From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-14 Origin: Site

Content Menu

● Understanding CNC Milling and Its Role in Modern Manufacturing

● Why Italy Excels in CNC Milling Services

● Top CNC Milling Services Manufacturers and Suppliers in Italy

>> 1. MCM Spa (Machining Centers Manufacturing)

>> 4. Officine Meccaniche Zanetti

>> 7. OMV Spa

● Capabilities and Technical Competence of Italian CNC Milling Services

● Applications Across Major Industries

● How Italian CNC Suppliers Support Global OEMs

● Challenges and Opportunities in the Italian CNC Industry

● Choosing the Right CNC Milling Partner in Italy

● Future Outlook of CNC Milling in Italy

● FAQ – CNC Milling Services Manufacturers and Suppliers in Italy

>> 1. Which industries benefit most from Italian CNC milling services?

>> 2. Do Italian CNC manufacturers accept custom OEM and ODM projects?

>> 3. What quality certifications are common among Italian CNC suppliers?

>> 4. Can Italian CNC suppliers provide high-volume production?

>> 5. How can international buyers contact reliable CNC suppliers in Italy?

>> 6. What advantages do Italian suppliers offer compared to other European producers?

Italy has long been celebrated for its excellence in engineering, industrial design, and high-quality manufacturing. Among its most sophisticated fields, CNC Milling Services Manufacturers and Suppliers play a central role in powering Italy's industrial and export economy. Over the past decades, the country has built a reputation for precision craftsmanship, innovation, and reliability — qualities that position Italian CNC manufacturers among the most trusted partners for global OEMs, wholesalers, and production brands.

In the following article, we take a close look at the evolution of CNC milling in Italy, the top-performing suppliers, their technological strengths, industrial applications, and why international companies increasingly choose Italian firms for outsourced component manufacturing.

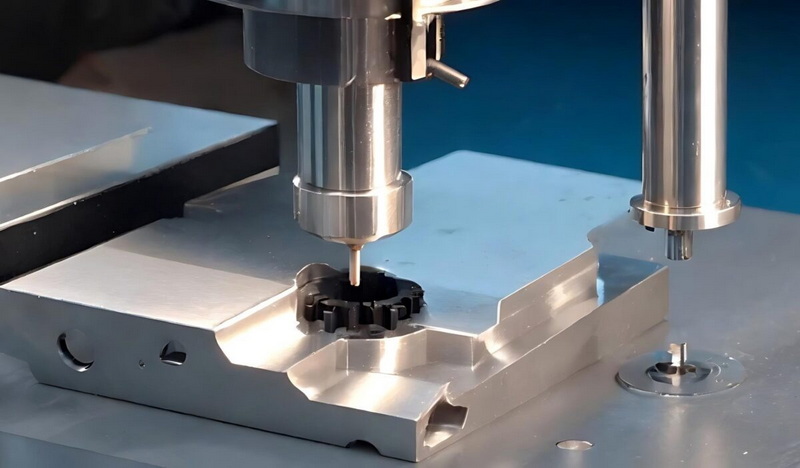

CNC (Computer Numerical Control) milling is one of the most fundamental production processes in contemporary manufacturing. It involves the use of automated rotary cutters guided by digital programming to remove material and shape a workpiece into complex geometries. With capabilities ranging from basic 3-axis to advanced 5-axis machining, CNC milling ensures precision within microns and flexibility across a vast range of materials — including aluminum, stainless steel, brass, titanium, engineering plastics, and composites.

Italian CNC Milling Services Manufacturers and Suppliers bring together computerized automation and deep mechanical knowledge. They transform raw materials into critical parts that meet the demanding specifications of aerospace, automotive, energy, and medical industries. Because of Italy's emphasis on innovation and quality, many local companies also act as R&D partners, helping customers improve designs, reduce costs, and accelerate go-to-market timelines.

Several strategic advantages help Italian CNC manufacturers compete successfully worldwide:

1. Tradition of Mechanical Excellence: Italy's reputation for precision engineering dates back centuries. Regions like Lombardy, Veneto, Piedmont, and Emilia-Romagna are home to dense clusters of mechanical and tooling companies.

2. Advanced Technological Infrastructure: Italian workshops are equipped with advanced CNC machining centers, high-speed spindles, and automated measurement systems.

3. Skilled Human Capital: The country's technical schools and polytechnic universities create a steady pipeline of skilled machinists, designers, and mechanical engineers.

4. Design-Driven Precision: Italian machining firms often integrate industrial design thinking into manufacturing — combining form, function, and durability.

5. International Collaboration: Many Italian CNC Milling Services Manufacturers and Suppliers maintain long-term business relationships with European, North American, and Asian clients, ensuring that their services align with diverse technical and certification standards.

Together, these strengths make Italian CNC suppliers exceptional partners for companies seeking OEM and ODM services that deliver both precision and reliability.

Headquartered in Piacenza, MCM Spa specializes in advanced CNC machining solutions and flexible manufacturing systems. The company serves aerospace, automotive, and energy industries with multi-axis machining capabilities and digital integration. MCM's commitment to precision automation and real-time production tracking positions it as one of the most technologically advanced CNC Milling Services Manufacturers and Suppliers in Europe.

CMS is internationally recognized for its high-speed CNC machining systems and milling services for metal, plastic, and composite materials. Located in Zogno, it supports prototypes, molds, and structural parts manufacturing. Its dynamic adaptation to both small-batch and mass production runs demonstrates Italy's unmatched flexibility in contract machining.

Ferri Group provides complete mechanical machining services, including CNC milling and turning. Its precision metalwork supports energy, marine, and industrial equipment sectors. Through continuous modernization and ISO-certified processes, Ferri Group strengthens Italy's competitive position among CNC Milling Services Manufacturers and Suppliers.

Based in Brescia, Zanetti's reputation for quality and innovation comes from decades of experience in precision part production. Its state-of-the-art CNC machinery handles materials from aluminum and steel to Inconel and custom alloys. The company's small-to-medium batch production caters perfectly to high-mix, low-volume projects.

As both a machine builder and service provider, Meccaniche Lodi bridges the gap between manufacturing and machinery innovation. Its 5-axis CNC machines achieve ultra-fine tolerances, serving industries that demand dimensional perfection such as semiconductor and robotics manufacturing.

Founded in 1922, Gnutti Carlo is a cornerstone of Italian mechanical manufacturing. Specializing in hydraulic, automotive, and industrial components, it integrates automated CNC milling lines with robotic loading systems. This makes Gnutti Carlo one of the most efficient CNC Milling Services Suppliers when it comes to balancing high precision with mass production.

OMV operates advanced milling centers for mechanical, aerospace, and defense applications. Its engineering department collaborates directly with clients to co-develop part geometries that enhance functionality and manufacturability. That deep technical partnership is a hallmark of Italian service culture in precision machining.

OMG Zanoletti focuses on large-dimension CNC milling and tooling production. Its facilities can handle complex components for shipbuilding, wind power, and heavy machinery. The company's ability to maintain accuracy across large-scale parts highlights Italy's diversity in CNC capabilities.

Bianchi Industrial is an integrated service provider offering precision CNC milling, grinding, and assembly for automation and packaging industries. Its combination of high-speed machining and lean production systems ensures minimal waste and maximum process stability.

The hallmark of Italian CNC Milling Services Manufacturers and Suppliers lies in their precision, versatility, and technical breadth. They provide end-to-end production that typically includes:

- CAD/CAM and design support to refine models and optimize performance.

- 5-axis simultaneous machining for complex geometries and reduced setups.

- Prototyping and pilot production with fast turnaround times.

- Automated tool calibration and quality inspection using CMM and laser scanning methods.

- Surface finishing and secondary operations such as anodizing, plating, and painting.

Raw materials frequently processed include aluminum 6061/7075, stainless steels (303, 304, 316), titanium alloys, carbon steel, and engineering plastics like PEEK and POM. Many factories implement real-time production monitoring and predictive maintenance systems to ensure reliability and precision consistency across all manufacturing cycles.

Italy's CNC machining expertise finds applications in numerous sectors:

- Aerospace: Turbine housings, brackets, and aircraft body components that require high strength-to-weight ratios.

- Automotive: Cylinder heads, gear housings, engine blocks, and precision transmission parts.

- Medical Devices: Surgical instruments, orthopedic implants, and diagnostic equipment housings.

- Energy: Components for turbines, compressors, and renewable energy systems.

- Electronics and Robotics: Sensor housings, connectors, and mechanical arm joints.

This cross-industry versatility demonstrates how Italian suppliers can adapt CNC milling technologies to a wide variety of project scales and complexity levels.

Many international manufacturers — particularly OEMs and production partners from Asia, North America, and Europe — collaborate with Italian CNC machining companies for outsourced manufacturing. The main reasons include:

1. Multi-Disciplinary Expertise: Italian engineers combine materials science, mechanical design, and precision machining knowledge.

2. International Certifications: Most suppliers comply with ISO 9001, ISO 14001, and AS9100 standards.

3. OEM/ODM Partnership Experience: Italian suppliers work seamlessly with foreign brands to co-design and custom-manufacture parts under private label arrangements.

4. Supply Chain Integration: Their ability to manage logistics, packaging, and export documentation simplifies cross-border operations.

5. Competitive Cost-to-Quality Ratios: Despite operating within the EU, lean manufacturing and automation allow Italian firms to remain cost-effective.

In addition, many Italian manufacturers provide multilingual sales and engineering support, ensuring clear communication with customers worldwide. This international orientation strengthens their position as trusted CNC Milling Services Manufacturers and Suppliers to global brands.

While Italy enjoys a strong position in precision machining, its companies also face several challenges — and exciting opportunities:

- Rising Automation Costs: Balancing automation investment with cost efficiency requires strategic planning.

- Talent Shortages: Continuous technical training is key to maintaining world-class skill levels.

- Supply Chain Resilience: Italian companies are increasingly diversifying supplier networks and using digitalization to predict disruptions.

- Green Manufacturing: There is growing emphasis on sustainability, recycling, and energy-efficient machining.

Despite these challenges, Italy's combination of innovation and craftsmanship continues to give its CNC manufacturers a distinct edge. Many companies are now leveraging Industry 4.0 technologies — combining robotics, AI-driven programming, and data analytics to achieve “smart factories” capable of near-zero defects.

For buyers seeking reliable CNC Milling Services Manufacturers and Suppliers, a structured supplier selection process is critical:

1. Evaluate Technical Capability: Ensure the supplier has the right machining centers, inspection tools, and software systems for your requirements.

2. Review Case Studies or References: Reliable partners can demonstrate prior success in similar industries or part geometries.

3. Assess Communication Competency: Transparent project management reduces production risk.

4. Check Certifications and Audits: Confirm compliance with relevant international standards.

5. Start with Trial Orders: Small pilot projects help verify product quality and efficiency.

When these factors are thoroughly reviewed, partnering with Italian CNC suppliers can lead to long-term value creation, improved product design, and access to European markets.

The future of Italy's CNC milling sector looks promising. Several trends are expected to drive industry growth through the next decade:

- Additive Manufacturing Integration: Hybrid CNC and 3D printing systems that improve prototyping and reduce waste.

- Smart Manufacturing Ecosystems: Networking multiple CNC machines under AI-driven control systems for predictive efficiency.

- Sustainability Initiatives: Reusing metal chips, adopting ecological coolants, and optimizing energy consumption.

- Customization and Rapid Engineering: Offering shorter lead times and more personalized part manufacturing for international clients.

- Collaborative Supply Chains: Expanding partnerships between Italian suppliers and Asian manufacturers for global project coordination.

As these innovations continue to reshape the manufacturing landscape, Italy remains a central hub for precision machining excellence — blending technology, creativity, and tradition into every component it produces.

Italian CNC Milling Services Manufacturers and Suppliers exemplify precision, innovation, and craftsmanship at the highest level. From high-speed milling for aerospace structures to intricate medical device components, their expertise ensures world-class results in both technical excellence and aesthetic refinement. Backed by advanced digital tools, skilled engineers, and a deeply rooted tradition of mechanical mastery, Italy continues to lead globally in CNC precision manufacturing. For international OEMs and brand owners seeking a reliable, high-quality, and creative engineering partner, Italy stands as one of the most strategic destinations in the modern supply chain.

Aerospace, automotive, medical, industrial machinery, and renewable energy sectors are the main beneficiaries of Italy's precision machining expertise.

Yes. Many suppliers provide comprehensive design assistance, rapid prototyping, and full-scale production under OEM or ODM cooperation frameworks.

ISO 9001, ISO 14001, and AS9100 certifications are widely held. Some suppliers also maintain IATF 16949 certification for automotive applications.

While many focus on small and medium batches, leading Italian manufacturers effectively handle high-volume orders thanks to automation and multi-station production lines.

Professional directories, trade exhibitions such as BI-MU Milan, or platforms like Europages and Alibaba can connect buyers with vetted Italian suppliers.

Their unique blend of engineering innovation, design expertise, flexible production capacity, and personalized customer service sets them apart from competitors in Germany or Eastern Europe.

Is CNC machining expensive? This detailed guide breaks down every factor influencing CNC cost—from materials and machine time to tolerances and production volume—while offering expert strategies to reduce expenses and maximize manufacturing efficiency.

This in-depth article explores whether CNC machining is dangerous, detailing potential hazards, critical safety measures, advanced automation, and operator best practices. It also covers regulatory standards, sustainability, and includes a comprehensive FAQ on CNC safety management.

This comprehensive article examines whether CNC machining qualifies as blue-collar work. It traces the role's history, skills, and education, highlighting its evolution into a gray-collar profession that fuses craftsmanship, technology, and digital competence in modern manufacturing.

This article explores whether CNC machining is a dying trade. It concludes that far from disappearing, CNC machining is evolving with automation, AI, and Industry 4.0 integration. The trade remains vital to global manufacturing, offering lasting opportunities for innovation and skilled careers.

This complete guide explains how to start and grow a CNC machining business — from planning, financing, and equipment selection to marketing, automation, and sustainability. Learn expert strategies to build a profitable precision manufacturing company in today's competitive market.

Explore South Korea's leading CNC Milling Services Manufacturers and Suppliers. Learn about their technology, expertise, and industries served. Ideal for OEMs, wholesalers, and partners seeking precision engineering and high-quality custom machining solutions.

Discover why Portugal is emerging as a leader among CNC Milling Services Manufacturers and Suppliers. Explore its top machining companies, precision technologies, and global OEM collaborations delivering high-quality, cost-effective components for industries worldwide.

Explore Italy's leading CNC Milling Services Manufacturers and Suppliers. Discover their technical expertise, key companies, industry capabilities, and why global OEMs rely on Italian CNC machining for precision, innovation, and long-term partnership opportunities.

An in-depth look at how CNC milling is transforming manufacturing across the Arab States. This article explores top CNC Milling Services Manufacturers and Suppliers, their technologies, challenges, partnerships, and the growing role of precision machining in regional industrial strategy.

Discover the top CNC milling services manufacturers and suppliers in France. Explore their technology, quality standards, international collaborations, and industry advantages for precision parts manufacturing and OEM production partnerships.

Explore the top 10 Prototype CNC Machining Manufacturers in China. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd., this detailed guide covers their strengths, capabilities, and why Chinese CNC machining companies lead in global innovation and precision manufacturing.

Discover the Top 10 Precision CNC Machining Manufacturers in China, highlighting their strengths, technologies, and OEM capabilities. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd. as a leader, this guide helps global buyers find reliable CNC partners for precision engineering projects.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.