeking precision engineering and high-quality custom machining solutions.

Discover why Portugal is emerging as a leader among CNC Milling Services Manufacturers and Suppliers. Explore its top machining companies, precision technologies, and global OEM collaborations delivering high-quality, cost-effective components for industries worldwide.

Explore Italy's leading CNC Milling Services Manufacturers and Suppliers. Discover their technical expertise, key companies, industry capabilities, and why global OEMs rely on Italian CNC machining for precision, innovation, and long-term partnership opportunities.

An in-depth look at how CNC milling is transforming manufacturing across the Arab States. This article explores top CNC Milling Services Manufacturers and Suppliers, their technologies, challenges, partnerships, and the growing role of precision machining in regional industrial strategy.

Discover the top CNC milling services manufacturers and suppliers in France. Explore their technology, quality standards, international collaborations, and industry advantages for precision parts manufacturing and OEM production partnerships.

Explore the top 10 Prototype CNC Machining Manufacturers in China. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd., this detailed guide covers their strengths, capabilities, and why Chinese CNC machining companies lead in global innovation and precision manufacturing.

Discover the Top 10 Precision CNC Machining Manufacturers in China, highlighting their strengths, technologies, and OEM capabilities. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd. as a leader, this guide helps global buyers find reliable CNC partners for precision engineering projects.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.