From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-14 Origin: Site

Content Menu

● Understanding CNC Milling and Its Industrial Significance

● The Rise of Industrial Modernization in the Arab States

● Core Capabilities of Leading CNC Milling Providers

● Key CNC Milling Centers in the Arab Region

>> Saudi Arabia

>> Qatar

● Choosing the Right CNC Milling Partner

● OEM and ODM Advantages for Global Brands

● China–Arab Industrial Cooperation

● Technological Trends Shaping the CNC Industry

● Training, Talent, and Workforce Development

● Challenges Facing CNC Milling Manufacturers

● Opportunities and Future Outlook

● Frequently Asked Questions (FAQ)

>> Q1: Which countries in the Arab region lead CNC milling production?

>> Q3: Can Arab CNC manufacturers handle high-volume orders for global brands?

>> Q4: What makes CNC milling essential for modern industries?

>> Q5: How is digital transformation influencing Arab CNC industries?

The Arab States have rapidly emerged as a key hub for modern manufacturing, blending industrial innovation with advanced technology. Among various industrial processes driving this transformation, CNC milling services stand out for their precision, versatility, and scalability. Today, businesses across the Middle East and North Africa are increasingly relying on professional CNC Milling Services Manufacturers and Suppliers to produce high-quality parts and components that meet global standards.

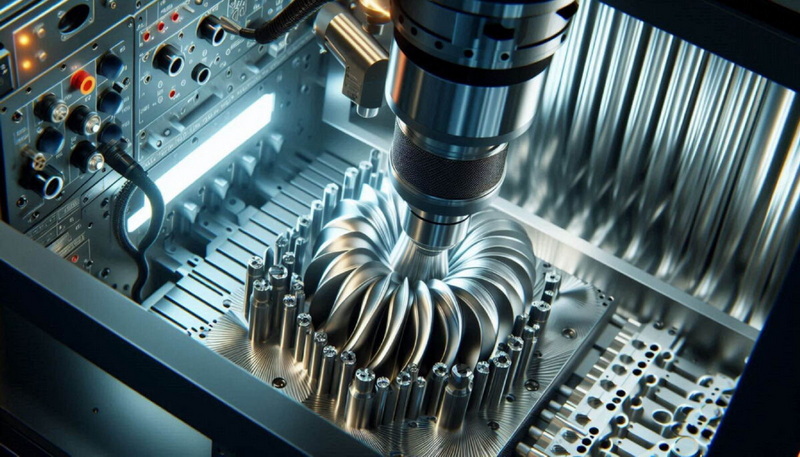

CNC (Computer Numerical Control) milling is a computer-driven process that removes material from raw workpieces through automated cutting tools. Using CAD/CAM software, CNC milling enables precise, repeatable designs that can achieve complex geometries impossible with manual machining.

This method is widely used in industries where precision and quality directly affect product performance—such as aerospace, automotive, oil & gas, defense, medical, energy, robotics, and marine engineering. The ability to machine metals, plastics, and composite materials with micron-level accuracy makes CNC milling indispensable in today's global supply chains.

CNC Milling Services Manufacturers and Suppliers provide advanced solutions including prototyping, mass production, and custom part design. They support global brands and regional factories with end-to-end manufacturing services that improve efficiency while reducing operational costs.

In recent decades, Arab economies have undergone strategic diversification. National visions such as Saudi Vision 2030, UAE Industrial Strategy 2031, and Qatar National Vision 2030 emphasize reducing dependence on oil by developing strong manufacturing and technology sectors. This drive for self-reliance has made high-precision machining and CNC Milling Services Manufacturers and Suppliers essential to industrial growth.

Countries such as the United Arab Emirates, Saudi Arabia, Qatar, Bahrain, and Oman have built industrial free zones and technology parks that attract international investors. These facilities host specialized machining centers equipped with multi-axis CNC milling machines, automated inspection systems, and CAD/CAM integration. The result is a thriving ecosystem that blends local capacity with international expertise.

Top CNC Milling Services Manufacturers and Suppliers in the Arab States exhibit several strengths that enhance their competitiveness on the global stage:

1. High-tech Equipment and Automation – State-of-the-art CNC machines from brands like DMG Mori, Mazak, and Haas ensure consistent performance and tight tolerances. Many facilities use 5-axis systems for superior flexibility.

2. Expert Engineering Teams – Skilled engineers with deep experience in mechanical design, materials science, and production planning help streamline operations.

3. Robust Quality Assurance – Advanced inspection systems such as coordinate measuring machines (CMMs) and laser scanners ensure every part meets international quality benchmarks.

4. Wide Material Compatibility – CNC milling supports metals such as aluminum, steel, brass, and titanium, as well as plastic and composite materials for lightweight applications.

5. Prototype-to-Production Scalability – Whether producing a single prototype or thousands of identical components, these companies maintain precision and repeatability.

Through these capabilities, Arab region suppliers can meet stringent client demands across sectors ranging from renewable energy to aerospace.

The UAE remains a regional powerhouse for advanced manufacturing. In Dubai and Abu Dhabi, industrial hubs such as Dubai Industrial City and Khalifa Industrial Zone (KIZAD) host numerous CNC Milling Services Manufacturers and Suppliers serving international clients. The country's exceptional logistics, air-sea connectivity, and zero-import tariffs on machinery encourage global buyers to partner with local CNC providers.

Moreover, the UAE's active collaboration with Chinese, European, and American OEMs helps upgrade local technical capabilities. Aerospace, shipbuilding, and automotive industries particularly benefit from these high-precision facilities.

Under Vision 2030, Saudi Arabia is investing heavily in industrial diversification. The expansion of the King Salman Energy Park (SPARK) and Jubail Industrial City supports an ecosystem of machining and component manufacturing companies. Saudi CNC Milling Services Manufacturers and Suppliers specialize in oilfield tools, precision valves, vehicle components, and heavy industrial parts.

The government encourages international partnerships to bring cutting-edge CNC technology to local manufacturers while training Saudi technicians in advanced production methods.

Qatar's industrial sector has undergone rapid modernization since the early 2010s. Today, Doha hosts several CNC Milling Services Manufacturers and Suppliers supporting high-value projects in the energy, construction, and logistics sectors. Companies focus on producing components for LNG infrastructure and aerospace parts, leveraging the nation's advanced research centers.

The country's proactive approach to manufacturing education and innovation helps position Qatar as one of the most technically advanced producers in the Gulf region.

Although smaller, Bahrain and Oman have developed agile, cost-effective machining industries. Supported by skilled labor forces, these nations focus on custom CNC production and regional exports. Their geographic position near key shipping routes gives them an advantage in serving the wider Middle East and African markets.

Their CNC Milling Services Manufacturers and Suppliers often excel in small-batch production, marine components, and precision tooling, offering competitive alternatives to large-scale producers.

Selecting the ideal CNC manufacturer involves considering technology, expertise, and reliability. Here's how to evaluate CNC Milling Services Manufacturers and Suppliers before committing:

- Review Technical Capability: Ensure they can handle your specifications, tolerances, and materials. Multi-axis machines are advantageous for complex designs.

- Check Quality Certification: Reputable suppliers carry ISO 9001, AS9100, or TS16949 certifications demonstrating commitment to quality processes.

- Request Sample Work: Before mass production, request prototype samples to verify accuracy and finish.

- Assess Communication and Support: Timely updates, project transparency, and responsive customer service are crucial for long-term collaboration.

- Compare Lead Times and Costs: Efficient workflow management ensures shorter turnaround without compromising precision.

When businesses choose reliable partners with a balanced focus on precision, flexibility, and service, they gain operational continuity and product consistency.

Arab CNC Milling Services Manufacturers and Suppliers frequently act as OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) partners for international clients. These full-service solutions include design consultation, rapid prototyping, component testing, packaging, and logistics coordination.

Manufacturers collaborate closely with clients to refine product geometries for better manufacturability, enhance performance through design optimization, and ensure every component conforms to strict quality guidelines. This model allows global brands to enjoy both reduced costs and localized production advantages.

For example, an OEM automotive supplier in Saudi Arabia can design and mill aluminum engine housings locally, cutting import times while maintaining European-level quality. Similarly, aerospace component producers in the UAE can rapidly prototype parts for international clients, integrating additive manufacturing and CNC finishing for superior precision.

China has become a vital strategic partner for Arab manufacturing modernization. Chinese CNC Milling Services Manufacturers and Suppliers bring decades of expertise in precision machining and offer cost-effective solutions to partner factories in the Middle East. The cooperation extends beyond simple trade—it includes technology transfer, joint ventures, and workforce training programs.

By establishing shared production lines or technical partnerships, Chinese and Arab companies can streamline regional supply chains. For instance, raw parts may be produced in China and then customized or assembled in the Arab States, minimizing lead time and shipping costs. This model strengthens both economies while improving global competitiveness.

The CNC industry in the Arab region is embracing digital transformation through Industry 4.0 practices. Automation, artificial intelligence, and IoT (Internet of Things) integration are redefining machining processes. Modern CNC Milling Services Manufacturers and Suppliers now rely on advanced digital monitoring systems to enhance efficiency.

- Smart Machines: Real-time data sensors track temperature, vibration, and cutting forces to improve predictive maintenance.

- Digital Twin Technology: Virtual simulation models mirror live production systems to optimize performance before machining begins.

- Automated Tool Management: Software-controlled systems reduce downtime and increase productivity.

- Sustainable Manufacturing: Many shops are switching to eco-friendly lubricants, energy-efficient machinery, and recyclable materials to meet environmental goals.

These innovations are helping Arab manufacturers meet the growing global demand for precision parts without sacrificing environmental responsibility or production agility.

The availability of skilled machinists and engineers determines a country's manufacturing success. Arab States are investing in technical institutes, vocational training centers, and international exchange programs to foster expertise in mechanical engineering and automation.

Collaborations between universities and CNC Milling Services Manufacturers and Suppliers help bridge the skills gap. Students learn programming tools such as G-code and gain hands-on experience operating multi-axis machines, preparing them for the future of high-precision industries.

Although opportunities are plentiful, the industry still faces certain constraints:

1. Dependence on Imported Raw Materials – Many manufacturers still source metals and alloys from Asia or Europe, adding cost and time.

2. Limited Domestic R&D – Developing proprietary toolpath optimization and machine software remains a long-term challenge.

3. High Equipment Investment Costs – Acquiring and maintaining 5-axis CNC machines demands significant financial resources.

4. Competition from Asian Suppliers – While quality in the Arab region grows rapidly, price-sensitive clients sometimes prefer established Asian partners.

However, ongoing government incentives, digital transformation, and cross-border cooperation with China and Europe are helping local companies close these gaps effectively.

Looking ahead, the region's CNC Milling Services Manufacturers and Suppliers are poised for tremendous growth thanks to continued foreign investment, supportive policy frameworks, and expanding regional trade.

As energy diversification and green technology spread, industries will increasingly need CNC-machined parts for wind turbines, hydrogen systems, and electric vehicles. Aerospace maintenance hubs in Dubai, Jeddah, and Doha are already boosting demand for certified machining services capable of meeting Airbus and Boeing specifications.

Moreover, new public-private partnerships (PPPs) will likely promote knowledge transfer, sustainable manufacturing, and smart factory adoption. By combining innovation with high-quality production standards, the Arab States are positioning themselves as the next global machining powerhouse.

The remarkable rise of CNC Milling Services Manufacturers and Suppliers in the Arab States reflects a broader industrial shift toward technological excellence and economic diversification. Supported by digital infrastructure, international partnerships, and a skilled emerging workforce, the CNC milling sector is shaping the region's next industrial era.

From precision aerospace components in Abu Dhabi to oilfield tools in Saudi Arabia and custom prototypes in Qatar, CNC milling is now central to Arab manufacturing identity. As innovation accelerates and cross-border cooperation deepens, the Arab States are well positioned to become one of the world's most advanced and reliable hubs for precision machining.

A1: The United Arab Emirates and Saudi Arabia currently lead, followed by Qatar, Oman, and Bahrain, all of which have growing capacities and modern infrastructure.

Q2: How are quality standards maintained by CNC Milling Services Manufacturers and Suppliers in the region?

A2: Through ISO certification, precision inspection systems, material traceability, and process documentation that align with international standards.

A3: Yes. Many operate advanced production lines capable of both low-volume prototyping and high-volume batch manufacturing with consistent quality.

A4: CNC milling ensures accuracy, repeatability, and flexibility—allowing manufacturers to produce intricate parts that manual machining cannot replicate.

A5: The integration of AI, digital twins, and IoT technologies enhances efficiency, reduces downtime, and supports predictive maintenance in machining facilities.

Explore South Korea's leading CNC Milling Services Manufacturers and Suppliers. Learn about their technology, expertise, and industries served. Ideal for OEMs, wholesalers, and partners seeking precision engineering and high-quality custom machining solutions.

Discover why Portugal is emerging as a leader among CNC Milling Services Manufacturers and Suppliers. Explore its top machining companies, precision technologies, and global OEM collaborations delivering high-quality, cost-effective components for industries worldwide.

Explore Italy's leading CNC Milling Services Manufacturers and Suppliers. Discover their technical expertise, key companies, industry capabilities, and why global OEMs rely on Italian CNC machining for precision, innovation, and long-term partnership opportunities.

An in-depth look at how CNC milling is transforming manufacturing across the Arab States. This article explores top CNC Milling Services Manufacturers and Suppliers, their technologies, challenges, partnerships, and the growing role of precision machining in regional industrial strategy.

Discover the top CNC milling services manufacturers and suppliers in France. Explore their technology, quality standards, international collaborations, and industry advantages for precision parts manufacturing and OEM production partnerships.

Explore the top 10 Prototype CNC Machining Manufacturers in China. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd., this detailed guide covers their strengths, capabilities, and why Chinese CNC machining companies lead in global innovation and precision manufacturing.

Discover the Top 10 Precision CNC Machining Manufacturers in China, highlighting their strengths, technologies, and OEM capabilities. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd. as a leader, this guide helps global buyers find reliable CNC partners for precision engineering projects.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.

Learn how to post 3D printing services professionally with this comprehensive guide. Discover key steps for building an online presence, optimizing listings, managing orders, pricing smartly, and staying competitive in the fast-growing 3D printing market.

This extended guide explains how to market a 3D printing service through branding, SEO, content creation, social media, partnerships, and client experience. It provides actionable marketing strategies to build trust, improve visibility, and drive growth in a competitive 3D printing industry.

This comprehensive guide explains how to compare 3D printing services by analyzing key aspects such as technology options, materials, quality control, pricing transparency, delivery time, scalability, and security. It helps readers choose reliable providers for both prototypes and production parts.

An in-depth guide to choosing the right 3D printing service. Learn to evaluate technologies, materials, quality standards, and pricing. Perfect for engineers, designers, and entrepreneurs seeking reliable, precise, and cost-effective 3D printing solutions.

Discover how to effectively advertise 3D printing services using SEO, social media, paid campaigns, and branding. This comprehensive guide explains proven marketing strategies to grow your audience, attract clients, and build authority in the evolving 3D printing industry.