From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-14 Origin: Site

Content Menu

● 1. Overview of the CNC Milling Industry in France

● 2. Core Technologies and Capabilities of French CNC Milling Providers

>> 2.1 Advanced Multi-Axis CNC Milling

>> 2.2 Real-Time Process Monitoring

>> 2.3 Surface Finishing and Post-Processing

● 3. Leading CNC Milling Services Manufacturers and Suppliers in France

>> 3.2 SNECMA (Safran Aircraft Engines)

>> 3.5 Precise Industries France

● 4. Strengths of Working with French CNC Milling Services

>> 4.1 Premium Quality and Reliability

>> 4.3 Sustainable Manufacturing

>> 4.4 Supply Chain Resilience

● 5. The Role of Chinese OEM Partners in Global CNC Supply Chains

● 6. Industries Served by French CNC Milling Companies

● 7. Quality Control and Certification in the French CNC Sector

● 8. Factors to Consider When Choosing a CNC Milling Partner in France

● 9. Emerging Trends Shaping the Future of CNC Milling in France

>> 9.1 Artificial Intelligence and Predictive Maintenance

>> 9.2 Additive and Subtractive Hybrid Manufacturing

>> 9.3 Data-Driven Production Analytics

>> Q1: What are the main advantages of using French CNC milling suppliers?

>> Q2: Which sectors rely most on CNC milling services in France?

>> Q3: Do French CNC companies offer custom OEM services?

>> Q4: Can international clients work remotely with French CNC firms?

>> Q5: How do French suppliers maintain competitive pricing?

>> Q6: What certifications do French CNC manufacturers usually have?

>> Q7: What machining tolerances can be achieved?

France is recognized worldwide for its sophisticated manufacturing infrastructure, advanced engineering capabilities, and dedication to precision craftsmanship. Within this industrial landscape, CNC milling services manufacturers and suppliers hold an especially important place. They provide the technical backbone for French industries such as aerospace, automotive, defense, energy, medical devices, and electronics—sectors that demand perfect accuracy and consistency in high-value parts.

As global competition intensifies, CNC milling companies in France are not only enhancing their domestic capabilities but also integrating supply-chain collaborations with global partners, including Asian OEM specialists. These partnerships allow them to maintain European quality standards while optimizing production costs and efficiency for international clients.

The evolution of CNC (Computer Numerical Control) manufacturing has fundamentally changed the way French companies approach mechanical production. Over the years, the French industry has adopted automation, artificial intelligence, and digital twin systems to ensure higher accuracy, better productivity, and lower wastage.

Today, France stands among Europe's leading destinations for CNC milling services manufacturers and suppliers, offering end-to-end production support—from part design and prototyping to large-scale manufacturing and final assembly.

A few key highlights of the French CNC industry include:

- Continuous investment in smart factory ecosystems.

- Focus on zero-defect manufacturing through digital tracking.

- Emphasis on environmentally sustainable and energy-efficient operations.

- Global certifications such as ISO 9001, AS9100, and IATF 16949.

These elements make France not just a supplier nation but an industrial partner for high-precision global manufacturing.

French CNC milling services manufacturers and suppliers are known for their strong engineering foundations and advanced machining setups.

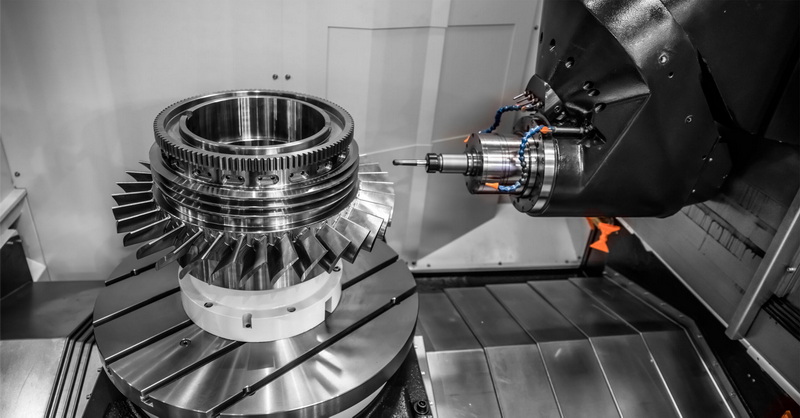

Many French companies specialize in 3-, 4-, and 5-axis CNC milling. Multi-axis technology allows for complex geometries, undercuts, and intricate surface contours to be machined without repositioning the part, significantly improving precision and efficiency.

Smart manufacturing systems now enable remote monitoring of machine performance. In France, Industry 4.0 integration allows engineers to track spindle speed, feed rate, and temperature using IoT sensors, ensuring consistent product quality and predictive maintenance capabilities.

After milling, most French suppliers offer secondary operations such as sandblasting, anodizing, polishing, and powder coating. These processes enhance durability, appearance, and corrosion resistance—essential for industries such as marine and aerospace.

CNC professionals in France have expertise in machining materials ranging from lightweight aluminum 6061 and high-grade stainless steel to titanium, brass, copper, and composite polymers. This versatility allows them to serve clients across diverse technical sectors.

Below are prominent companies that represent the strength of France's CNC milling sector. Each contributes uniquely through specialization, global collaboration, and technological sophistication.

Groupe Mecachrome, headquartered in Amboise, is one of Europe's most influential precision machining groups. Its modern facilities are equipped with automated milling centers that cater to aerospace, automotive, and energy markets. The company's advanced dimensional control systems ensure tolerances within microns, meeting the stringent requirements of Airbus, Safran, and Renault.

Part of the larger Safran Group, SNECMA is central to France's aerospace industry. Its CNC milling operations focus on manufacturing turbine disks, blade components, and other precision engine parts. Their approach exemplifies France's marriage of innovation, safety, and sustainability, integrating digital twins to simulate every machining step.

Daher operates several CNC milling centers focused on aerospace and defense parts production. Using 5-axis machining and data-driven control, Daher delivers small-series prototypes and large-batch production with tight dimensional accuracy. It also invests heavily in energy-efficient production systems that align with EU environmental goals.

Known for their materials expertise, Aubert & Duval specializes in hard-to-machine alloys and custom components. In addition to forging and heat treatment, they perform milling operations with extreme tolerance precision for power-generation equipment and airframe components. Their research collaboration with universities reinforces their technological leadership.

This fast-developing SME is a model of modern digital manufacturing. It provides contract CNC milling services for medical instrument developers, micro-electronic device manufacturers, and automation system integrators. By combining French design expertise with efficient multi-machine production, Precise Industries ensures cost-effective, on-demand solutions.

Located in southwestern France, Figeac Aero is a highly automated plant dedicated to aerospace machining. Using integrated ERP and MES systems, its precision milling services produce components for aviation giants like Boeing and Airbus. The facility's traceability system ensures that every component meets international certification requirements.

Business partnerships with French CNC milling services manufacturers and suppliers offer strategic advantages that go beyond technical capability. France's industrial culture emphasizes collaboration, long-term planning, and transparency.

French machining companies maintain strict adherence to EU regulations and quality protocols. They conduct ongoing calibration checks, simulate tool wear, and use laser alignment for consistent quality assurance.

The integration of research and industry is a hallmark of French manufacturing. CNC suppliers often collaborate with universities and national research centers to explore new materials, milling tools, and automation algorithms.

France's commitment to the European Green Deal has encouraged machining companies to reduce carbon footprints. Many suppliers use recycled coolants, solar-powered facilities, and AI-driven optimization to save energy during milling operations.

French CNC suppliers maintain robust relationships with steelmakers, logistics partners, and surface-treatment vendors across Europe, ensuring stable availability of materials and fast turnaround even during market disruptions.

French CNC companies export to more than 60 countries, supported by multilingual communication channels and efficient transportation networks via Paris, Marseille, and Lyon.

While France excels in engineering sophistication and design optimization, its production costs are generally higher than those in Asia. To remain competitive, many French CNC milling services manufacturers and suppliers build long-term collaborations with Chinese OEM and ODM factories.

These partnerships allow:

- Scalable production: Chinese manufacturers can handle large-volume batch production based on French designs.

- Flexible customization: OEM partners adjust tooling and process parameters to meet unique client requirements.

- Faster market delivery: Global cooperation shortens lead times and ensures better cost performance.

- Mutual quality assurance: Both sides implement cross-inspection processes to maintain high standards.

This hybrid manufacturing model—French design precision combined with Chinese efficiency—creates a balanced value chain that benefits clients worldwide.

The diversity of France's economy ensures wide application for CNC milled components.

- Aerospace: Complex 5-axis structures, turbine housings, wing ribs, and cockpit components.

- Automotive: Engine blocks, brackets, intake manifolds, and gear housings.

- Medical Devices: Surgical instruments, orthopedic implants, and micro-precision components.

- Electronics: Precision housings, heat sinks, and connector frameworks.

- Energy & Defense: Structural supports, enclosures, and heavy-duty mechanical parts.

Each sector requires unique tolerances, materials, and coatings, all of which French manufacturers deliver through multi-process capabilities.

Quality control is a central pillar of French CNC production. Leading suppliers incorporate layered quality assurance systems to monitor every step of the machining process.

- Dimensional inspection: Performed via CMMs, profile projectors, and 3D laser scanners.

- Hardness testing and surface measurement: Ensures performance durability.

- Traceability management: Lot numbers and digital documentation maintain full production history.

- Final sample approval (FAT): Components undergo inspection before shipping, validating safety and precision.

These standards make French parts suitable for high-demand sectors where performance failure is not an option.

When selecting a CNC supplier, decision-makers should evaluate technical and operational criteria carefully:

1. Machine Capability: Determine if the supplier provides 5-axis milling and micro-milling for complex geometries.

2. Material Efficiency: Check compatibility with stainless steel, aluminum, titanium, or composite materials.

3. Engineering Assistance: Look for support in CAD/CAM modeling and design for manufacturability (DFM).

4. Scalability: Assess whether the manufacturer can handle small-batch prototyping as well as mass production.

5. Lead Time: Inquire about turnaround speed and inventory management practices.

6. Sustainability: Prefer suppliers that follow eco-conscious production and waste recycling practices.

7. Customer Support: Responsive communication and after-sales service significantly affect project success.

The next decade will be transformative for CNC milling services manufacturers and suppliers in France. New technologies and sustainability goals are reshaping how components are designed, manufactured, and distributed.

AI-driven monitoring systems can now predict tool failure, adjust feed rates automatically, and extend equipment lifespan, leading to less downtime and higher cost efficiency.

French R&D centers are integrating 3D printing (additive) and CNC milling (subtractive) into unified platforms. This allows parts to be printed roughly and then milled for precision surfaces.

Real-time data dashboards are being used to optimize workflow, identify bottlenecks, and measure energy consumption, improving productivity and sustainability metrics simultaneously.

As automation increases, skilled technicians in France are being retrained in digital modeling, machine learning, and simulation software—ensuring human expertise continues to complement automated systems.

France continues to stand at the forefront of precision engineering, representing one of the most reliable and technologically advanced regions for CNC milling services manufacturers and suppliers. With robust industrial infrastructure, innovative R&D, and strong global partnerships, French CNC suppliers deliver unmatched precision and reliability. Their ability to integrate AI technologies, eco-efficient operations, and flexible OEM collaboration models ensures they remain competitive in the evolving global market.

For international businesses seeking long-term cooperation, France offers a powerful combination of craftsmanship, modernization, and industrial trust that sets the benchmark for CNC milling excellence worldwide.

A1: French suppliers combine precision engineering, strict quality control, advanced automation, and EU-certified sustainability, making them reliable and globally trusted partners.

A2: The primary sectors include aerospace, automotive, medical, defense, and energy industries that require high tolerance and technical reliability.

A3: Yes. Most companies provide OEM/ODM machining, assisting clients with design improvement, prototyping, and tailored production according to specific requirements.

A4: Absolutely. Many suppliers offer digital collaboration, CAD data exchange, and remote project management, ensuring seamless cooperation from prototyping to shipping.

A5: Through automation, efficient tooling systems, and partnerships with international OEM manufacturers (such as Chinese factories), they balance European quality with global cost advantages.

A6: Common certifications include ISO 9001, ISO 14001, AS9100 for aerospace, and IATF 16949 for automotive sectors, ensuring consistent global standards.

A7: Typical French CNC milling operations achieve ±0.005 mm for precision components, depending on material and part size.

Explore South Korea's leading CNC Milling Services Manufacturers and Suppliers. Learn about their technology, expertise, and industries served. Ideal for OEMs, wholesalers, and partners seeking precision engineering and high-quality custom machining solutions.

Discover why Portugal is emerging as a leader among CNC Milling Services Manufacturers and Suppliers. Explore its top machining companies, precision technologies, and global OEM collaborations delivering high-quality, cost-effective components for industries worldwide.

Explore Italy's leading CNC Milling Services Manufacturers and Suppliers. Discover their technical expertise, key companies, industry capabilities, and why global OEMs rely on Italian CNC machining for precision, innovation, and long-term partnership opportunities.

An in-depth look at how CNC milling is transforming manufacturing across the Arab States. This article explores top CNC Milling Services Manufacturers and Suppliers, their technologies, challenges, partnerships, and the growing role of precision machining in regional industrial strategy.

Discover the top CNC milling services manufacturers and suppliers in France. Explore their technology, quality standards, international collaborations, and industry advantages for precision parts manufacturing and OEM production partnerships.

Explore the top 10 Prototype CNC Machining Manufacturers in China. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd., this detailed guide covers their strengths, capabilities, and why Chinese CNC machining companies lead in global innovation and precision manufacturing.

Discover the Top 10 Precision CNC Machining Manufacturers in China, highlighting their strengths, technologies, and OEM capabilities. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd. as a leader, this guide helps global buyers find reliable CNC partners for precision engineering projects.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.

Learn how to post 3D printing services professionally with this comprehensive guide. Discover key steps for building an online presence, optimizing listings, managing orders, pricing smartly, and staying competitive in the fast-growing 3D printing market.

This extended guide explains how to market a 3D printing service through branding, SEO, content creation, social media, partnerships, and client experience. It provides actionable marketing strategies to build trust, improve visibility, and drive growth in a competitive 3D printing industry.

This comprehensive guide explains how to compare 3D printing services by analyzing key aspects such as technology options, materials, quality control, pricing transparency, delivery time, scalability, and security. It helps readers choose reliable providers for both prototypes and production parts.

An in-depth guide to choosing the right 3D printing service. Learn to evaluate technologies, materials, quality standards, and pricing. Perfect for engineers, designers, and entrepreneurs seeking reliable, precise, and cost-effective 3D printing solutions.

Discover how to effectively advertise 3D printing services using SEO, social media, paid campaigns, and branding. This comprehensive guide explains proven marketing strategies to grow your audience, attract clients, and build authority in the evolving 3D printing industry.