From idea to market-ready product, our NPI solutions make every stage easier, faster. Discover How We Help

Views: 222 Author: Tomorrow Publish Time: 2025-12-15 Origin: Site

Content Menu

● Choosing the Right CNC Machines

● Recruiting and Training Skilled Employees

● Developing a Marketing Strategy

● Pricing Strategy and Profit Margins

● Managing Operations and Quality Control

● Legal Compliance and Risk Management

● Digitalization and Automation Trends

● Scaling and Diversifying Your CNC Business

● FAQ

>> 1. What basic equipment do I need to start a CNC business?

>> 2. How profitable is CNC machining?

>> 3. What skills are crucial for CNC entrepreneurs?

>> 4. How do I market my CNC services effectively?

>> 5. What are future trends in CNC machining?

Starting a CNC machining business is an exciting and potentially lucrative opportunity for entrepreneurs who have technical expertise, problem-solving abilities, and a passion for manufacturing. With global demand for precise, customized components growing rapidly, especially in industries like aerospace, automotive, medical devices, and electronics, now is an excellent time to explore this field.

However, success in CNC machining requires more than just purchasing machines and chasing clients. It demands careful planning, knowledge of machining technologies, a sound business strategy, and continuous investment in skills, quality, and customer relationships. This comprehensive guide breaks down every essential step to help you confidently launch and grow your CNC machining business.

CNC stands for Computer Numerical Control. It refers to using computerized systems to operate various manufacturing tools such as mills, lathes, grinders, and routers. The process starts with a digital design, usually created using CAD (Computer-Aided Design) software, which is then converted into a set of machine instructions via CAM (Computer-Aided Manufacturing) software. These instructions, called G-code, guide the machining tool's movements to create accurate, consistent parts.

CNC machining is highly valued for its precision, repeatability, and speed, making it the backbone of modern manufacturing processes. It supports rapid prototyping, mass production, and custom fabrication with tight tolerances that are hard to achieve manually. Whether creating engine components, surgical instruments, or aerospace brackets, CNC machining ensures every piece meets exact specifications.

Before spending money on machines or leasing a workshop, you must evaluate market demand. Identifying your niche helps position your business strategically.

Industries and market segments to consider include:

- Aerospace: Components that require extreme precision and certified materials.

- Automotive: Engine blocks, gear systems, or tooling for production lines.

- Medical: Surgical tools, implants, and diagnostic instrument parts.

- Consumer Electronics: Aluminum and plastic housings for devices.

- Industrial Equipment: Customized parts for machinery and automation systems.

To validate your idea, perform detailed market research using sources such as industry reports, trade directories, and supplier networks. Engage potential clients early to understand their production needs and budget constraints. Identifying underserved sectors or specific problems (like fast prototyping or low-volume custom work) gives you a competitive edge.

Your business plan serves as a blueprint for the entire operation. It not only attracts investors or lenders but also helps guide your decisions.

Include the following core sections:

1. Executive Summary: Your mission, goals, and the value you bring to clients.

2. Company Overview: How your shop will operate and what makes it unique.

3. Market Research: Target markets, customer needs, and competitor analysis.

4. Service Offerings: Types of parts, materials, and machining services provided.

5. Operations Plan: Details on equipment, workflow, suppliers, and staffing.

6. Financial Plan: Include cost projections, break-even analysis, and cash flow.

7. Marketing Strategy: Define branding, advertising, and customer outreach.

8. Growth Roadmap: Future expansion plans like automation or new services.

A clear business plan shows potential partners and clients that you're serious, prepared, and capable of sustaining operations long-term.

Starting a CNC shop requires a notable upfront investment. The capital depends on the scale of operations, number of machines, and your facility's size.

Typical startup costs include:

- CNC machines ($30,000–$200,000 each depending on type and axis count).

- CAD/CAM software subscriptions or licenses.

- Workshop setup and utilities such as three-phase electrical power.

- Raw materials (metal alloys, plastics, composites).

- Cutting tools, measuring devices, and inspection systems.

- Business insurance and certifications.

- Marketing and website development.

Funding options:

- Traditional bank loans or credit lines.

- Equipment leasing or financing programs.

- Small Business Administration (SBA) loans.

- Angel investors or silent partners.

- Government grants for manufacturing innovation.

Careful budgeting ensures you maintain cash flow for ongoing costs such as maintenance, tooling replacement, and employee wages.

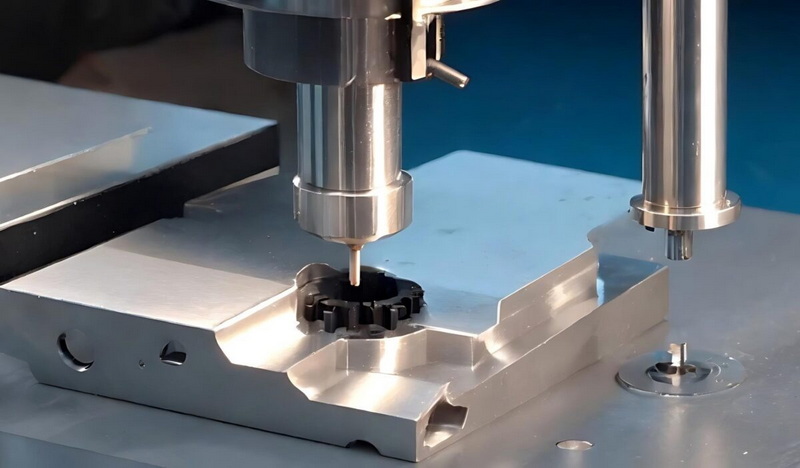

The machines you purchase define your capabilities and quality standards. Select machines that match your target market and long-term business vision.

CNC machine categories:

- CNC Milling Machines: Handle 3-to-5-axis cutting for complex shapes.

- CNC Lathes: Create cylindrical components efficiently.

- CNC Routers: Ideal for softer materials like wood, plastic, or composites.

- CNC Plasma/Laser Cutters: Offer precision cutting for flat materials.

- Multi-axis and Swiss-type Machines: Enable simultaneous operations for high-speed precision.

When evaluating machines, consider accuracy, software compatibility, available support service, and spare parts supply. It's often wiser to start with one or two versatile machines and expand as customer orders grow.

A well-planned workspace ensures safety, productivity, and scalability. Your facility should meet safety and environmental standards while maximizing workflow efficiency.

Key workspace features:

- Proper layout for raw material storage, machining, assembly, and inspection.

- Sufficient power capacity with backup systems.

- Dust and chip extraction systems for clean air quality.

- Soundproofing and lighting for worker comfort.

- Safety measures including fire extinguishers, emergency exits, and signage.

An ergonomic and well-organized shop floor reduces downtime, minimizes operator fatigue, and improves overall throughput.

A CNC business is only as strong as the team that runs it. Skilled machinists, programmers, and quality inspectors are indispensable.

Critical roles include:

- CNC Operators: Handle daily machine programming, setup, and monitoring.

- Design Engineers: Create CAD models and optimize for manufacturing.

- Quality Technicians: Ensure all parts meet client specifications.

- Maintenance Staff: Keep machines in peak performance.

Investing in continuous training strengthens competitiveness. Encourage courses in CAD/CAM software, G-code programming, and precision measurement techniques. Strong teamwork between engineers and machinists increases accuracy and reduces waste.

Marketing determines how efficiently you attract and retain customers. Focus on building trust, visibility, and credibility.

Smart marketing practices:

- Build a website showcasing portfolios, client testimonials, and certifications.

- Use SEO techniques and industry-specific keywords such as “precision CNC parts” or “rapid prototyping services.”

- Promote on professional networks (LinkedIn, ThomasNet, Xometry).

- Attend trade fairs, conferences, and maker expos.

- Offer discounts for prototype runs to onboard new clients.

Word-of-mouth remains one of the strongest marketing methods in B2B manufacturing, so focus on consistent quality and timely deliveries.

Setting prices correctly is crucial for profitability and client trust. Pricing too high may drive customers away; pricing too low limits growth.

Factors influencing price:

- Material cost and availability.

- Machine run-time and operator labor.

- Tool wear and replacement frequency.

- Setup and inspection time.

- Post-processing services (anodizing, polishing, packaging).

- Overhead such as rent, electricity, and maintenance.

Many shops use hourly machine rate models, calculated by dividing operational costs by anticipated machine use hours. Reviewing competitor pricing and monitoring profitability regularly ensures sustainable growth.

Efficient operations and strict quality control set you apart in a competitive market. Every batch produced must meet agreed specifications.

Best practices:

- Implement lean manufacturing and just-in-time production.

- Maintain clean workspace standards to prevent contamination.

- Schedule preventive maintenance for all machines.

- Adopt digital tracking for job progress and inventory control.

- Use Coordinate Measuring Machines (CMM) for precise inspections.

Investing in ISO 9001 certification can increase credibility and open access to larger corporate contracts.

Operating legally protects your reputation and reduces risk.

Steps to take:

- Choose a legal entity such as LLC or corporation.

- Obtain appropriate business permits and manufacturing licenses.

- Carry general liability, workers' compensation, and equipment insurance.

- Protect proprietary designs with Non-Disclosure Agreements (NDAs).

- Ensure environmental compliance for waste management and noise control.

Risk management also involves having backup power solutions and cybersecurity protocols for design data protection.

To stay competitive, modern CNC businesses must embrace Industry 4.0 technologies. Integrating automation, data analytics, and smart manufacturing improves efficiency and decision-making.

- IoT Monitoring: Real-time performance tracking and predictive maintenance.

- AI-based Design Optimization: AI tools help create more efficient toolpaths.

- Cloud-based Collaboration: Simplifies file sharing and client approvals.

- Cobot Integration: Collaborative robots assist in repetitive operations.

Digital transformation not only enhances productivity but also attracts clients seeking high-tech, responsive vendors.

Today's clients increasingly value sustainability. CNC businesses can improve their environmental footprint through mindful operations.

Eco-friendly initiatives:

- Recycling metal shavings and scrap materials.

- Using lubricant-free or biodegradable cutting fluids.

- Installing high-efficiency motors and LED lighting.

- Minimizing water and electricity consumption through smart controls.

Sustainability not only benefits the planet but can also cut operational costs and create a positive brand reputation.

Once operations stabilize, consider expanding your production scope.

You can scale by:

- Adding new machine types or automation solutions.

- Offering design consulting or assembly services.

- Opening satellite workshops closer to key clients.

- Partnering with R&D labs or educational institutions.

Diversification may include hybrid manufacturing (CNC + 3D printing), metal finishing, or low-volume production for specialized markets like robotics or renewable energy.

Launching a CNC machining business merges craftsmanship with entrepreneurship. While initial investments and challenges can be daunting, a well-planned approach—founded on quality, precision, and innovation—can yield excellent long-term rewards.

Focusing on skilled personnel, advanced technology, client relationships, and consistent improvements ensures sustainability and profitability. In an era defined by digital precision and global outsourcing, your CNC shop can stand out as a local hub of reliability, speed, and craftsmanship.

You'll need at least one CNC milling or turning machine, CAD/CAM software, precision measuring tools, raw materials, and safety equipment. Optional equipment includes coolant systems, tool changers, and inspection stations.

Profit margins typically range between 10% and 30% depending on specialization, efficiency, and material costs. High-end machining services like aerospace or medical work can yield greater margins.

Essential skills include CAD/CAM programming, mechanical design understanding, business management, pricing strategy, and client communication. Being detail-oriented is critical in this precision-based field.

Focus on online marketing, professional networking, and B2B collaboration. A well-structured website, strong SEO strategy, and partnerships with design engineers or suppliers can bring steady clients.

Automation, hybrid manufacturing, IoT integration, and AI-enhanced toolpaths define the next phase of CNC technology. Businesses adopting these smart solutions will enjoy increased speed, flexibility, and cost savings.

Is CNC machining expensive? This detailed guide breaks down every factor influencing CNC cost—from materials and machine time to tolerances and production volume—while offering expert strategies to reduce expenses and maximize manufacturing efficiency.

This in-depth article explores whether CNC machining is dangerous, detailing potential hazards, critical safety measures, advanced automation, and operator best practices. It also covers regulatory standards, sustainability, and includes a comprehensive FAQ on CNC safety management.

This comprehensive article examines whether CNC machining qualifies as blue-collar work. It traces the role's history, skills, and education, highlighting its evolution into a gray-collar profession that fuses craftsmanship, technology, and digital competence in modern manufacturing.

This article explores whether CNC machining is a dying trade. It concludes that far from disappearing, CNC machining is evolving with automation, AI, and Industry 4.0 integration. The trade remains vital to global manufacturing, offering lasting opportunities for innovation and skilled careers.

This complete guide explains how to start and grow a CNC machining business — from planning, financing, and equipment selection to marketing, automation, and sustainability. Learn expert strategies to build a profitable precision manufacturing company in today's competitive market.

Explore South Korea's leading CNC Milling Services Manufacturers and Suppliers. Learn about their technology, expertise, and industries served. Ideal for OEMs, wholesalers, and partners seeking precision engineering and high-quality custom machining solutions.

Discover why Portugal is emerging as a leader among CNC Milling Services Manufacturers and Suppliers. Explore its top machining companies, precision technologies, and global OEM collaborations delivering high-quality, cost-effective components for industries worldwide.

Explore Italy's leading CNC Milling Services Manufacturers and Suppliers. Discover their technical expertise, key companies, industry capabilities, and why global OEMs rely on Italian CNC machining for precision, innovation, and long-term partnership opportunities.

An in-depth look at how CNC milling is transforming manufacturing across the Arab States. This article explores top CNC Milling Services Manufacturers and Suppliers, their technologies, challenges, partnerships, and the growing role of precision machining in regional industrial strategy.

Discover the top CNC milling services manufacturers and suppliers in France. Explore their technology, quality standards, international collaborations, and industry advantages for precision parts manufacturing and OEM production partnerships.

Explore the top 10 Prototype CNC Machining Manufacturers in China. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd., this detailed guide covers their strengths, capabilities, and why Chinese CNC machining companies lead in global innovation and precision manufacturing.

Discover the Top 10 Precision CNC Machining Manufacturers in China, highlighting their strengths, technologies, and OEM capabilities. Featuring Shenzhen Feifan Hardware & Electronics Co., Ltd. as a leader, this guide helps global buyers find reliable CNC partners for precision engineering projects.

Explore the top 10 Custom CNC Machining Manufacturers in China, led by Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about each company's strengths, capabilities, and quality standards to find the ideal CNC machining partner for your custom OEM projects.

China's top Rapid CNC Machining Manufacturers, led by Shenzhen Feifan Hardware & Electronics Co., Ltd., lead the world in precision, quality, and speed. This article reviews the top 10 companies driving China's rapid manufacturing future through innovation and advanced CNC technology.

Explore the top 10 Laser Engraving Services Manufacturers in China, featuring industry leader Shenzhen Feifan Hardware & Electronics Co., Ltd. Learn about capabilities, OEM customization, and key factors for choosing the best laser engraving partner for your business.

This detailed guide explains every step for setting a CNC turning machine—from preparation and workpiece mounting to tooling, programming, testing, and maintenance. Ideal for machinists seeking precision, safety, and efficiency in CNC turning operations.

Learn step-by-step how to make a CNC turning program in Hindi. Understand G-codes, M-codes, roughing and finishing cycles, and advanced techniques for precision machining. Perfect for Hindi-speaking students, machinists, and beginners in CNC operation.

This detailed guide explains step-by-step how to build a CNC turning machine, from mechanical design to electronic integration and software setup. It covers calibration, maintenance, safety, and troubleshooting, offering a comprehensive roadmap for engineers and hobbyists alike.

This extended guide thoroughly explains how to lock speed and feed in Fanuc CNC turning machines using parameters, custom M-codes, ladder logic, and password protection. It provides step-by-step instructions, troubleshooting advice, and best practices to achieve greater process stability and quality control.

This comprehensive guide explains how to perform eccentric turning on CNC machines, covering setup, programming, balancing, tooling, inspection, and safety. It includes examples, troubleshooting tips, and FAQs to help machinists achieve accurate, vibration-free eccentric machining operations.