From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-10 Origin: Site

Content Menu

● General Applications of CNC Milling

>> 1. Prototyping and Product Development

>> 2. Custom and Low-Volume Manufacturing

>> 3. Mass Production of Precision Parts

>> 4. Tooling, Dies, and Mold Manufacturing

>> 5. Engraving and Surface Detailing

● CNC Milling in Different Industries

● Types of CNC Milling Machines

>> 3-Axis Mills

>> 4-Axis Mills

>> 5-Axis Mills

>> Vertical and Horizontal Layouts

● Common CNC Milling Operations

● Materials Used in CNC Milling

● Tolerances and Surface Finishing

● Advances in CNC Milling Technology

● Environmental Considerations

>> 1. What materials can be machined using CNC milling?

>> 2. Which industries rely most heavily on CNC milling?

>> 3. How accurate is CNC milling compared to other methods?

>> 4. What's the difference between CNC milling and turning?

>> 5. Is CNC milling cost-effective for small quantities?

Computer Numerical Control (CNC) milling is one of the most significant technologies in modern manufacturing. This computer-driven machining process uses rotating, multi-point cutting tools to remove material from a workpiece, creating parts with highly accurate dimensions and complex geometries. Its ability to deliver precision, consistency, and repeatability has redefined what manufacturers can achieve across industries. From simple prototypes to intricate aerospace components, CNC milling provides the precision and flexibility needed in today's high-performance world.

CNC milling is a subtractive manufacturing process, meaning it crafts a final part by removing material from a solid block — often metal, plastic, or composite. Instead of relying on manual operation, a CNC mill follows precise digital commands from a design file. These commands, written in G-code, instruct the machine on speed, movement, and tool paths to cut a workpiece accurately.

A typical CNC milling machine operates along multiple axes:

- X, Y, and Z axes control horizontal, cross, and vertical movements.

- Rotational axes (A and B) allow the tool or workpiece to rotate, enabling complex angle cuts.

By integrating CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems, CNC milling turns virtual designs into physical components with microscopic precision. These systems ensure every part is produced identically, no matter how many times it's made.

CNC milling is typically performed in several core steps:

1. Design Stage: Engineers create a digital 3D model using CAD software. This file defines the shape, dimensions, and features of the part.

2. Toolpath Generation: CAM software transforms the model into machine-readable G-code that dictates the exact trajectory of the cutting tools.

3. Machine Setup: The machinist installs cutting tools, mounts the material, and calibrates the machine.

4. Machining: The mill removes material in programmed layers or passes, often switching between multiple tools for different operations.

5. Finishing and Inspection: The part undergoes inspection using coordinate measuring machines (CMMs) to verify accuracy. If necessary, surface finishing, deburring, or coating follows.

The result is a component that precisely matches its digital blueprint, often with tolerances down to microns.

CNC milling's adaptability gives it near-limitless applications. It is used wherever complex shapes, fine tolerances, or repeatable high-volume production are required.

CNC milling is indispensable in the early stages of product innovation. Designers can quickly produce accurate, functional prototypes that match real production quality. This allows immediate testing of performance, assembly compatibility, and aesthetic evaluation before mass manufacturing begins, saving both time and resources.

In sectors where components must be custom-designed, CNC milling provides unmatched flexibility. Whether producing specialized jigs, fixtures, or one-of-a-kind mechanical assemblies, it allows quick adaptation to design changes without expensive retooling.

For industries requiring thousands or millions of identical components, CNC milling ensures repeatability and tight quality control. Advanced machines equipped with robotic part loading can operate 24/7, significantly improving productivity.

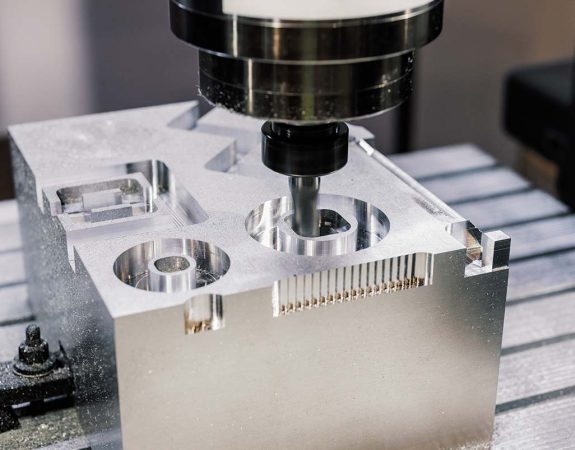

CNC milling helps create high-precision molds and dies used for injection molding, metal forming, and casting. Tough materials like hardened steel, titanium, or carbide can be machined with superior surface finishes, extending tool life and ensuring flawless product quality.

Engraving names, serial numbers, or logos on parts is another everyday use. In industries like jewelry, firearms, and luxury goods, CNC milling achieves remarkable fine detailing with consistent depth and smoothness.

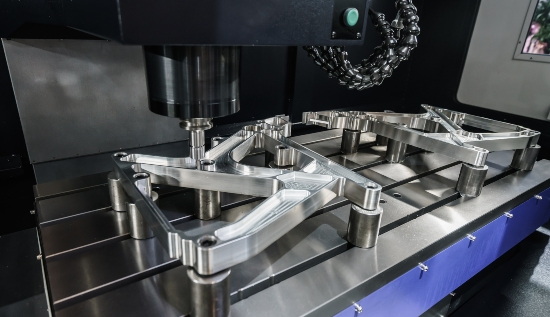

CNC milling plays a crucial role in producing lightweight yet strong structures such as airframe ribs, brackets, and engine components. Given the strict safety and performance standards, the aerospace industry relies on five-axis CNC milling to create intricate surfaces that optimize aerodynamics and fuel efficiency.

From high-performance engine blocks to precision interior fittings, automotive manufacturers use CNC milling to prototype and mass-produce tight-tolerance parts. It also assists in fabricating molds for plastic and composite car components, allowing designers to experiment with lightweight materials.

Precision underpins the medical field. CNC mills manufacture orthopedic implants, dental fixtures, surgical tools, and prosthetic components, often out of titanium or medical-grade stainless steel. Because patient safety is paramount, machining must ensure sterility, surface smoothness, and accuracy within microns.

Consumer electronics demand miniature, accurate housings and connectors. CNC milling produces components like heat sinks, circuit board frames, and aluminum casings with exact alignment. Its precision makes it essential for creating parts that must fit together seamlessly on assembly lines.

In defense, CNC mills produce components for radar systems, missiles, and armored vehicles requiring strength and dimensional precision. In the energy sector, they help create turbines, compressors, and complex fittings for oil, gas, and nuclear systems where reliability can mean operational safety.

The reasons for CNC milling's dominance in manufacturing extend beyond precision. Its main advantages include:

- Consistency: Every part produced is identical to the digital file, minimizing human error.

- Efficiency: Automated systems operate continuously, reducing lead time.

- Flexibility: Can machine multiple materials and geometries.

- Complexity: Capable of crafting shapes impossible with manual machining.

- Reduced Waste: Smart toolpaths and optimized programming minimize scrap.

- Scalability: Easily adapted for both prototype and mass production.

Moreover, milling often integrates with other technologies like laser scanning or additive manufacturing, creating hybrid systems that expand design potential.

The standard 3-axis configuration (X, Y, Z) covers vertical and horizontal movements—ideal for simpler geometries such as plates, covers, and standard housings.

These machines introduce a rotational axis, permitting the milling of multiple sides without remounting. They are especially useful for cylindrical parts or when engraving designs along a circular surface.

The most advanced configuration allows both the tool and the workpiece to rotate simultaneously, machining highly contoured shapes in a single setup. This is indispensable for producing complex blades, prosthetics, and aircraft components where exact curvature matters.

- Vertical Milling: A vertically oriented spindle offers excellent accuracy for smaller, detailed workpieces.

- Horizontal Milling: The spindle lies horizontally, perfect for removing large amounts of material or producing heavy parts.

Several distinct operations can be performed in a CNC milling process:

- Face Milling: Removes material to create flat surfaces or smooth finishes.

- Peripheral Milling: Cuts along the outside edges for contours and profiles.

- Slot and Pocket Milling: Produces slots, recesses, or cavities.

- Drilling and Boring: For holes and cylindrical features with high alignment accuracy.

- Thread Milling: Creates precise screw threads on multiple diameters.

- Contour and 3D Milling: Used for sculpted shapes in dies, molds, or artistic pieces.

These operations may occur in sequence or simultaneously depending on the tool path strategy and machine type.

A key strength of CNC milling lies in its adaptability to various materials, including:

- Aluminum: Lightweight and corrosion-resistant for automotive and electronics.

- Steel and Stainless Steel: Used in heavy-duty and structural applications.

- Titanium: Valued in aerospace and medical implants for strength-to-weight ratio.

- Brass and Copper: Common in electrical and decorative components due to conductivity.

- Engineering Plastics: ABS, PEEK, and Delrin used for insulation and lightweight parts.

- Composites and Carbon Fiber: Increasingly used in aerospace and sporting industries.

Each material requires optimized tool speeds, feeds, and cooling systems to maintain surface finish and accuracy.

CNC milling can achieve tolerances as tight as ±0.001 inches (0.025 mm). However, tolerances depend on the material, machine condition, and part complexity. After milling, additional finishing processes such as polishing, anodizing, or coating improve appearance, corrosion resistance, or wear performance.

High-end parts like aerospace brackets or medical implants often undergo multi-stage verification, including coordinate measurement and optical scanning, to guarantee conformance with digital models.

Modern CNC milling machines incorporate innovations that enhance precision, efficiency, and automation:

- High-Speed Machining (HSM): Enables faster cutting with minimal heat buildup.

- IoT and Smart Factories: Machines communicate with central systems for real-time data monitoring.

- Automatic Tool Changers (ATC): Allow seamless switching between tools, reducing downtime.

- Adaptive Control Systems: Software adjusts cutting parameters automatically based on feedback.

- Hybrid Manufacturing: Combines CNC milling with additive techniques like 3D printing for increased flexibility.

These innovations continue to evolve CNC milling into a fully digital, intelligent ecosystem where humans and machines collaborate seamlessly.

Modern manufacturing must also consider sustainability. CNC milling helps reduce waste through:

- High material utilization—optimized paths leave minimal scrap.

- Energy-efficient machines using servo motors and regenerative drives.

- Coolant recycling systems that minimize fluid waste.

Moreover, digital simulation before machining reduces trial runs and rejects, contributing to a smaller environmental footprint.

CNC milling has evolved from a mechanical process to a digitally integrated system central to global production. Its precision, flexibility, and reliability make it indispensable for industries demanding exact dimensions and durability. Whether crafting an aerospace turbine, a medical implant, or a custom prototype, CNC milling ensures consistency and perfection from start to finish. As automation, AI, and real-time monitoring technologies advance, the role of CNC milling will only grow, pushing the boundaries of design and functionality in the manufacturing world.

CNC milling can handle a wide range of materials such as aluminum, steel, titanium, brass, copper, and plastics. Selection depends on strength, conductivity, and application requirements.

Industries including aerospace, automotive, medical, defense, and electronics rely on CNC milling for creating precise, complex, and reliable components.

CNC milling achieves extremely tight tolerances—down to ±0.001 inches—outperforming manual machining and ensuring repeatability across entire production runs.

Milling removes material with a rotating tool and stationary workpiece, while turning rotates the workpiece against a stationary cutting tool. Each serves different geometries—milling for flat or complex parts, turning for cylindrical shapes.

Yes. CNC milling's digital control eliminates tooling costs, making it efficient and affordable for prototypes, custom parts, or low-volume batches where accuracy still matters.

Explore South Korea's leading CNC Milling Services Manufacturers and Suppliers. Learn about their technology, expertise, and industries served. Ideal for OEMs, wholesalers, and partners seeking precision engineering and high-quality custom machining solutions.

Discover why Portugal is emerging as a leader among CNC Milling Services Manufacturers and Suppliers. Explore its top machining companies, precision technologies, and global OEM collaborations delivering high-quality, cost-effective components for industries worldwide.

Explore Italy's leading CNC Milling Services Manufacturers and Suppliers. Discover their technical expertise, key companies, industry capabilities, and why global OEMs rely on Italian CNC machining for precision, innovation, and long-term partnership opportunities.

An in-depth look at how CNC milling is transforming manufacturing across the Arab States. This article explores top CNC Milling Services Manufacturers and Suppliers, their technologies, challenges, partnerships, and the growing role of precision machining in regional industrial strategy.

Discover the top CNC milling services manufacturers and suppliers in France. Explore their technology, quality standards, international collaborations, and industry advantages for precision parts manufacturing and OEM production partnerships.

Explore the top 10 Prototype CNC Machining Manufacturers in China. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd., this detailed guide covers their strengths, capabilities, and why Chinese CNC machining companies lead in global innovation and precision manufacturing.

Discover the Top 10 Precision CNC Machining Manufacturers in China, highlighting their strengths, technologies, and OEM capabilities. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd. as a leader, this guide helps global buyers find reliable CNC partners for precision engineering projects.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.

Learn how to post 3D printing services professionally with this comprehensive guide. Discover key steps for building an online presence, optimizing listings, managing orders, pricing smartly, and staying competitive in the fast-growing 3D printing market.

This extended guide explains how to market a 3D printing service through branding, SEO, content creation, social media, partnerships, and client experience. It provides actionable marketing strategies to build trust, improve visibility, and drive growth in a competitive 3D printing industry.

This comprehensive guide explains how to compare 3D printing services by analyzing key aspects such as technology options, materials, quality control, pricing transparency, delivery time, scalability, and security. It helps readers choose reliable providers for both prototypes and production parts.

An in-depth guide to choosing the right 3D printing service. Learn to evaluate technologies, materials, quality standards, and pricing. Perfect for engineers, designers, and entrepreneurs seeking reliable, precise, and cost-effective 3D printing solutions.

Discover how to effectively advertise 3D printing services using SEO, social media, paid campaigns, and branding. This comprehensive guide explains proven marketing strategies to grow your audience, attract clients, and build authority in the evolving 3D printing industry.